이 동영상에서는 할로겐 라인 히터를 사용하여 적외선 고온 가열을 통해 폴리카보네이트 시트를 가열하는 과정을 촬영하였습니다. 폴리카보네이트는 높은 내열성과 투명성을 가진 수지로, 가열하면 유연성이 증가하여 성형 및 가공이 용이해집니다. 본 영상에서는 적외선 가열로 인한 온도 변화에 따라 폴리카보네이트가 연화되는 과정을 관찰하고 ...

Read More »적외선 고온 가열을 이용한 아연의 용해

이 동영상에서는 할로겐 라인 히터를 사용하여 적외선 고온 가열을 통해 아연을 비접촉 및 균일하게 가열하고 용해하는 과정을 촬영하였습니다. 아연은 419.5°C에서 용해되는 금속이며, 본 영상에서는 짧은 시간 내에 가열하여 용해가 시작되는 과정을 실시간으로 관찰하였습니다. 적외선 가열의 특성을 활용하여, 이 기술은 금속 ...

Read More »적외선 고온 가열을 이용한 주석의 용해

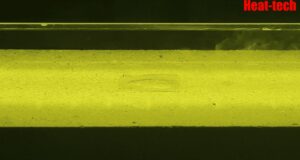

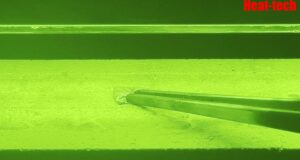

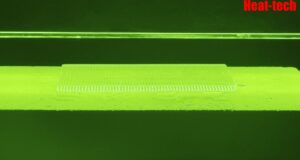

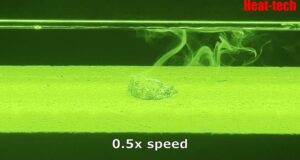

이 동영상에서는 할로겐 라인 히터를 사용하여 적외선 비접촉 가열로 주석을 용해하는 과정을 촬영하였습니다. 주석은 비교적 낮은 온도인 231.9°C에서 용해되는 금속이며, 본 실험에서는 약 10초 만에 용해가 시작됨을 확인할 수 있었습니다. 적외선 가열은 균일하고 신속한 가열이 가능하여 기존 가열 방식보다 효율성이 ...

Read More »적외선 고온 가열에 따른 유리의 열팽창 및 파손

이 영상에서는 적외선 고온 가열에 따른 유리의 열팽창 및 파손 과정을 소개합니다. 할로겐 라인 히터를 사용하여 유리를 고온으로 가열할 때 발생하는 열팽창과 그로 인해 발생하는 파손 과정을 촬영하였습니다. 이러한 지식은 유리 제조, 정밀 가공 및 내열 소재 연구 등 다양한 ...

Read More »적외선 가열을 이용한 마그네슘의 고온 용해 공정

이 동영상에서는 할로겐 라인 히터를 사용하여 마그네슘을 적외선으로 가열하고, 고온에서 용융 및 연소하는 과정을 촬영하였습니다. 가열 온도는 650℃ 이상에 도달하며, 마그네슘이 용융되고 연소하는 모습을 확인할 수 있습니다. 촬영 중에는 고온 가열로 인해 강한 발광이 발생하기 때문에 보호 안경을 착용하였습니다. 또한, ...

Read More »합성지 YUPO®의 물방울 건조

카본 라인 히터로 합성지 YUPO® 위의 물방울을 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »셀룰로오스 아세테이트 접착제의 건조 경화

카본 라인 히터로 셀룰로오스 아세테이트 접착제를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »PVA 폴리 비닐 알콜의 건조 경화

카본 라인 히터로 PVA 폴리 비닐 알코올을 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »전분 접착제의 건조 경화

카본 라인 히터로 전분 풀을 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »내화 퍼티의 건조 경화

카본 라인 히터로 내화 퍼티를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »스티렌 부타디엔 고무 접착제의 건조 경화

카본 라인 히터로 스티렌 부타디엔 고무 접착제를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »비닐 아세테이트 접착제의 건조 경화

카본 라인 히터로 비닐 아세테이트 접착제를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »클로로 브렌 고무 접착제의 건조 경화

카본 라인 히터로 클로로 블렌 고무 접착제를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »에폭시계 접착제의 건조 경화

카본 라인 히터로 에폭시계 접착제를 건조 경화하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »용암의 건조

카본 라인 히터로 용암을 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »커피가루의 건조

카본 라인 히터로 커피 가루를 건조시키는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »기름의 건조

카본 라인 히터로 기름을 건조시키는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »퍼미큘라이트의 건조

카본 라인 히터로 퍼미큘라이트를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »고토 석회의 건조

카본 라인 히터로 고토 석회를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »가누마토의 건조

카본 라인 히터로 카누마토를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »펄라이트의 건조

카본 라인 히터로 펄라이트를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »제올라이트의 건조

카본 라인 히터로 제올라이트를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »하얀 모래의 건조

카본 라인 히터로 하얀 모래를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »아지노모토물의 건조

카본 라인 히터로 우마미 조미료를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More »물 녹는 밤나무 가루의 건조

카본 라인 히터로 수용 편 가루를 건조하는 데모입니다. 자세한 내용은 아래 사이트에서 확인하십시오.

Read More » HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵