INDEX

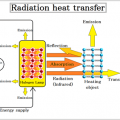

할로겐 히터는 공급한 전기를 할로겐 램프가 광선으로 변환하고 집광경에 의해 빛을 집중시켜 고온 가열하는 히터입니다.

할로겐 램프의 파장 분포의 대부분은 500nm~2500nm 영역의 가시광선~근적외선 영역입니다.

근적외선 영역 중 피크 파장은 약 900nm~1000nm입니다.

그 때문에, 가열 대상물의 흡수율이 근적외선 영역의 분광 분포에 가까울수록 가열 효율이 좋다.

할로겐 히터의 특징

(1) 에너지 교환률이 높음

전기 에너지를 광 에너지로 교환하는 비율은 90% 이상. 전기를 사용한 가열에서는 가열 효율이 매우 좋다.

할로겐 램프는 텅스텐 제 필라멘트에서 전달되는 전기를 빛으로 변환합니다.

할로겐 히터는 램프에서 방출되는 빛(가시광선 ~ 근적외선 영역)을 이용하고 있습니다.

증발한 금속 입자를 할로겐 가스로 환원하므로 수명이 길어져 공업용으로 사용되고 있습니다.

할로겐 램프의 변환 효율은 가시광선이 약 10%, 적외선이 약 80%, 그 밖에 극히 작지만 자외선도 방사하고 있습니다.

가시광선이나 자외선도 전자파이므로 물체를 가열하는 에너지는 있습니다.

전체 전자파로의 변환 효율은 약 90%로 매우 효율이 좋은 가열 수단입니다.

가열 대상물에 집중시키는 효율은 집광경의 곡률에 따라 달라집니다.

단초점의 집광경일수록 집광경의 이용률이 높아지고, 집광 효율도 좋아집니다.

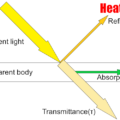

조사한 전자파가 흡수되어 열을 대체합니다만, 가열 대상물의 흡수율이나 색, 표면 상태에 따라 흡수량=온도는 크게 달라집니다.

그 때문에, 광(전자파)의 90%를 구성하는 적외선의 흡수율을 파악하는 것이 중요합니다.

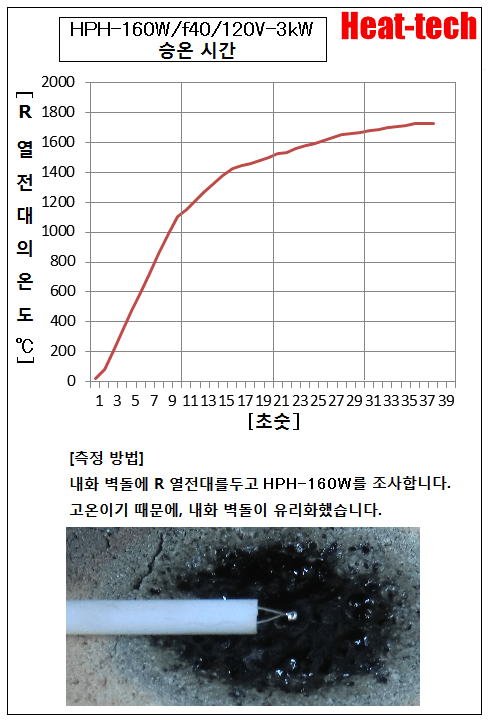

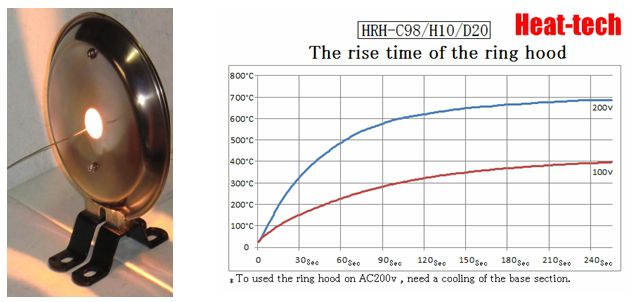

(2) 히터본체의 상승 시간이 매우 빠름

히터가 순식간에 일어나기 때문에 공회전 시간이 절약되고 경제적입니다.

당사 최상위 기기 HPH160의 경우 최고 온도의 70% 출력까지 약 12초에 도달합니다.

(3) 전압을 항상 변경할 수 있으며 PID 제어에 적합합니다.

가열 환경에 따라 온도를 변경하려면 할로겐 히터의 전압을 변경하여 온도를 제어할 수 있습니다.

정격 전압 이하로 사용하면 수명을 조정할 수 있습니다.

(4) 유리 너머의 가열이 가능하고 클린 룸 내나 진공 챔버 내도 대응할 수 있습니다.

램프 본체가 석영 유리로 제조되고 있기 때문에 유리 너머로 사용이 가능합니다.

단, 클린룸에서 사용하는 경우에는 할로겐 히터를 ‘클린룸 사양’으로 해야 합니다.

(5) 집광경에 의해 조사한 빛을 집중시킬 수 있습니다.

할로겐 히터의 종류에 따라 점·원 가열이나 선·면 가열 등 집중 가열할 수 있습니다.

(6) 금속에 대한 가열에서 비금속의 가열까지 광범위한 가열이 가능합니다.

할로겐 히터는 근적외선 영역에서의 가열에 적합하며 폭넓은 분야에서 활용, 가열이 가능합니다.

(7) 접착제나 도료 등 반투명한 소재는 표면의 가열 이외에 내부도 가열할 수 있습니다.

(8) 다른 가열 방법에 비해 안전합니다.

트러블시 히터 강온이 빠르기 때문에 피가열물의 발화의 위험성을 경감할 수 있습니다.

크세논 램프는 자외선 영역의 빛을 조사도 포함되어 있기 때문에, 육안으로 빛의 확인은 적합하지 않습니다.

또한 램프의 종류에 따라 다르지만 시동시 순간적으로 약 3만V의 고전압을 사용하므로 취급에 주의가 필요합니다.

레이저광의 취급에는 엄격한 기준이 있어, 안전 기준도 다른 가열 방식과는 굉장히 다릅니다.

분류에 따라 눈이나 피부에 심각한 손상을 줄 수 있습니다.

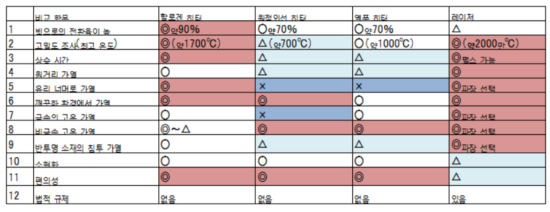

할로겐 히터를 다른 가열 방식과 비교한 표를 아래에 나타냅니다.

* 할로겐 램프의 빛의 파장은 약 1μm를 피크로하는 0.4 – 2.5μm 영역 (가시 광선-적외선 영역)입니다.

* 반투명 체 (피부와 페인트와 접착제 등)는 비교적 내부까지 들어가 내부에서도 가열된다.

* 금속에 대한 흡수율이 원적 외광보다 좋고, 비금속에 관하서서는 좋지 않은 물건도 차이가 많이 나옵니다.

HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵