[ Problem Point ]

For lack of heat resistance, splice unsuccessful.

[ Kaizen Point ]

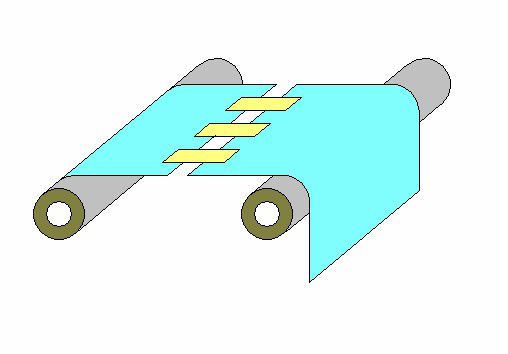

It was spliced using the Toughtape. The shape was stable by 260 ℃ of resistance to distortion at high temperatures, so splice work became smooth, and working hours could be reduced.