INDEX

超級工程塑料(以下簡稱SEP)是一種增強工程塑料功能的樹脂。

有些也被稱為“特殊工程塑料”。

SEP是一種耐熱的第三代合成樹脂,可提高耐熱塑料的固有性能。

高耐熱性改善了運動部件中的摩擦耐熱性,並且還提高了整體機械強度。

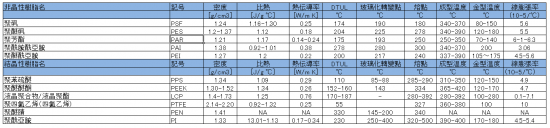

一般性能為:DTUL為150℃或更高,拉伸強度為500kgf / cm2或更高,彎曲模量為25000kg / cm2或更高。

與金屬零件比較

<<優點>>

材料本身可以減輕產品的重量

複雜的形狀可以以低成本精確加工和製造

足夠的強度,使設備小型化,因為可以容易地製造內部和外部的複雜形狀

由於可以集成部件,因此可以減少部件數量並且可以降低成本

不生鏽

即使沒有油也具有出色的耐磨性

即使在塗漆時也不需要塗漆或固定

可用於3D打印機

<<弊點>>

部件強度在高溫下降低

零件的強度可能會在低溫下降低,或者

由於硬度低於金屬,因此耐磨性較低

在暴露於陽光的環境中,它會被紫外線降解

即使暴露在溶劑,化學品和氣體中也可能會變脆

許多分子結構含有許多苯環結構,這些結構在自然界中不存在,並且生物降解性差。

◇非晶性SEP

1.聚砜(PSF)

琥珀色透明樹脂。 優異的韌性,耐熱性和耐水解性,即使在高溫下也對酸,鹼和熱水穩定,但要注意有機溶劑。 優異的抗蠕變性,低溫特性,電氣特性,阻燃性和尺寸穩定性。 儘管由於吸濕而沒有物理性質的損失,但它會產生氣泡和銀,因此在模塑之前需要充分乾燥。

2.聚醚砜(PES)

琥珀色透明樹脂。 優異的耐熱性,耐水解性,阻燃性和抗蠕變性。 尺寸穩定性好。 耐化學性良好,抗應力開裂性優異,但有機溶劑需要注意。

3.多芳基化合物(PAR)

透明樹脂。 目前,有許多合金復合材料。 PAR / PC,PAR / PET,PAR / PA和PAR /氟樹脂等合金在市場上出售。 其特徵在於耐熱性(Tg:195),UV阻隔性,抗衝擊性,表面硬度,抗蠕變性和回复彎曲彈性。 注意熱水和蒸汽,因為它們的分子中有酯鍵。 還必須注意有機溶劑。

4.聚酰胺酰亞胺(PAI)

優異的耐熱性(連續使用溫度250),耐衝擊性,耐疲勞性,阻燃性,耐磨性,耐化學性和耐應力開裂性。 良好的電氣特性。

5.聚醚酰亞胺(PEI)

琥珀色透明樹脂。 優異的耐熱性,機械性能,阻燃性和電性能。 注意有機溶劑。

◇結晶性SEP

1.聚苯硫醚(PPS)

非常高的耐熱性(負載撓曲溫度260或更高)。優異的機械強度,剛性,阻燃性,電氣特性,尺寸穩定性和抗蠕變性。耐化學性特別優異,並且除了熱濃硝酸之外,它不受大多數酸,鹼和有機溶劑的侵蝕。耐熱水性極佳。由於傾向於出現填料的性質,因此開發了許多具有諸如滑動性,粘合性,導電性,超精密成形性,高導熱性和密封性等性能的化合物。在超級工程塑料中,由於其優異的性價比,使用量穩步增加。儘管存在韌性低的問題,但是容易產生毛刺,並且分子結構含有硫,模具的腐蝕和磨損很大,但是最近已經開發出改進的等級。

2.聚醚醚酮(PEEK)

熱塑性樹脂中的最高耐熱性(連續操作溫度240,負載下的撓曲溫度300 / GF 30%)。阻燃性,低雜質電阻,耐熱水性,耐輻射性,耐化學性和耐疲勞性也非常好。成型溫度需要很高。

3.液晶聚合物/液晶聚酯(LCP)

熔融時表現出液晶性的樹脂。非常好的流動性。剛性,強度,成型性,吸水性低,尺寸穩定性優異。毛刺和水槽相對較少。按耐熱性等級分為1,2和3型。目前市場上使用最廣泛的類型是Type 2,其負載撓曲溫度為220至280。此外,根據分子結構,它分為全芳族體系和半芳族體系。全芳族體系具有高耐熱性,半芳族體系具有優異的薄壁流動性。問題是存在各向異性,粘附性差和焊接強度低。此外,應注意熱水和蒸汽,因為它們的分子中有酯鍵。通常,應該注意吹掃方法,因為它具有在高溫下容易粘附金屬的性質,並且即使在300或更高溫度下也沒有商業上可獲得的穩定的吹掃劑。

4.氟樹脂

分子中含氟樹脂的通稱(PTFE,PFA,FEP,E / TFE,PVDF等)。耐熱性,耐寒性,耐化學性,耐熱水性,耐候性極佳。優異的非粘性,低摩擦和高頻特性。

5.聚醚腈(PEN)

熱塑性樹脂中的最高耐熱性(連續操作溫度230,負載撓曲溫度330 / GF 30%)。 其強度約為通用工程塑料的兩倍,其阻燃性,低雜質抗性,耐熱水性,耐化學性,抗疲勞性,抗蠕變性和滑動性也非常好。 為了模塑,可以使用傳統的工程塑料兼容注塑機。昂貴。

6.聚酰亞胺(PI)

在有機聚合物中,耐熱性最高(連續使用溫度250或更高)。 優異的阻燃性,機械強度,耐磨性,抗蠕變性,耐輻射性和尺寸穩定性。