This is a demonstration of drying eggless batter using a carbon line heater. Please check the following site for more information.

Read More »Drying soybean flour water

This is a demonstration of drying soybean flour water using a carbon line heater. Please check the following site for more information.

Read More »Drying salt water

This is a demonstration of drying salt water (brine )using a carbon line heater. Please check the following site for more information.

Read More »Drying sugar

A demonstration of drying sugar liquid using a carbon line heater. Please check the following site for more information.

Read More »Drying silicon oxide

This is a demonstration of drying silicon oxide using a carbon line heater. Please check the following site for more information.

Read More »Drying clay-based desiccants

This is a demonstration of drying clay-based desiccant using a carbon line heater. Please check the following site for more information.

Read More »Drying silica gel

This is a demonstration of drying silica gel with a carbon line heater. Please check the following site for more information.

Read More »Drying denim

A demonstration of drying denim fabric with a carbon line heater. Please check the following site for more information.

Read More »Drying nonwoven filters

This is a demonstration of drying a nonwoven fabric filter using a carbon line heater. Please check the following site for more information.

Read More »Drying lace dough

This is a demonstration of drying lace fabric with a carbon line heater. Please check the following site for more information.

Read More »Drying sheeting cloth

This is a demonstration of drying sheeting fabric using a carbon line heater. Please check the following site for more information.

Read More »Drying Oxford broadcloth

This is a demonstration of drying Oxford broadcloth with a carbon line heater. Please check the following site for more information.

Read More »Drying coffee filters

This is a demonstration of drying coffee filters using a carbon line heater. Please check the following site for more information.

Read More »Drying cardboard backing

This is a demonstration of drying cardboard backing with a carbon line heater. Please check the following site for more information.

Read More »Drying corrugated cardboard

This is a demonstration of drying corrugated cardboard using a carbon line heater. Please check the following site for more information.

Read More »Drying corrugated fiberboard

This is a demonstration of drying corrugated fiberboard using a carbon line heater. Please check the following site for more information.

Read More »Thermal Changes in Rubber Material by Localized Infrared Heating

Using a halogen point heater, we locally irradiated rubber material with infrared radiation and observed its thermal changes. As heating progressed, the rubber softened, expanded, and deformed while emitting white smoke. Additionally, cracks formed in the locally heated areas. Please ...

Read More »Thermal Decomposition of Polycarbonate Sheet by Localized Infrared Heating

Using a halogen point heater, we locally irradiated a polycarbonate (PC) sheet with infrared radiation and observed its thermal decomposition process. As heating progressed, the polycarbonate softened, and outgas was generated. Please check the following site for more information.

Read More »Thermal Decomposition of Acrylic Sheet by Localized Infrared Heating

When infrared radiation is locally applied to an acrylic sheet using a halogen point heater, thermal decomposition progresses, and outgas is generated. As the temperature rises further, white smoke appears, and decomposition accelerates. Please check the following site for more ...

Read More »Water droplet drying of Guasha plate

This is a demonstration of drying water droplets on a gua sha plate using the Carbon Line Heater. Please check the following site for more information.

Read More »Water droplet drying of Matte Coated Paper

This is a demonstration of drying water droplets on embossed coated paper using the Carbon Line Heater. Please check the following site for more information.

Read More »Water droplet drying of magnetic sheet

This is a demonstration of drying water droplets on a magnet sheet using the Carbon Line Heater. Please check the following site for more information.

Read More »Water droplet drying of blackened aluminum heat sink

This is a demonstration of drying water droplets on a black-dyed aluminum heat sink using the Carbon Line Heater. Please check the following site for more information.

Read More »Water droplet drying of pure copper heat sink

This is a demonstration of drying water droplets on a pure copper heat sink using the Carbon Line Heater. Please check the following site for more information.

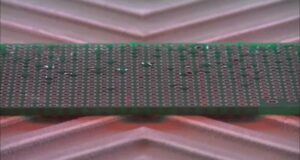

Read More »Water droplet drying of Bare board

This is a demonstration of drying water droplets on a bare board using the Carbon Line Heater. Please check the following site for more information.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop