Halogen Point Heaters convert the electricity of halogen lamps into light,

A heater that uses a Condensing mirror to concentrate the light in dots and circles and heat it at a high temperature.

◎ Since it heats directly without a heat medium, the sample can be heated through glass or in a vacuum.

◎ It can be heated cleanly from room temperature to 1700℃.

◎ It will start up in about 3 seconds. It is economical because idling time is saved.

◎ The voltage can be changed at all times, making it suitable for PID control.

△ The amount of heat absorption changes depending on the infrared absorption rate, colour, and plane condition of the object to be heated.

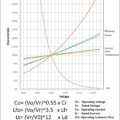

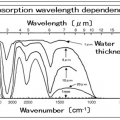

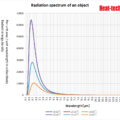

The wavelength distribution of halogen lamps is in the visible to near infrared range of 500nm~2500nm.

Even within the near-infrared region, the peak wavelength of halogen lamps is approximately 900nm~1000μm.

Therefore, the closer the infrared absorption region of the object to be heated is to the near infrared region, the higher the infrared absorption rate and the better the heating efficiency.

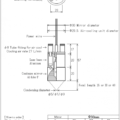

The dedicated condensing mirror is equipped with a gold-plated condensing mirror with the highest reflection efficiency.

The rated values of the “focusing distance” and “focal diameter” of the condensing mirror are the values that can obtain the maximum temperature.

User can change the size of the focal diameter by changing the focusing distance,

Higher temperature heating is possible when the focal length (distance from the end of the condensing mirror to the object to be heated) is shorter.

The limit value for the current capacity of the lamp is 25A, and the maximum is 120V-3kw.

There is a “Re-reflex Heating Method” as a method for heating more efficiently.

The rereflection heating method uses a reflective material to refocus the light that was not focused.

It is a method of heating uniformly at high temperature.

* Custom-made products can be manufactured after special design, but from the viewpoint of price and delivery time,

It is recommended to consider whether the standard product can be used by shifting the focal length.

About clean room specifications

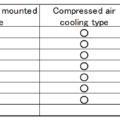

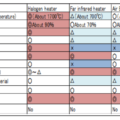

There are two types of Halogen Point Heaters, general specification products and clean specification products.

For clean room specifications, the electric lines are replaced with Teflon electric lines, and the usage fee of the adhesive for fixing the lamp is suppressed as much as possible.

Forced cooling is recommended because the temperature of the lamp base tends to be higher than that of general specifications.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop