[ 문제점 ] 수지봉의 기계적 보호 대책에 사용하는 수축용의 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 수지봉의 기계적 보호 대책이 되었다.

Read More »제6호 유리관 방수 보호

[ 문제점 ] 유리관의 균열 방수 보호 대책에 사용하는 수축용의 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 유리관의 균열 방수 보호 대책이 되었다.

Read More »제5호 PVC 파이프의 방수 보호

[ 문제점 ] PVC 파이프의 방수 보호 대책에 사용하는 수축 용 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. PVC 파이프의 방수 보호 대책이 되었다.

Read More »제4호 알루미늄 파이프의 방식 보호

[ 문제점 ] 알루미늄 파이프의 방식 대책에 사용하는 수축용 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 알루미늄 파이프의 부식 대책이 되었다.

Read More »제3호 스테인레스 스틸 파이프 장식

[ 문제점 ] 스테인레스 스틸 파이프 장식에 사용되는 수축 용 링 히터를 찾고있었습니다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 택트 타임의 단축이 되었다.

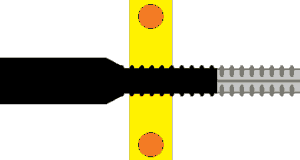

Read More »제2호 철근 방청 방식

[ 문제점 ] 철근 보호용 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 택트 타임의 단축이 되었다.

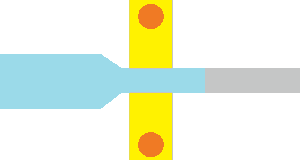

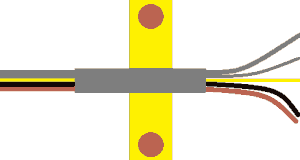

Read More »제1호 전선의 결속

[ 문제점 ] 와이어 하네스 용 링 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 링 히터 CFRH를 사용하여 흡수 파장이 적합하기 때문에, 열 수축 튜브가 즉시 수축되었다. 택트 타임의 단축이 되었다.

Read More »제11호 건조로의 열원

[ 문제점 ] 소형 고효율의 중적외선 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다.

Read More »제10호 유리 예열 처리

[ 문제점 ] 소형 원적외선 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 가열하였다. 흡수 파장이 적합하기 때문에, 유리는 즉시 승온되었다.

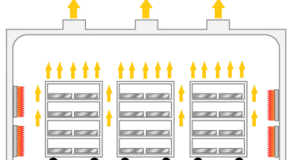

Read More »제9호 열 수축 터널의 열원

[ 문제점 ] 온도 관리하기 쉬운 저온 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 가열하였다. 흡수 파장이 적합하기 때문에, 수지는 즉시 수축되었다.

Read More »제8호 냉동 창고의 서리 제거

[ 문제점 ] 효율적인 제상 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 제상하였다. 흡수 파장이 얼음에 적합하기 때문에, 서리는 물없이 직접 승화되었다.

Read More »제7호 수산물 건조

[ 문제점 ] 숙성시키기 위해서, 온도 관리하기 쉬운 저온 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 수분은 즉시 증발하였다. 저온 히터이므로, 고온이 되지 않고 숙성 관리가 편해졌다.

Read More »제6호 김 건조

[ 문제점 ] 맛을 유지하기 위해 온도 관리하기 쉬운 저온 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 수분은 즉시 증발하였다. 저온 히터이므로, 고온이 되지 않고 구운 색 관리가 편해졌다. ...

Read More »제5호 수성 잉크 건조

[ 문제점 ] 무두질 대책을 위해 자외선이 포함되지 않은 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 자외선 성분이 없기 때문에 대책이 되었다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다.

Read More »제4호 수성 페인트 건조

[ 문제점 ] 무두질 대책을 위해 자외선이 포함되지 않은 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 자외선 성분이 없기 때문에 대책이 되었다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다.

Read More »제3호 자동차 페인트 건조

[ 문제점 ] 히트 데미지 대책을 위한 온도 관리하기 쉬운 저온 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다. 저온 히터이므로 히트 데미지 대책이 되었다.

Read More »제2호 PCB 세척 후 건조

[ 문제점 ] 히트 데미지 대책을 위한 온도 관리하기 쉬운 저온 히터를 찾고 있었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다. 저온 히터이므로 히트 데미지 대책이 되었다.

Read More »제1호 정밀 세척 후 300mm 실리콘 웨이퍼 건조

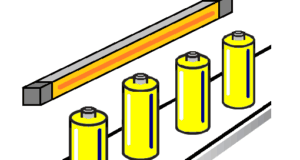

[ 문제점 ] 실리콘 웨이퍼상의 물방울을 빠르게 증발시키는 좋은 히터가 없었다. [ 개선의 포인트 ] 탄소 라인 히터 CFLH로 중적외선을 조사하여 건조시켰다. 흡수 파장이 적합하기 때문에, 물방울은 즉시 증발하였다. 택트 타임의 단축이 되었다.

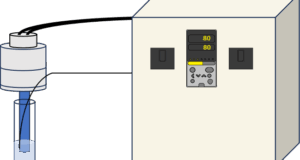

Read More »제 8 호 세포 배양액의 온도 관리

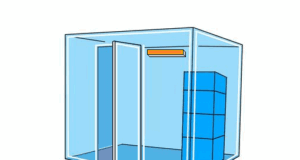

[ 문제점 ] 세포 배양액을 정밀하게 온도 관리하는 방법을 찾고 있었다. [ 개선의 포인트 ] 온도 제어가 가능하기 때문에, 설정하고 싶은 온도에서 안정된 가열을 할 수 있게 되었다.

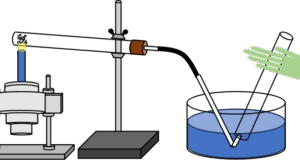

Read More »제 7 호 시약 가열

[ 문제점 ] 가스 관리의 번거로움이나 CO2 삭감을 목적으로, 시약의 가열로 가스 버너로부터의 치환을 검토하고 있었다. [ 개선의 포인트 ] 할로겐 유리 로드 히터로 대체하여 깨끗한 가열을 실현했다.

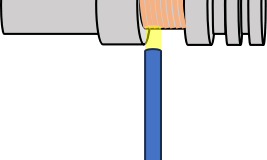

Read More »제 6 호 열 수축 튜브 수축

[ 문제점 ] 열 수축 튜브의 신축 공정을 자동화하는 방법을 찾고 있었다. [ 개선의 포인트 ] 할로겐 유리 막대 히터를 사용함으로써, 국소 가열이 가능하고, 다른 장소에 열의 영향을 최소화할 수 있었다.

Read More »제 5 호 권선 중 코일의 열 용착

[ 문제점 ] 극소의 선경의 코일의 권선중에 사용하는 히터를 찾고 있었다. [ 개선의 포인트 ] 좁은 장소에도 설치할 수 있어 국소 가열할 수 있어, 주위에 열의 영향이 적게 가열할 수 있게 되었다.

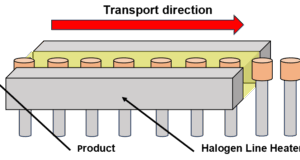

Read More »제86호 생산 라인에서 작은 부품의 어닐링

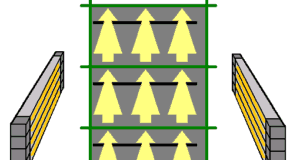

[ 문제점 ] 생산 라인에서 단시간에 고온 가열할 수 있는 방법을 찾고 있었다. [ 개선의 포인트 ] 할로겐 라인 히터를 대향시켜 가열함으로써, 가열 시간을 절약하고, 고온 가열이 실현되었다. 집광경을 이용한 적외선 가열에 의해 효율적인 가열이 가능하게 되었다.

Read More »제85호 우주 산업에서 재료의 내열 시험

[ 문제점 ] 우주선의 외각과 내장 재료의 내열성을 테스트하기 위한 가열 방법을 찾고 있었다. [ 개선의 포인트 ] 할로겐 히터의 가열에 의해 재료가 고온에 견딜 수 있는지를 확인할 수 있었다.

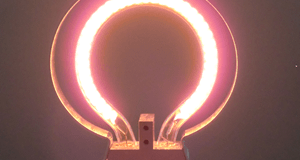

Read More »카본 링 히터 CFRH 시리즈

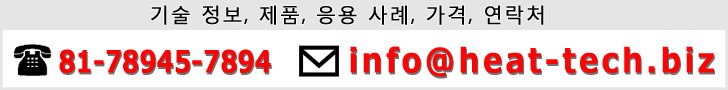

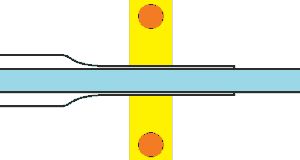

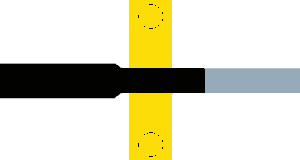

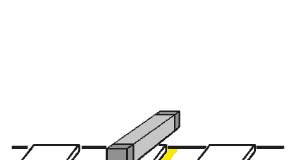

1.CFRH의 특징 1. 환상으로 모든 방향에서 조사. 환상으로 전방향에서 조사하기 때문에 사각이 없습니다. 2. 수지 가열에 최적 고분자 화합물 유래의 카본 섬유 발열체이므로, 수지의 가열이 잘 됩니다. 3. 상승이 빠르다 불과 2.7초에 80%, 8.5초에 100%에 도달. 4. 가열 방향이 자유 ...

Read More » HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵