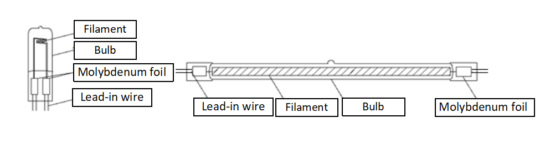

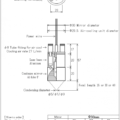

Like incandescent lamps, halogen lamps need to have a sealed structure that prevents the enclosed gas from leaking to the outside. Also, in halogen lamps, the temperature of the valve must be 250 degrees or higher as a condition for causing a halogen cycle, so glass with a high heat resistant temperature such as quartz glass is used for the valve. Quartz glass has a coefficient of thermal expansion that is more than 10 times smaller than that of soda glass used for general light bulbs. Silica glass uses an introduction line of an alloy of iron and nickel called Jumet line, and since the coefficient of thermal expansion is relatively close, it can be sealed as it is. Since quartz glass is used in halogen lamps, in order to match the coefficient of thermal expansion, instead of sealing the linear introduction line with glass, a metal leaf called molybdenum, which is 20 to 30 μm (0.02 mm to 0.03 mm), is ultra-thin. Is used. If the molybdenum foil is thicker than this, cracks will occur in the quartz glass due to the difference in the coefficient of thermal expansion and the airtightness will not be maintained. Become.

The introduction line is made of materials using molybdenum and tungsten.

Unlike the molybdenum foil in the sealing part, this introduction line does not match the coefficient of thermal expansion with quartz glass, so it has a pinch seal, but it is not strictly in close contact. Only the part of the molybdenum foil is in close contact with the quartz glass, which maintains the airtight structure. And, the introduction line that goes out from the sealing part of the bulb is always exposed to the outside air, and when it is lit, it is in a high temperature atmosphere. In a hot atmosphere. The introduction line gradually oxidizes and finally progresses to the molybdenum foil at the sealing part. As the oxidation progresses, the sealing part is damaged due to the temperature rise and thermal stress caused by the increase in resistance value.

One way to prevent this damage is to apply an antioxidant treatment to the molybdenum foil itself. The first is to implant a substance consisting of chromium, Aluminium, silicon, titanium, tantalum, palladium, etc. into the molybdenum foil itself or the outer line itself by ion implantation. The second method is to coat the plane of the molybdenum foil with an oxidation-resistant film made of silicon oxide.

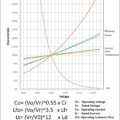

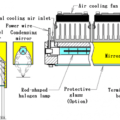

Oxidation of molybdenum foil occurs in a high temperature atmosphere, and gradually begins to oxidize at 200℃ or higher in the air. As an anti-oxidation measure, it is effective to forcibly cool the seal part with compressed air and to install a heat sink to dissipate heat from the seal part. At our company, as accelerated heat dissipation of the heat sink, the Aluminium base of the Halogen Point Heater is filled with metal oxide powder with good thermal conductivity, and the heat of the lamp encapsulation part is transferred with high efficiency and radiated from the Aluminium base. increase.

Home / Halogen Point Heater / Basic knowledge of Halogen heater / 4.Knowledge of Halogen Lamps / 4-6.About the seal of halogen lamps

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop