INDEX

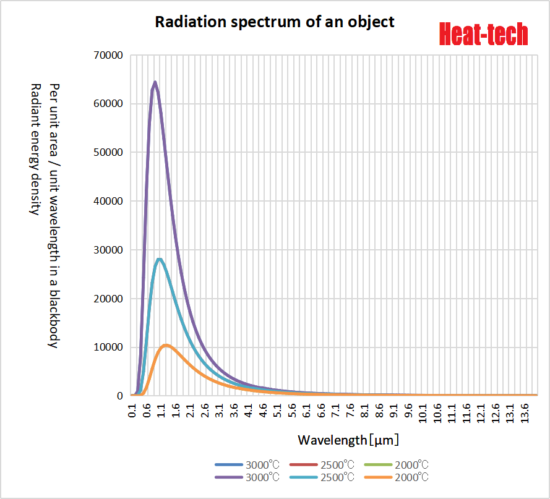

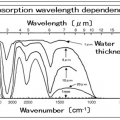

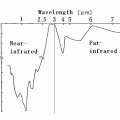

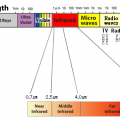

A halogen heater is used for radiant heating of near infrared rays. Of the electromagnetic waves radiated from a heating element at about 3000℃, the maximum wavelength is about 1μm in the near infrared region. A convex parabola is drawn with the maximum wavelength at the apex and radiated from short wavelengths to long wavelengths.

Halogen heaters can also be used for radiant heating of far infrared rays. This is because the halogen heater also contains radiation in the far infrared region. It can be seen from the graph that the higher the object temperature, the higher the radiant energy density at all wavelengths. The longer the wavelength, the less advantageous it is.

Halogen heaters can also change the peak wavelength from near infrared rays to far infrared rays by adjusting the output, but it is difficult to control the filament temperature and it is difficult to adjust the output to any temperature (maximum wavelength). Far-infrared heaters can do that depending on the type of heating element.

In conclusion, near-infrared heating halogen heaters are suitable for high temperature heating and instantaneous heating. This is because the heating element temperature can be raised to a high temperature and the rise time is faster than that of a far-infrared heater. Since the heating element temperature of the far-infrared heater is low, the difference between the peak wavelength and other wavelengths is gradual. Due to this characteristic, it is suitable for heating uneven objects and objects that cannot be heated at high temperatures.

Heating example to select a near-infrared heater

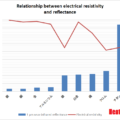

Example 1. In the case of metal, a halogen heater is advantageous because radiation with a shorter wavelength generally has a higher absorption rate. When heating with a far-infrared heater, the temperature rises to a certain level due to the difference in wavelength and density, but it does not rise to the heating temperature of the halogen heater.

Example 2, if the external dimensions of the heater are the same, a halogen heater with a short wavelength and high output is generally advantageous. It is difficult to heat with high output with a far infrared heater, and it does not rise to the heating temperature of a halogen heater.

Heating example to select a far-infrared heater

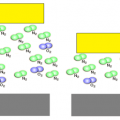

Example 1: When white paper with black letters printed on it is heated with a far-infrared heater, the overall temperature rises relatively. In the case of a near-infrared heater, the black letters are heated more strongly than the other white areas, causing unevenness in the heated areas. The cause of this is that the infrared absorption rate differs depending on the colour, and the near-infrared heater has a high heating element temperature and the difference between the maximum wavelength and other wavelengths is large.

Example 2: When the painted material is heated with a far-infrared heater, the entire painted paint is dried. In the case of a near-infrared heater, the plane of the paint is dry, but the inside is not completely dry. The cause of this is the difference in energy density between the near-infrared heater and the far-infrared heater. Naturally, the near-infrared heater, which has a higher heating element temperature, has a higher density, so it dries faster, but since it lights up instantly, there is a difference between the plane and the inside.

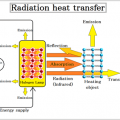

Light emitted from a lamp and incident on an object is partially reflected and partially absorbed by a normal opaque object. The absorbed light contributes to heating. By covering the light reflected from the object with a dome-shaped material with high reflectance, the light reflected from the object is re-reflected and incident on the object, and some light is absorbed again. By repeating this cycle, Efficient heating is possible in a short time. It is best to cover the object in a dome shape, but it is also effective to just surround the object.

This method is called the “reflex heating method”. For details, refer to the “Reflex heating method” page.

In order to heat efficiently, the key points are in what wavelength range the superheated object has a high absorptivity (emissivity) and to what temperature the superheated object is heated. For example, quartz glass is a substance that transmits ultraviolet rays, visible light, and infrared rays widely, but the transmittance of infrared rays exceeding 4 μm drops to around 0. Far-infrared wavelengths are advantageous for heating quartz glass.

An ideal substance with 100% absorption at all wavelengths is called a blackbody. According to Planck’s law, the maximum wavelength shifts in the far-infrared direction when the object temperature is low, and in the near-infrared direction when the object temperature is high. The maximum wavelength of a blackbody with an absorption rate of 4 μm is 451 ℃. When the heating temperature is 451 ℃, adjusting the maximum wavelength to 4 μm enables very efficient heating, but heating above 451 ℃ is possible. Can not.

The higher the blackbody temperature, the higher the radiant energy density at all wavelengths, including the maximum wavelength, than at lower heating element temperatures. Therefore, in high temperature heating, the higher the object temperature, the more advantageous. The radiation of the tungsten filament, which is the heating element of the halogen heater, mostly matches the blackbody radiation. In other words, it can be said that halogen heaters are suitable for high-temperature heating even when heating in the far-infrared region.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop