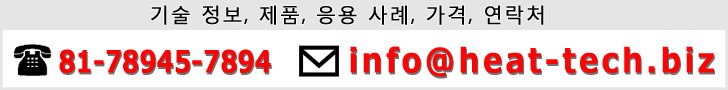

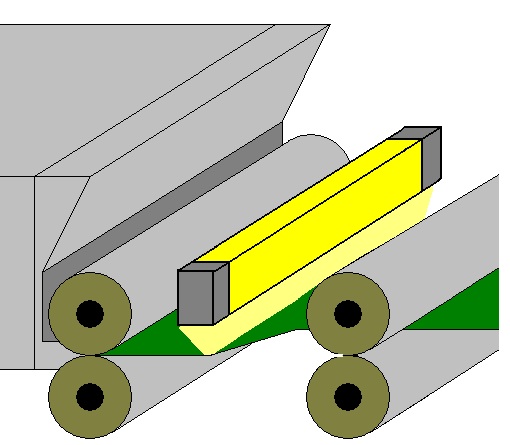

[ 문제점 ] 설치 공간이 좁고,긴 소형 강력한 히터가 없어 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터 아래로 끼고 예열했다 판 두께에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 지금까지 두 30 분 걸려 있던 유휴 ...

Read More »제 14 호 수축 가공

[ 문제점 ] 온도 관리의 좋은 방법이 없어서 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터 건조한 수축 필름의 두께에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 가능했다. ...

Read More »제 14 호 수지 용접

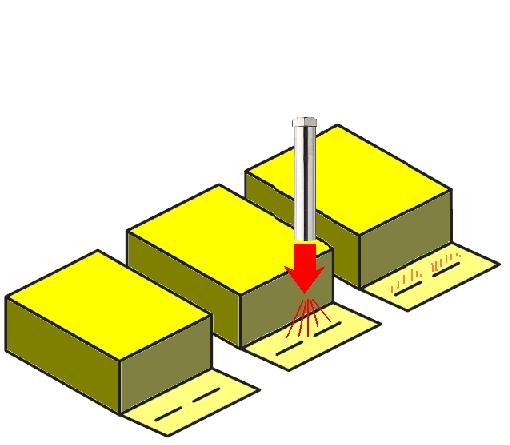

[ 문제점 ] 무산소로 용접하는 좋은 방법이 없어 곤란했던 [ 개선의 포인트 ] 소 스폿의 할로겐 스포트 히터 수지 용접했다. 질소 분위기에서 쉽게 용접했다. 접합 품위가 향상되었다.

Read More »제 13 호 플라스틱 재료의 가열 경화

[ 문제점 ] 온도 관리의 좋은 방법이 없어서 곤란해하고 있던. [ 개선의 포인트 ] 할로겐 라인 히터 건조한 판 두께에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 가능했다. ...

Read More »제 13 호 다층 막 폴리머 필름의 성형

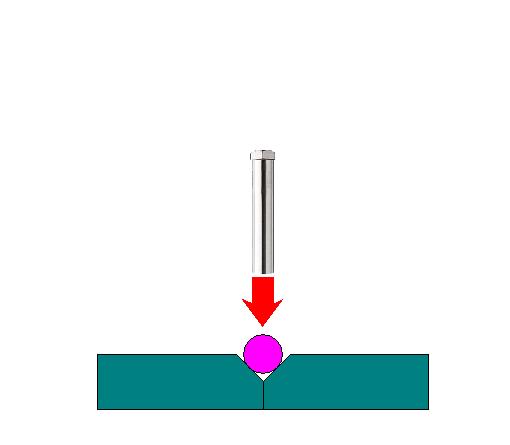

[ 문제점 ] 에 금형을 관통 폴리머 필름이 가열있는 히터가 없었다 [ 개선의 포인트 ] 할로겐 스포트 히터를 사용하여 스포트 타입이므로, 위의 형식을 통과 노린 위치를 핀 포인트로 가열 하였다. 또한 단시간에 승온하기 때문에 생산 택트 타임이 올랐다.

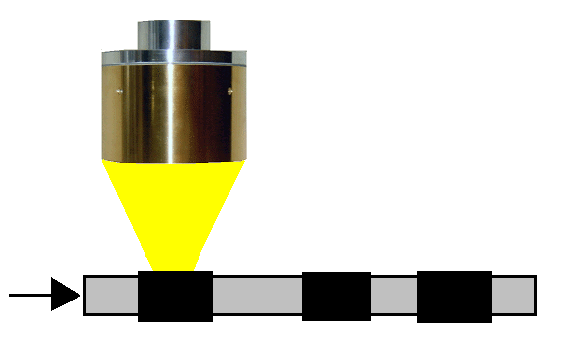

Read More »제 12 호 열 수축 튜브의 수축

[ 문제점 ] 열 수축 튜브의 내열성과 전선 피복의 내열성이 달리 전선이 타서 무력했다 [ 개선의 포인트 ] 할로겐 포인트 히터 가열했다. 승온 · 강 온 시간이 짧고 온도 제어가 간단하기 때문에 수축이 잘 갔다. 포인트 가열하기 때문에 전선의 열 ...

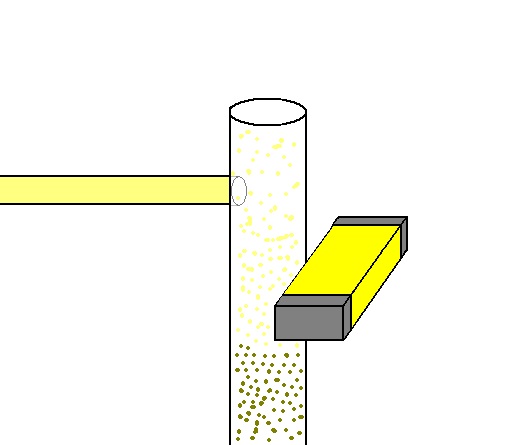

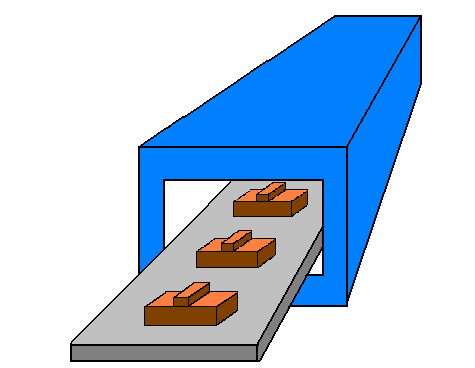

Read More »제 11 호 분말의 건조

[ 문제점 ] 좋은 건조 방법이 없어 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터 건조한 적외선 석영 유리를 투과하기 때문에 자연 낙하 중에 건조시킬 수 있었다. 휘발성 성분은 유리관 상부에서 배출했다. 비접촉식이므로 안전성과 청정성을 확보할 수 있었다.

Read More »제 1 호 소형 건조로

[ 문제점 ] 소형 건조로 좋은 방법이 없어 곤란했던 [ 개선의 포인트 ] 순간 온도 상승의 원적외선 히터 건조했다. 단시간에 건조로이 온도 상승하므로 가동 시간이 증가했다. 돌발적인 인터럽트 작업에도 유연하게 대응할 수있게되었다.

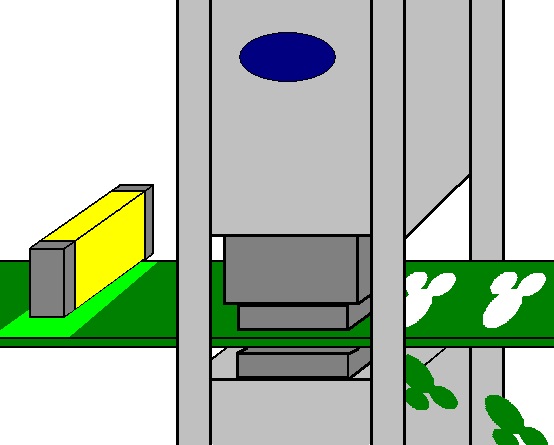

Read More »제 10 호 수지 재단시 열원

[ 문제점 ] 판 균열이 발생 무력했다 [ 개선의 포인트 ] 할로겐 라인 히터로 예열했다 판 두께에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 가능했다. 지금까지 두 30 ...

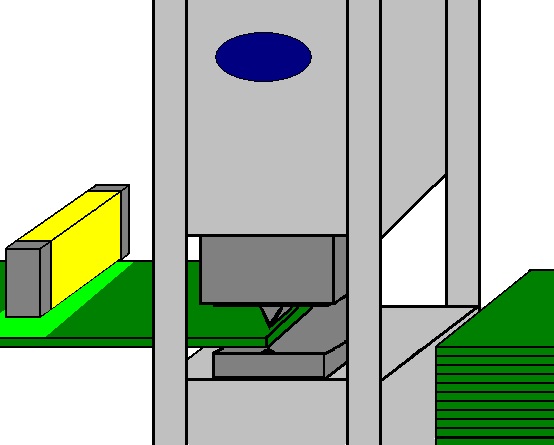

Read More »제 9 호 수지 보도 예열 공정

[ 문제점 ] 상승의 빠른 가열 방법이 없어 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터로 예열했다 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 가능했다. 지금까지 두 30 분 걸려 있던 유휴 시간은 제로가되었다. 또한 전기 ...

Read More »제 8 호 수지 펠렛 건조

[ 문제점 ] 온도 관리의 좋은 방법이 없어서 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터 건조한 수지 (레진)의 종류에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 ...

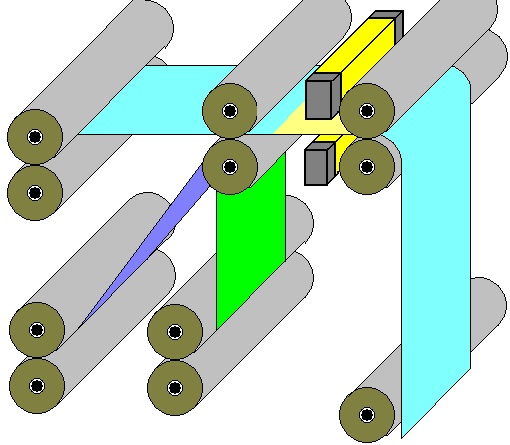

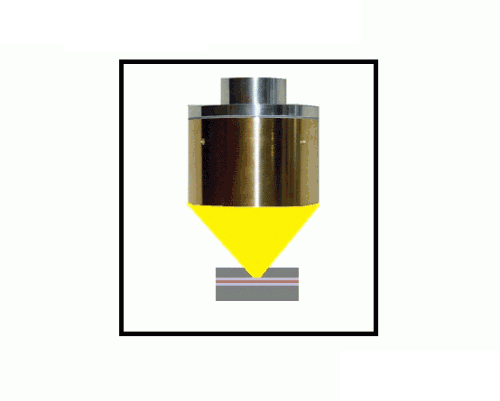

Read More »제 8 호 인쇄 건조

[ 문제점 ] 지점으로 건조 열원으로 좋은 방법이 없어서 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 포인트 히터로 15 초 온도를 올렸다. 대상이 명확하기 때문에 히터 데미지를 방지했다.

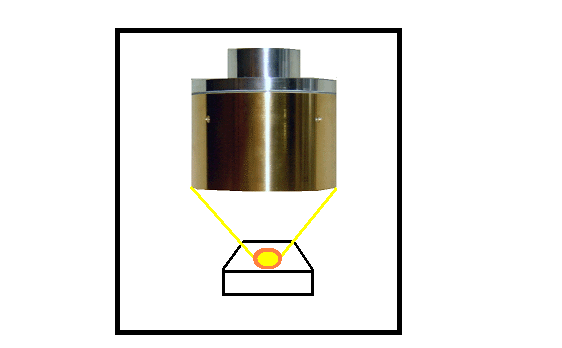

Read More »제 7 호 진공 챔버 내의 시료 가열

[ 문제점 ] 진공에서 시료 가열 열원으로 좋은 방법이 없어서 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 포인트 히터로 1400 ℃에 순간적으로 온도를 올렸다. 소재의 변화가 뚜렷이 나타나고있는

Read More »제 6 호 할로겐 라인 히터에서 도료의 건조

[ 문제점 ] 온도 관리의 좋은 방법이 없어서 곤란해하고 있던 [ 개선의 포인트 ] 할로겐 라인 히터 건조한 에 따라 온도를 바꿀 수 있으므로, 제품 품위가 향상 5 초 최고 온도까지 승온하기 때문에 운전 개시 직후부터 작업이 가능했다. 지금까지 ...

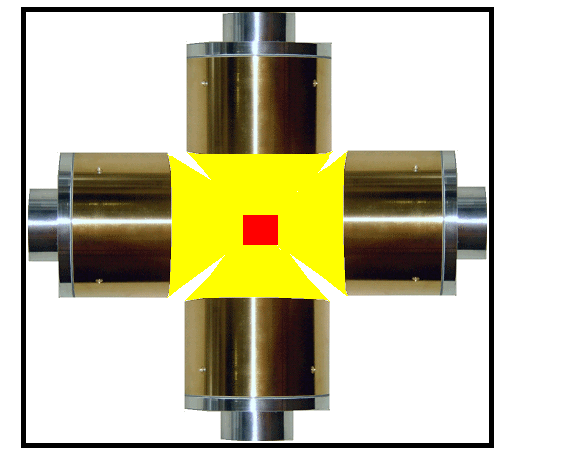

Read More »제 6 호 열 발전 시험 시스템의 열원

[ 문제점 ] 열 발전 시험 시스템의 열원으로 좋은 방법이 없어서 곤란해하고 있던 [ ⇒개선의 포인트 ] 열 발전 모듈은 표면을 가열 뒷면을 냉각하여 발전한다. 할로겐 히터 포인트 최고 1000 ℃까지 순간적으로 온도를 올릴 수 있었다. 컨트롤러는 온도 제어 출력 ...

Read More »제 7 호 수지 용접 토치

[ 문제점 ] 수지 용접 용 토치으로 좋은 것이없고 무력했다. [ 개선의 포인트 ] 열풍 히터에서 스포트 가열하여 수지 용접했다. 핀 포인트로 가열 할 수 있고, 마무리가 깨끗 해졌다.

Read More »제 5 호 빛 사이펀 테이블

[ 문제점 ] 가스 배관 수 없어 때문에 무력했다 [ ⇒개선의 포인트 ] 할로겐 포인트 히터 에서 사이펀을 가열했다. 가스 배관없이 커피를 추출할 수 있으므로, 점포 레이아웃 디자인이 자유롭게되었다. 또한 유리를 투과하여 직접 물을 데우는 때문에 유리 관리가 쉽게되었다. 환상적인 ...

Read More »제 6 호 핫멜트의 재용 화

[ 문제점 ] 핫멜트를 도포 한 후 시간이지나 접착이 나빠서 포장 상자 때도 있었다. [ 개선의 포인트 ] 열풍 히터에서 스포트 가열 핫멜트의 재용 화했다. 접착이 좋아져, 클레임이 없어졌다.

Read More »제 5 호 열수축 튜브의 가열

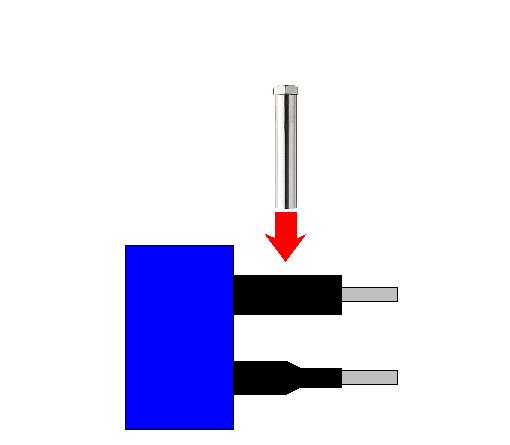

[ 문제점 ] 산업용 도라이아는 범위가 너무 넓은 소자가 소손 곤란했다. [ 개선의 포인트 ] 열풍 히터에서 리드 만 소 스폿에서 가열하여 수축시켰다. 소자를 가열하지 않기 때문에 신뢰성이 향상되었다.

Read More »제 4 호 필름 수축

[ 문제점 ] 산업용 도라이아를 사용했다 미세한 온도 관리 못하고 무력했다. [ 개선의 포인트 ] 열풍 히터에서 정확한 온도 관리가 가능하기 때문에 씰의 주름이나 얼룩이 없어졌다.

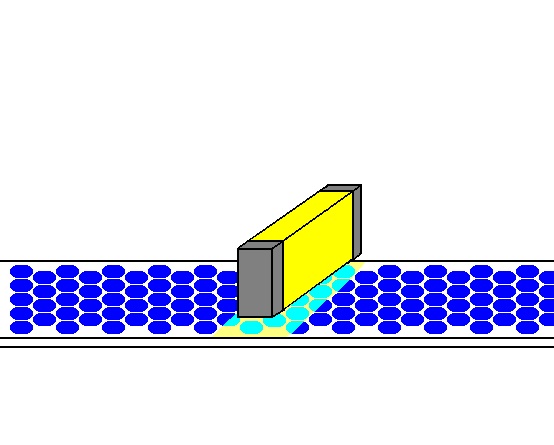

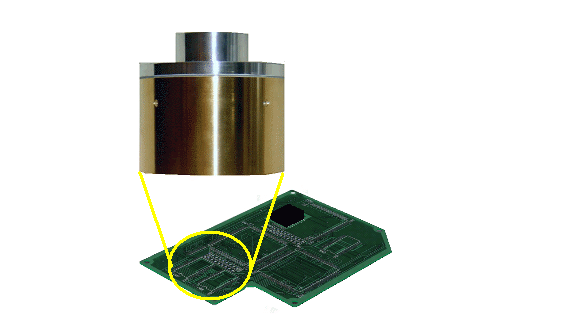

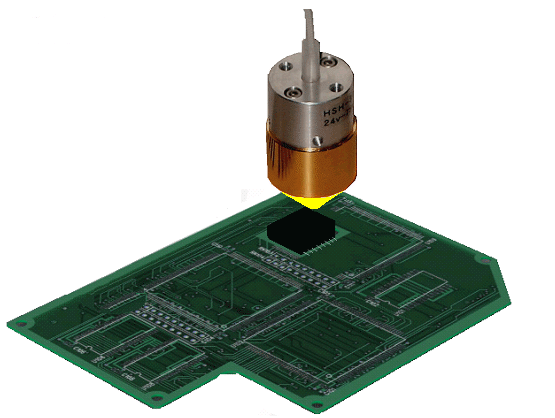

Read More »제 2 호 PCB의 예열

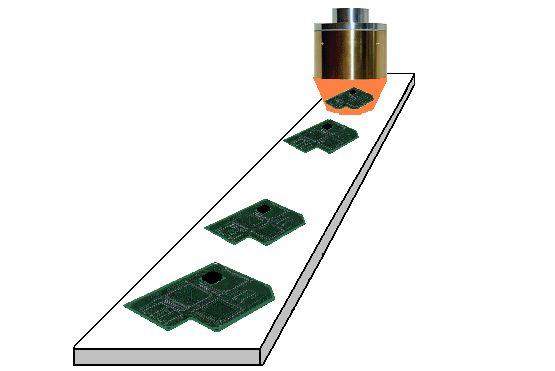

[ 문제점 ] 프린트 기판의 예열 좋은 방법이 없어서 곤란해하고 있던. [ ⇒개선의 포인트 ] 할로겐 포인트 히터를 아웃 포커스를 예열했다. 승강온 시간이 짧고 온도 제어가 간단하기 때문에 납땜이 잘 갔다. 비접 촉으로 가열하기 때문에 핸들링이 쉽게되었다.

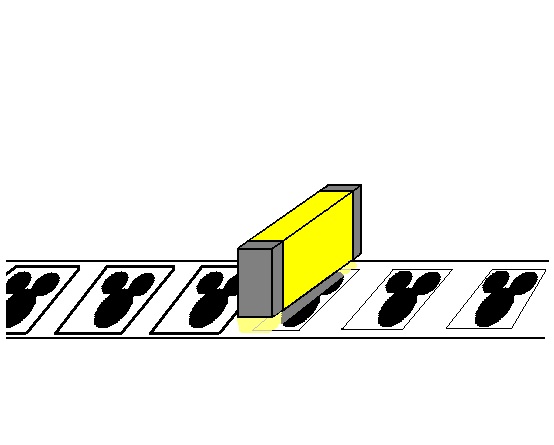

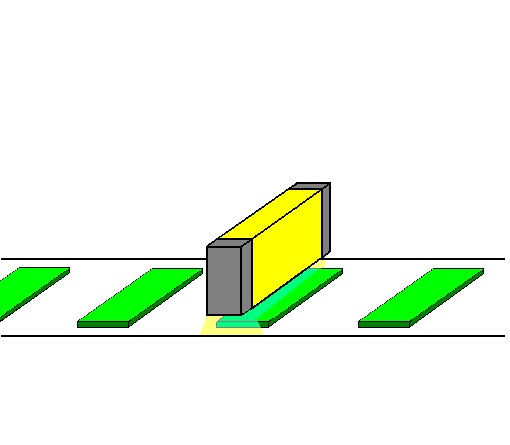

Read More »제 1 호 PCB의 납땜

[ 문제점 ] 무연 납땜의 좋은 방법이 없어서 곤란해하고 있던 [ ⇒개선의 포인트 ] 작은 포인트 할로겐 포인트 히터 납땜했다. 승강온 시간이 짧고 온도 제어가 간단하기 때문에 납땜이 잘 갔다. 포인트 가열이므로 다른 부품에 열 스트레스를 최소한으로 억제되었다. 또한 비접촉식이므로 ...

Read More » HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵