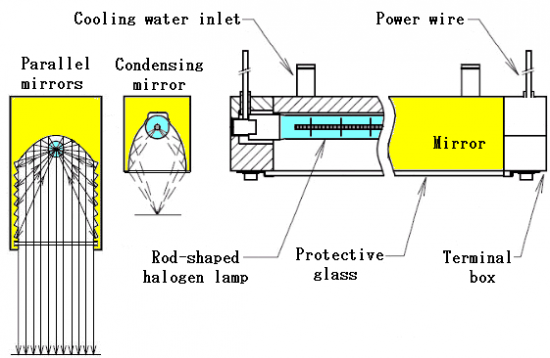

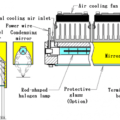

[Basic structure of Halogen Line Heater]

Halogen Line Heater consists of cooling unit, lamp unit, Condensing mirror unit, terminal box, and protective glass.

Most of the composition covers an elongated lamp and is occupied by a condensing mirror.

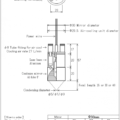

Quartz glass is used for the lamp, and there are three types of tube diameters: Φ10, Φ13, and Φ18.

The current capacity of the lamp can be arbitrarily designed up to the power supply voltage and output of 25kw based on the limit value of 25A.

The maximum length of the lamp is 2,500 mm.

The electric wire uses a special heat-resistant electric wire (silicone rubber / glass cloth coating).

The material of the condensing mirror is gold-plated Aluminium.

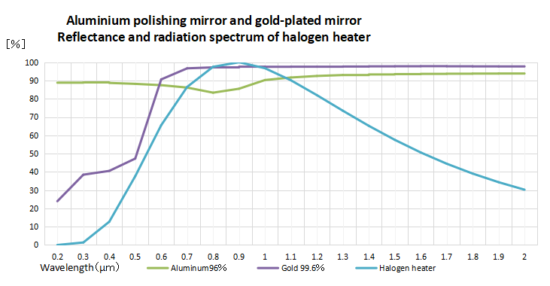

Gold-plated condensing mirrors can most effectively reflect the light of halogen lamps.

Although the heating power is reduced by 10%, it is also possible to select an Aluminium polishing mirror with good cost performance.

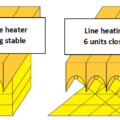

There are two types of condensing mirrors, one for linear heating and the other for plane heating.

A protective glass that prevents gas and scattering from the object to be heated can be attached to the condensing mirror as an option.

Use the standard line heater with the longitudinal direction horizontal. This is because if the line heater is installed vertically, the filament of the lamp will be overloaded.

When installing the line heater vertically, install a vertical lamp.

Avoid applying vibration or impact as much as possible. If the impact is strong, it may damage the quartz tube or break the filament.

Even if the filament has no visible evidence of metal fatigue or deformation, it may be metal fatigued or deformed. In this case, even if the effective value is less than the rated voltage, a high voltage is applied momentarily, which may cause dielectric breakdown in the lamp, resulting in disconnection or explosion.

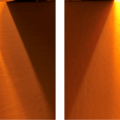

Gold-plated mirror and Aluminium polishing mirror

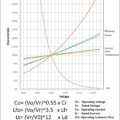

Gold-plated condensing mirrors can most effectively reflect the radiant energy of halogen lamps.

However, the plating of the Condensing mirror may be separated due to the scattering of gas and particles generated from the object to be heated.

If it peals off, the reflectance will decrease and it will be necessary to replace the condenser.

Aluminium-polished condensing mirrors have up to 10% lower reflectance than gold-plated ones.

In addition, the surface of the Condensing mirror gradually oxidizes and the reflectance gradually decreases.

Unlike gold-plated mirrors, by re-polishing the mirror plane, the decrease in reflectance due to oxidation can be suppressed and restored.

Regardless of which Condensing mirror is used, it is essential to keep condensing millor clean and maintain the reflectance for efficient heating.

A protective glass can be attached to the condensing mirror as an option.

By installing a protective glass, it is possible to prevent contact with oil smoke on the reflecting plane of the condensing mirror and scattering of particles.

Furthermore, after installing the protective glass, there is also a method of supplying compressed air to the inside of the condensing mirror to make it positive pressure and prevent the intrusion of dust and oil smoke.

If air leaks are a problem, a closed structure can solve them.

<< Difference between standard Aluminium polished condensing mirror and gold-plated condensing mirror >>

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop