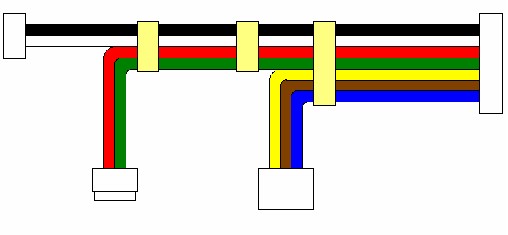

[ Problem Point ]

Degradation would be a problem early for a high fever near the engine.

[ Kaizen Point ]

It banded together using the Toughtape corresponding to 260 ℃ of high fever. Since after heating has stable adhesive power, it is improvement in reliability