INDEX

In temperature measurement, one of the factors that cause measurement errors is temperature distribution variability. Temperature does not always spread uniformly; it significantly changes depending on the material of the measurement target, surrounding environment, and heat transfer methods (conduction, convection, and radiation).

If temperature measurements are conducted without considering this variability, different temperature values may be obtained depending on the measurement location, which may lead to incorrect temperature evaluations.

This chapter provides a detailed explanation of the causes of temperature distribution variability and specific countermeasures to minimize measurement errors.

4.1 What is Temperature Distribution Variability?

Temperature distribution variability refers to the phenomenon where the temperature is not uniform across the entire measurement target, resulting in different temperature readings depending on the measurement location. This variability occurs due to the following factors:

1. Non-uniform Heating and Cooling Equipment

Heaters and cooling devices do not always distribute heat or cold air evenly, leading to a temperature gradient in the heated or cooled object.

2. Differences in Thermal Conductivity of Materials

Materials with high thermal conductivity, such as aluminum, transfer heat quickly, while materials with low thermal conductivity, such as plastic, slow down heat transfer. This makes it difficult to achieve a uniform temperature distribution.

3. Influence of Air and Liquid Convection

In indoor spaces or within liquids, convection occurs as warm air or liquid rises while cooler parts sink, creating temperature differences depending on the measurement position.

4. Effects of Radiant Heat

Heat radiated from an object’s surface can cause differences in surface and internal temperatures. This effect is especially pronounced in high-temperature environments.

Since these factors interact in complex ways, they can introduce measurement errors. Understanding temperature distribution variability and selecting appropriate measurement methods is crucial to improving measurement accuracy.

4.2 Causes of Measurement Errors Due to Temperature Distribution Variability and Countermeasures

4.2.1 Effects of Thermal Conduction and Countermeasures

Thermal conduction is the process of heat transfer within a material. However, not all materials conduct heat at the same rate, leading to differences in how temperature spreads.

Causes:

1. High Thermal Conductivity Materials (e.g., Copper, Aluminum)

These materials distribute heat more evenly, but if the object has a large volume, a temperature difference may still exist between the center and edges.

Example: When heating one side of an aluminum plate, the center and edges may experience different temperatures.

2. Low Thermal Conductivity Materials (e.g., Plastic, Ceramic, Insulating Materials)

Even if the surface temperature changes, the heat takes time to penetrate the interior.

Example: A thick plastic sheet heated from one side will experience a quick temperature rise on the surface, while the back side remains relatively cool.

Countermeasures:

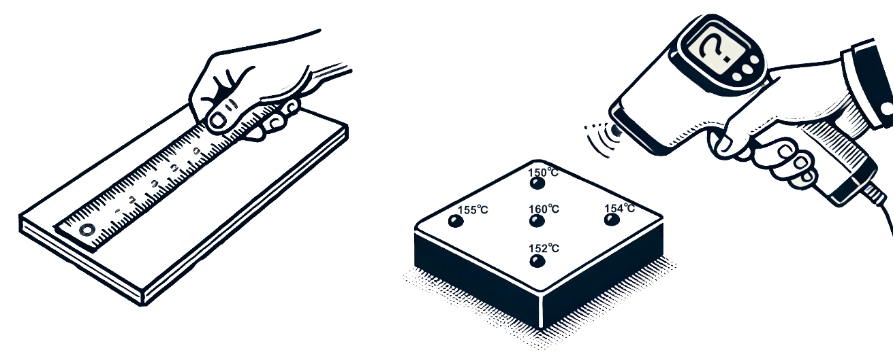

1. Measure at Multiple Locations and Take the Average

If the temperature is not uniform, measuring at multiple points and averaging the readings will provide a more accurate temperature estimate.

2. Consider Differences in Thermal Conductivity When Measuring Temperature

For materials with low thermal conductivity, such as stainless steel, wait for an extended period until the internal temperature stabilizes before measuring.

3. Insert the Temperature Sensor into the Interior of the Measurement Target

Measuring both surface and internal temperatures helps account for the effects of thermal conduction.

4.2.2 Effects of Thermal Convection and Countermeasures

In gases and liquids, heat is primarily transferred through convection. This occurs as warmed fluid (air or water) expands, becomes lighter, and rises while cooler fluid sinks.

Causes:

1. Air Convection

In indoor environments, warm air rises while cool air descends, creating temperature differences between the ceiling and the floor.

Example: In a sauna, the temperature near the ceiling is significantly higher than that near the floor.

2. Water Convection

When heating liquid, the warm portions rise while cooler portions sink, creating convection.

If the stirring is insufficient, temperature variations may persist within the liquid.

Example: In a cooking pot, the bottom layer of water heats up first, but if not stirred, the top layer remains cooler.

Countermeasures:

1. Use Fans or Stirring Devices to Equalize Temperature

In air, use fans to circulate airflow and reduce temperature inconsistencies.

In liquids, use stirring devices to ensure uniform temperature distribution.

2. Wait for Temperature to Stabilize Before Measurement

Avoid measuring immediately after air conditioning or heating starts; wait until room temperature stabilizes.

For liquids, stir well after heating to ensure an even temperature before measurement.

4.2.3 Effects of Radiant Heat and Countermeasures

Radiant heat is the transfer of heat via infrared radiation. The accuracy of temperature measurements can be affected by differences in emissivity (the ability of a material to emit or absorb infrared radiation).

Causes:

1. High-Emissivity Materials (e.g., Brick, Wood, Paper)

These materials absorb heat efficiently, causing significant temperature variations.

Example: A black car absorbs more infrared radiation from sunlight than a white car, making its surface hotter.

2. Low-Emissivity Materials (e.g., Polished Metal Surfaces)

These materials reflect heat, often leading to surface temperature readings lower than the actual temperature.

Example: When heated under the same heat source, a wooden surface will register a higher temperature than an aluminum surface.

Countermeasures:

1. Apply Emissivity Correction

When using an infrared thermometer, adjust the emissivity setting correctly to ensure accurate readings.

If the emissivity is unknown, use a contact-based temperature sensor (such as a thermocouple) to measure the actual temperature and estimate the correct emissivity setting.

2. Standardize the Surface Properties of the Measurement Target

Apply high-emissivity coatings, such as blackbody paint, to create uniform emissivity and reduce measurement errors.

3. Use Infrared Thermometers at the Appropriate Angle

Measure from an angle that minimizes reflected infrared radiation to improve accuracy.

4.3 Summary

If temperature distribution variability is not considered, significant measurement errors can occur. Therefore, it is essential to understand the effects of thermal conduction, convection, and radiation and adopt appropriate measurement techniques.

By selecting the appropriate measurement methods, more accurate and reliable temperature measurements can be achieved.