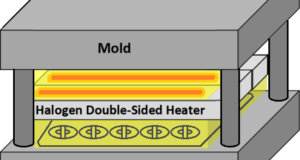

[ Problem Point ] To make the mold temperature more stable, it was necessary to preheat the mold before starting the molding cycle. [ ⇒Kaizen Point ] Preheated with a halogen double-sided heater. The waiting time for heating up can ...

Read More »No.2 Preheating aluminum die casting mold

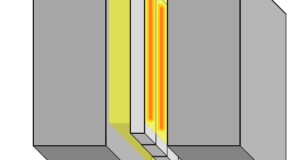

[ Problem Point ] Because the aluminum liquid cools too quickly, its fluidity decreases, leading to problems such as cold cracking, surface shrinkage, dendrites, hot spots, and wrinkles. [ ⇒Kaizen Point ] Preheated with a halogen double-sided heater. Preheating reduced ...

Read More »No.1 Preheating a small press mold

[ Problem Point ] We were looking for a heating method different from gas heating to preheat the mold. [ ⇒Kaizen Point ] Near-infrared heating, which has high heating efficiency for metals, has made it possible to replace gas heating.

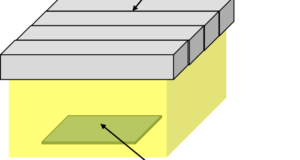

Read More »No.79 Preheating carbon fiber reinforced thermoplastic (CFRTP) before molding

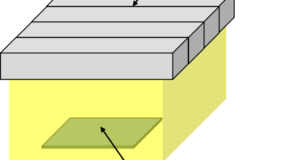

[ Problem Point ] I was looking for a method to preheat carbon fiber reinforced thermoplastic (CFRTP) before molding. [ ⇒Kaizen Point ] Since they can be used side by side, the number of heaters can be increased depending on ...

Read More »No.78 Drying dyed fabrics

[ Problem Point ] The maximum setting temperature of the heat setter used to dry dyed fabrics was low, resulting in slow feed speeds and poor productivity. [ ⇒Kaizen Point ] By using a halogen heater, the feed speed was ...

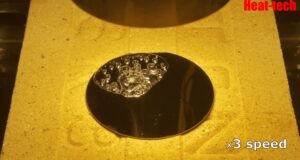

Read More »Heating purified water on a silicon wafer

This is a video of heating and evaporating purified water on a silicon wafer using a halogen point heater. Please check the following site for more information.

Read More »The secret of amethyst: Color that changes with heat

This is a video of heating amethyst with a halogen point heater to change its color. Please check the following site for more information.

Read More »Heating of emerald (Nanosital)

This video shows an emerald (Nanosital) being heated with a halogen point heater to change its color. Please check the following site for more information.

Read More »Pulse input heater controller for halogen heater HCP series

◆ Feature ◆ It can flash the halogen heater with a 0-5V pulse. Lock-in infrared exothermic analysis – can be used for lock-in thermography methods. Sine curve irradiation of a halogen heater can be performed with a voltage of 0-5V. Example By ...

Read More »No.77 Infrared irradiation test

[ Problem Point ] We were looking for a way to simulate the stress caused by heating a sample to high temperatures. [ ⇒Kaizen Point ] Since they can be used side by side, the number of heaters can be ...

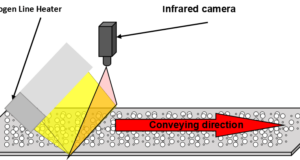

Read More »No.76 Infrared foreign object inspection device

[ Problem Point ] I was looking for a near-infrared heater capable of wire heating to be introduced into a foreign object inspection device. [ ⇒Kaizen Point ] Since the output can be varied and the temperature can be adjusted, ...

Read More »Make a hole in plastic bottle using infrared rays

This video shows a hole being made in a plastic bottle using a halogen glass rod heater. Please check the following site for more information.

Read More »Make a hole in plastic bottle caps using infrared rays

This video shows making a hole in a PET bottle cap by infrared rays using a halogen glass rod heater. Please check the following site for more information.

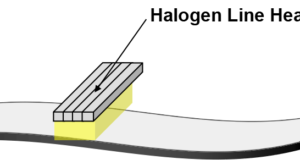

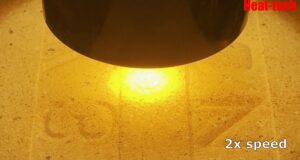

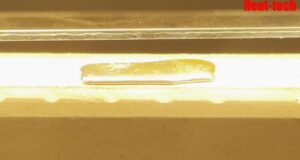

Read More »Melting of lead

This video shows lead being melted using a halogen line heater. Please check the following site for more information.

Read More »Melting of bismuth

This video shows bismuth being melted using a halogen line heater. Please check the following site for more information.

Read More »Pinpoint heating of 0.5mm mechanical pencil lead

This is a video of pinpoint heating of 0.5mm mechanical pencil lead using a halogen point heater. Please check the following site for more information.

Read More »Resin heating during heat caulking process

This is a video of heating the resin during the thermal caulking process using a halogen glass rod heater. Please check the following site for more information.

Read More »Deburring polypropylene resin products

This is a video of deburring polypropylene resin using a halogen glass rod heater. Please check the following site for more information.

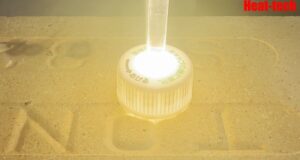

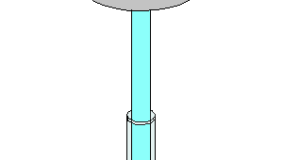

Read More »Direct heating of water in test tubes

This video shows a halogen glass rod heater inserted into water in a test tube and heated. Please check the following site for more information.

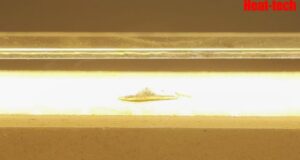

Read More »Pinpoint heating of solder

This is a video of pinpoint heating of solder with a halogen glass rod heater. Please check the following site for more information.

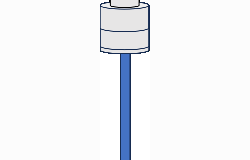

Read More »Halogen Glass Rod Heater Products

Halogen Glass Rod Heater HGRH-45 HGRH-70 Heater Controller HCV Series Manual power controller HCV Series for Halogen heater HHC Series Overview of the high-performance heater controller HHC2 series SSC Series Condition setting ,confirmation and recording, Overview of ...

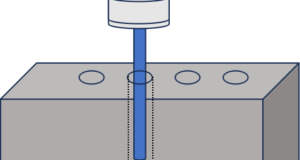

Read More »No.4 Drying screw holes after cleaning

[ Problem Point ] I was having trouble with water remaining in the deep screw holes after cleaning. [ ⇒Kaizen Point ] Since it could be inserted into a deep hole and heated, it was able to dry efficiently.

Read More »No.3 Micro/nanoscale material testing

[ Problem Point ] I was looking for a heater that provides pinpoint heating to use when measuring the properties of extremely small materials. [ ⇒Kaizen Point ] Halogen glass rod heaters can provide localized heating, minimizing thermal stress on ...

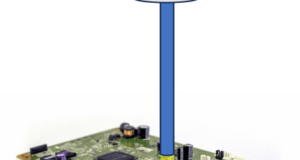

Read More »No.2 Soldering electronic components

[ Problem Point ] I was looking for a soldering method that would not affect other parts with heat. [ ⇒Kaizen Point ] Halogen glass rod heaters can provide localized heating, minimizing thermal stress on other parts.

Read More »No.1 Heating the liquid in the test tube

[ Problem Point ] I was looking for a heater that directly heats acidic solutions and special liquids. [ ⇒Kaizen Point ] Since the temperature can be controlled, stable heating can now be achieved at the desired temperature.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop