[ Problem Point ] We were in trouble because there was no space where BLOWER which transfers cooling water after the back weld pulled out is installed. [ ⇒Kaizen Point ] It was dried at high temperature by the Power ...

Read More »No.13 Dryness of printed matter

[ Problem Point ] Air blow dry was being done in room temperature,but we were in trouble because it wasn’t dried. [ ⇒Kaizen Point ] Air blow dry was done by the Air Blow Heater.It was appropriate temperature control and ...

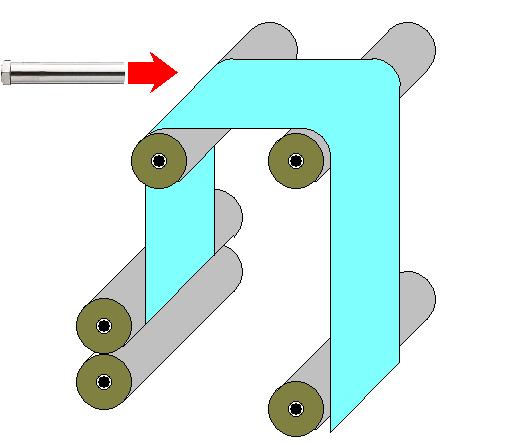

Read More »No.12 Dryness of a coater

[ Problem Point ] Air blow dry was being done in room temperature,but we were in trouble because it wasn’t dried. [ ⇒Kaizen Point ] Air blow dry was done by the Air Blow Heater. It was appropriate temperature control ...

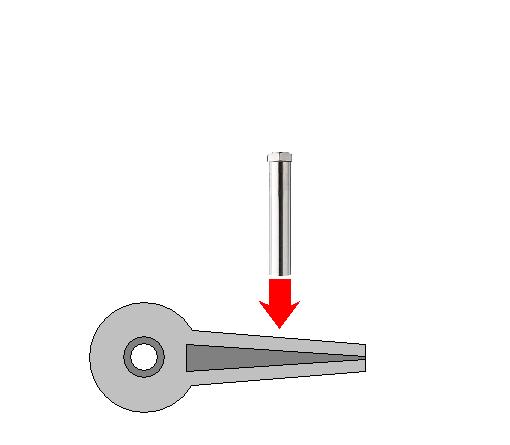

Read More »No.11 Heating cutoff of resin seat

[ Problem Point ] Resin seat was cut by a blade, it comes loose from the end,and we were in trouble. [ ⇒Kaizen Point ] Hot wind was narrowed down to a pinpoint by the taper type of the Air ...

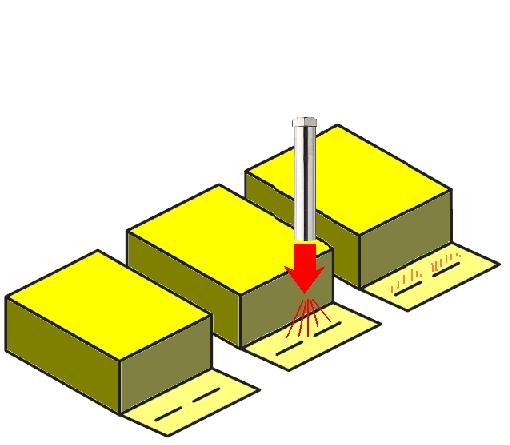

Read More »No.10 Take aluminum Jaggy

[ Problem Point ] Grinder was being used for deburring of aluminum die casting. Hairline can’t leave remaining gloss for the surface. [ ⇒Kaizen Point ] Spot was heated by the Air Blow Heater. and it was deburred. We could ...

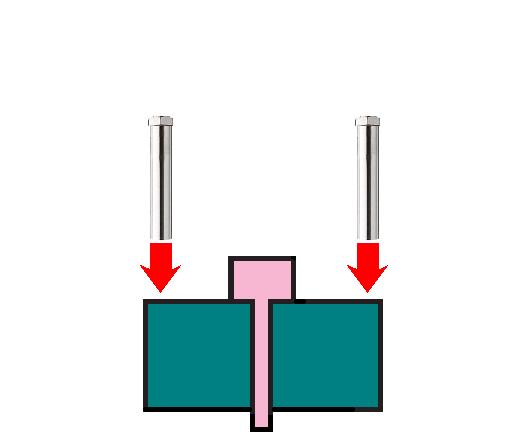

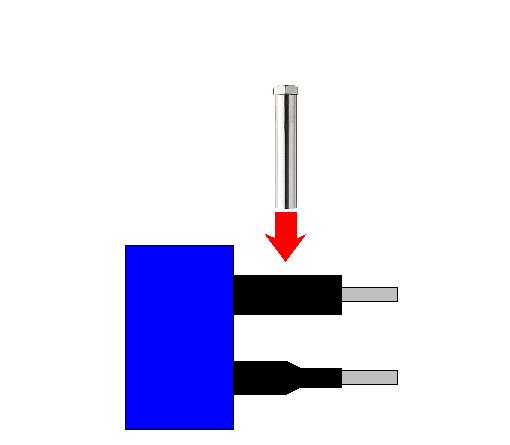

Read More »No.9 Thermal caulking / grilled fit

[ Problem Point ] When baking was put in by gas,control of a rubber gas hose was serious. [ ⇒Kaizen Point ] It was changed so that baking might be put in by the Air Blow Heater. So a process ...

Read More »No.8 Heat sealing of paper carton

[ Problem Point ] When it was heated, paper caught fire,and we were in trouble about gas. [ ⇒Kaizen Point ] It was heated, and did heat sealing of a spot by the Air Blow Heater It could be worked ...

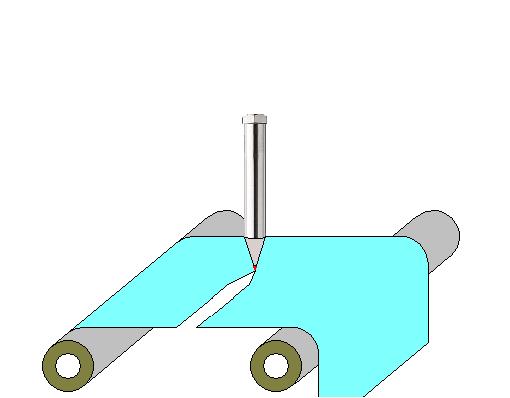

Read More »No.7 Torch of the resin weld

[ Problem Point ] There was nothing good as a torch for resin welds,and we were in trouble. [ ⇒Kaizen Point ] Spot was heated by the Air Blow Heater and resin was welded. The finish could heat a pinpoint, ...

Read More »No.6 Remelting of the hot glue

[ Problem Point ] Over time the molten adhesive is applied to the box,the box was also open to poor adhesion. [ ⇒Kaizen Point ] The remelting of the hot-spot heating with the Air Blow Heater And good adhesion, the ...

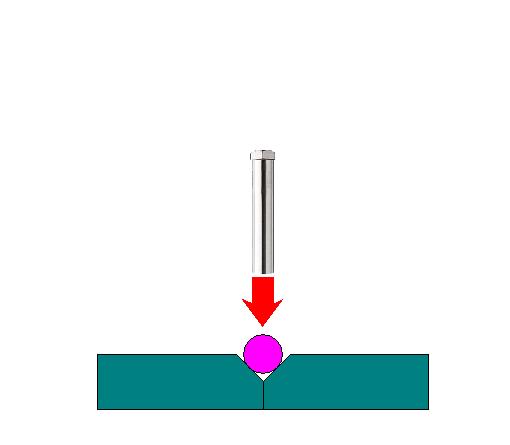

Read More »No.5 Heat-shrinkable tubing

[ Problem Point ] We were in trouble about a dryer for industry because devices burned out because the area was too wide. [ ⇒Kaizen Point ] We heated only a lead by a small spot by the Air Blow ...

Read More »No.4 Film shrink

[ Problem Point ] Dryer for industry was being used. Without being made,accurate temperature control would be a problem. [ ⇒Kaizen Point ] We can control the accurate temperature by the Air Blow Heater, so wrinkles and a spot of ...

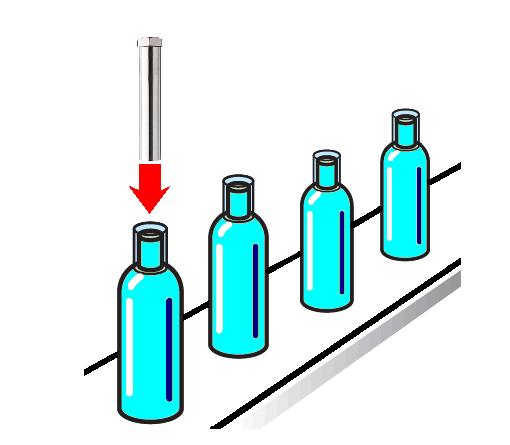

Read More »No.3 Cap Seal

[ Problem Point ] Dryer for industry was being used. Without being made, accurate temperature control would be a problem. [ ⇒Kaizen Point ] We can control the accurate temperature by the Air Blow Heater, so wrinkles and a spot ...

Read More »No.2 Processing of chocolate

[ Problem Point ] There were no tools in which chocolate is dissolved by the pinpoint, and We were in trouble. [ ⇒Kaizen Point ] A pen heater was made using an extraordinarily the Air Blow Heater We could give ...

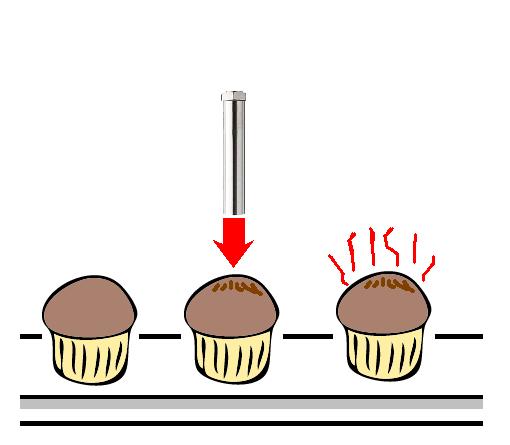

Read More »No.1 Coloring of the cake baking

[ Problem Point ] When the baking color was put,the smell of the gas shifted,so we were in trouble about gas. [ ⇒Kaizen Point ] The spot was heated by the Air Blow Heater and the baking color was put.The ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop