INDEX

Overview of the high-temperature heating method

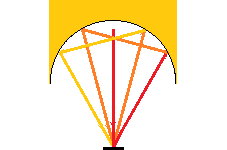

Concentrating heating using a halogen lamp uses a condensing mirror to concentrate light energy on the object to be heated to a high temperature.

Of the light incident on the object to be heated, the more reflected light excluding absorbed light, the lower the temperature of the object will be. Heating using only a condensing mirror reduces the utilization of this reflected light.

In the high-temperature heating method, this reflected light can be reused by using reflective materials to contribute to raising and uniformly heating the object to a high temperature.

Heating of highly reflective materials

Materials with high reflectivity and low infrared absorptivity reflect infrared rays and diffuse heat energy and can not reach high temperatures.

Diffused thermal energy can be recycled to high temperatures using reflectors.

Heating of tiny materials

The smaller the mass, the faster the temperature rises when heated.

The high temperature heating method is suitable for heating extremely small materials at high temperatures. Using only a condensing mirror, it is possible to reach a much higher temperature than the heating method.

Uniform heating

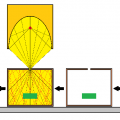

In condensed heating using a halogen lamp, the heat source is a point or line. For this reason, it is often thought that heating in a “plane” shape is difficult.

By changing the irradiation distance and shifting the focus, it is possible to heat the shape of the surface using condensed light heating. Uses The high temperature heating method for more even heating.

Material of reflector

Gold-plated mirror

It is a highly reflective gold plated material.

Gold plating is difficult to discolor and has excellent corrosion resistance.

Aluminium polishing mirror

Polished aluminum is a cost-effective and highly reflective material.

Reflectance is approximately 10% lower compared to gold plating.

It can be repolished, so it can be used for a long time if taken care of.