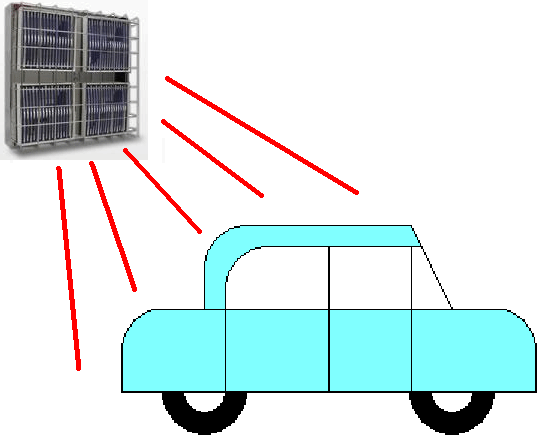

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Dried by the Ir Panel Heater. Since the dryer is heated quickly, no longer waiting time. Now able to respond flexibly to unexpected interrupt ...

Read More »No.19 Recovery of resin mold

[ Problem Point ] We were in trouble because there were no deburring methods of a resin mold. [ ⇒Kaizen Point ] An abuse moth just applied hot air lightly by the Air Blow Heater, and went off easily. Yield ...

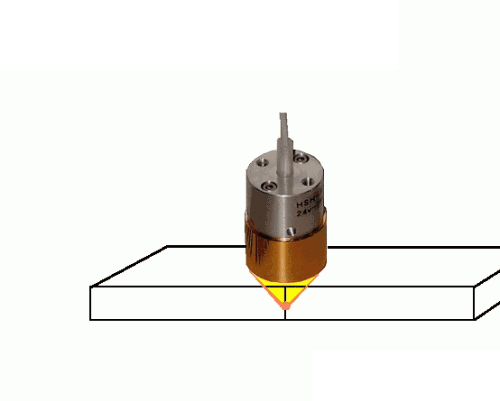

Read More »No.14 Plastic resin welding

[ Problem Point ] It was no easy way to trouble-free welding without oxygen. [ ⇒Kaizen Point ] Welded by the small point halogen heater. Easily welded in nitrogen atmosphere. Junction with improved quality.

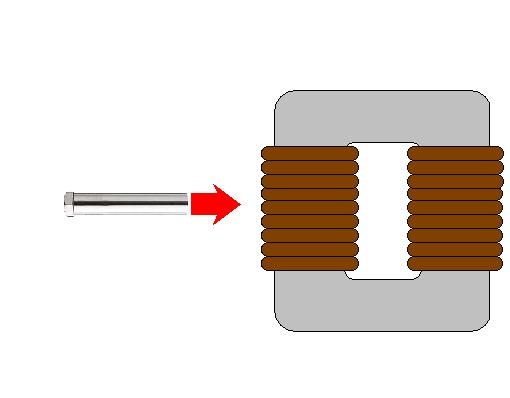

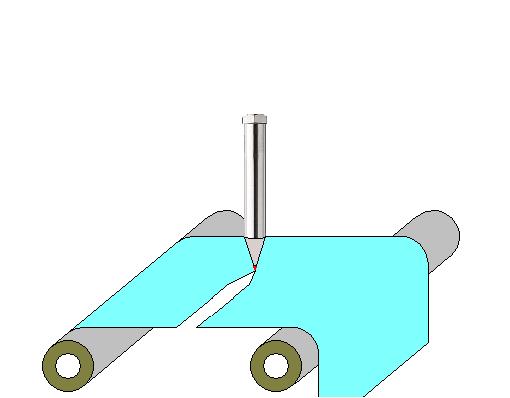

Read More »No.17 Self-bonding wire coil wound

[ Problem Point ] The rolling mark remained in the thin line and we were in trouble. [ ⇒Kaizen Point ] The smooth back into the twisting winding heating the Air Blow Heater Self-bonding caused by heating up the coil ...

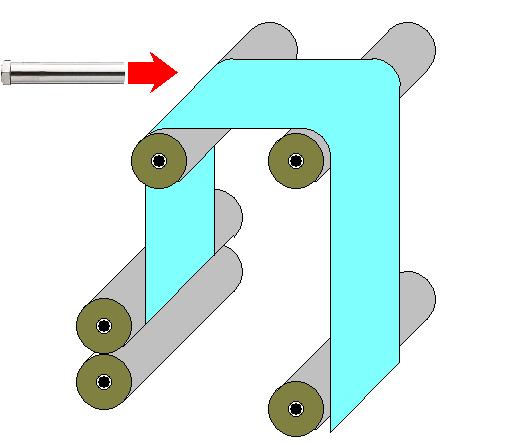

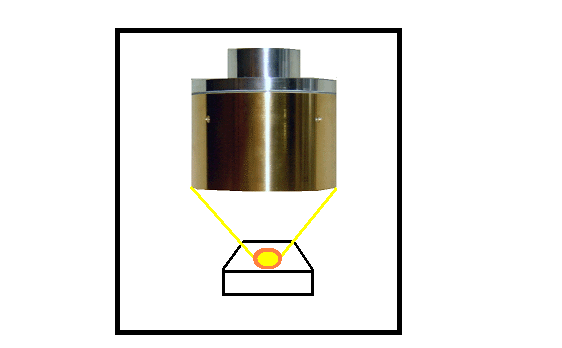

Read More »No.13 Forming of the multilayer polymer film

[ Problem Point ] There was no heater can heat to penetrate the polymer film on the upper side metallic mold. [ ⇒Kaizen Point ] We use the Halogen Point Heater Because the halogen point was heated to pinpoint the ...

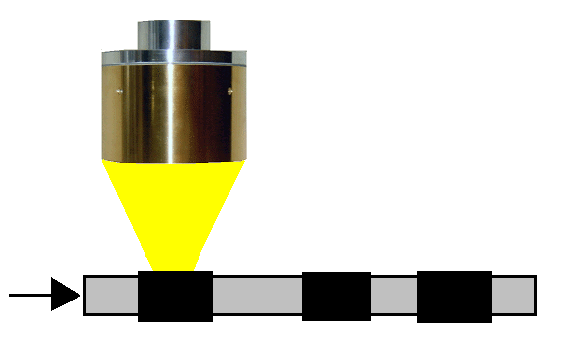

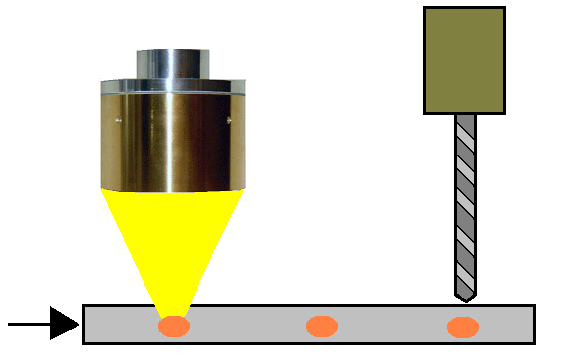

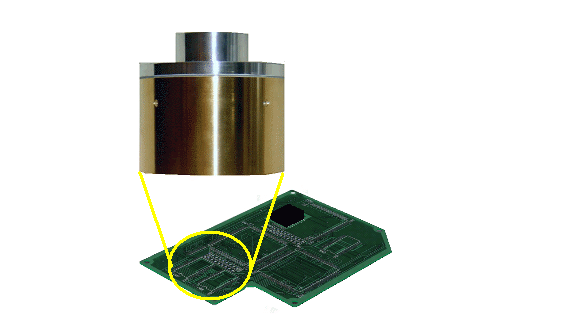

Read More »No.16 Soldering of printed circuit board

[ Problem Point ] We were in trouble because we couldn’t soften cream solder effectively. [ ⇒Kaizen Point ] We have heated the small spot by an extraordinarily small Air Blow Heater and have solved problems.

Read More »No.12 Heating of heat-shrinkable tubing

[ Problem Point ] Heatproof of the heat-shrinkable tubing and heatproof of the sheath of the electric wire were different, and the electric wire scorched. [ ⇒Kaizen Point ] The tube heated with the Halogen Point Heater. Shrinkage went well ...

Read More »No.11 Preheating of bending work

[ Problem Point ] The crack happened and very troubled. [ ⇒Kaizen Point ] The pipe preheated with the Halogen Point Heater. The surface tensity was removed because it heated at the suitable temperature and the crack disappeared.

Read More »No.1 Small dry oven

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Heated by the Ir Panel Heater. Since rapid heating, increased uptime. Now able to respond flexibly to unexpected interrupt work.

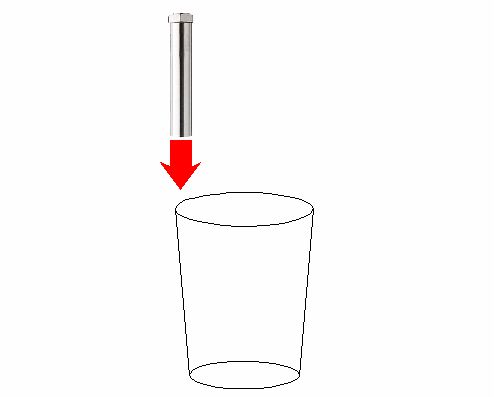

Read More »No.13 Dryness of printed matter

[ Problem Point ] Air blow dry was being done in room temperature,but we were in trouble because it wasn’t dried. [ ⇒Kaizen Point ] Air blow dry was done by the Air Blow Heater.It was appropriate temperature control and ...

Read More »No.12 Dryness of a coater

[ Problem Point ] Air blow dry was being done in room temperature,but we were in trouble because it wasn’t dried. [ ⇒Kaizen Point ] Air blow dry was done by the Air Blow Heater. It was appropriate temperature control ...

Read More »No.10 Removal of the surface tension of the pipe hole drilling

[ Problem Point ] The hole crack happened and very troubled. [ ⇒Kaizen Point ] The pipe preheated with the Halogen Point Heater. The surface tensity was removed because it heated at the suitable temperature and the crack disappeared.

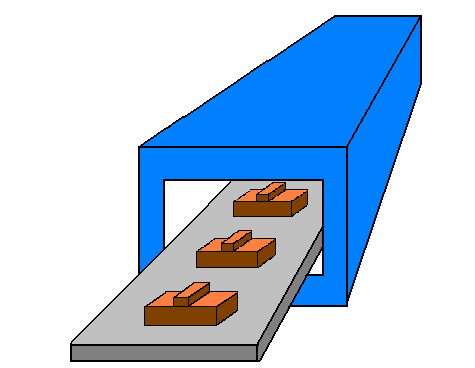

Read More »No.11 Heating cutoff of resin seat

[ Problem Point ] Resin seat was cut by a blade, it comes loose from the end,and we were in trouble. [ ⇒Kaizen Point ] Hot wind was narrowed down to a pinpoint by the taper type of the Air ...

Read More »No.9 Sintering examination of ceramics

[ Problem Point ] We have no idea about good way to easily control and hot quickly. [ ⇒Kaizen Point ] The ceramics was high temperature heated with the Halogen Point Heater small point. The sintering examination went well because ...

Read More »No.8 Dryness of print

[ Problem Point ] We have no idea about good way to point in the dry heat. [ ⇒Kaizen Point ] Raised the temperature in 15 seconds with the Halogen Point Heater. So clear that the target could prevent heat ...

Read More »No.7 Test piece heating in the vacuum chamber

[ Problem Point ] We have no idea about how to test piece heating in the vacuum chamber. [ ⇒Kaizen Point ] The Halogen Point Heater has turned up the heat to 1400℃ momentarily. The change in the material occurred ...

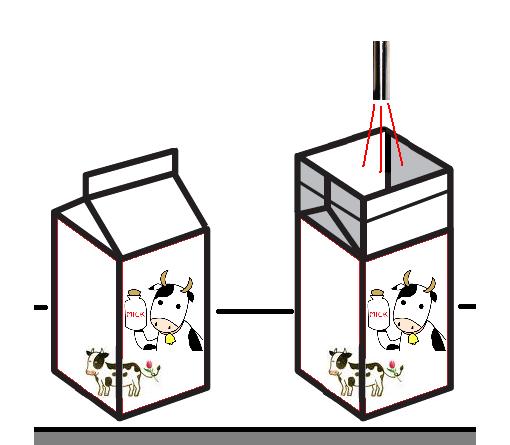

Read More »No.8 Heat sealing of paper carton

[ Problem Point ] When it was heated, paper caught fire,and we were in trouble about gas. [ ⇒Kaizen Point ] It was heated, and did heat sealing of a spot by the Air Blow Heater It could be worked ...

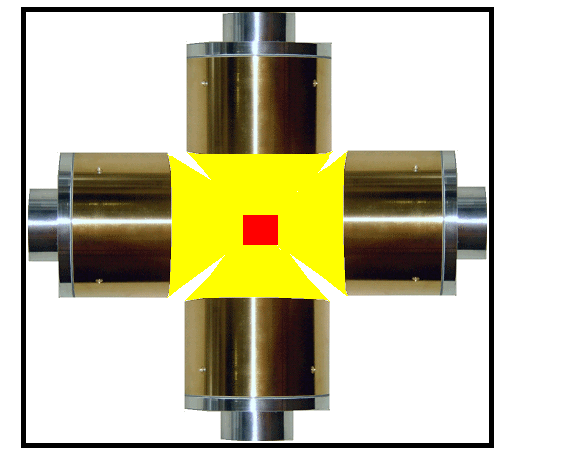

Read More »No.6 Heat source of heat power generation examination system

[ Problem Point ] We have no idea about how to heat source of heat power generation examination system. [ ⇒Kaizen Point ] The heat power generation module generates electricity by heating the surface and cooling the back. The Halogen ...

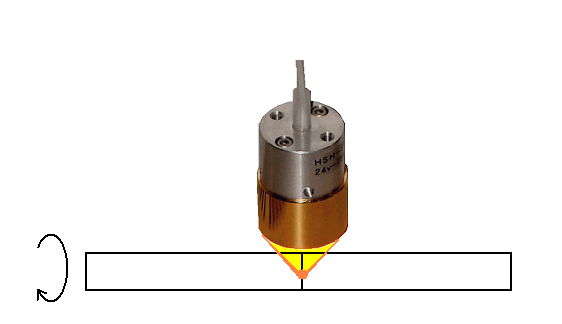

Read More »No.7 Torch of the resin weld

[ Problem Point ] There was nothing good as a torch for resin welds,and we were in trouble. [ ⇒Kaizen Point ] Spot was heated by the Air Blow Heater and resin was welded. The finish could heat a pinpoint, ...

Read More »No.5 Optical siphon table

[ Problem Point ] We were embarrassed because there was being able no gas piping. [ ⇒Kaizen Point ] The siphon was heated with the Halogen Point Heater. The design of the layout of the store became free because it ...

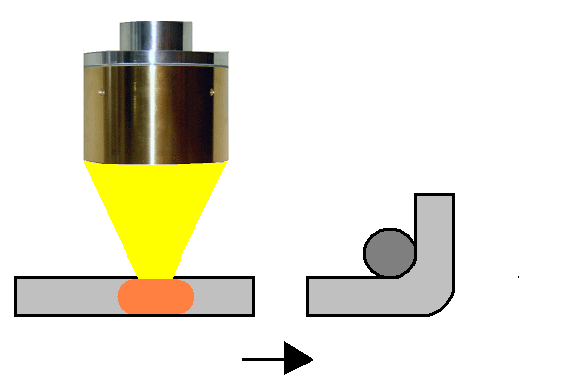

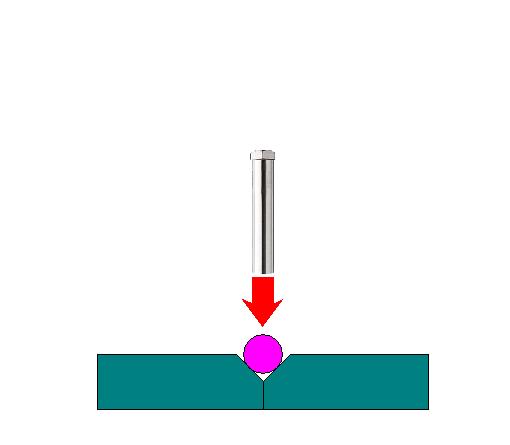

Read More »No.4 Joint of thermoplastic resin tubes

[ Problem Point ] We have no idea about how to joint of thermoplastic resin tubes. [ ⇒Kaizen Point ] The thermoplastic resin tube was joined with the Halogen Point Heater. The heating melt was done, and the central portion ...

Read More »No.5 Heat-shrinkable tubing

[ Problem Point ] We were in trouble about a dryer for industry because devices burned out because the area was too wide. [ ⇒Kaizen Point ] We heated only a lead by a small spot by the Air Blow ...

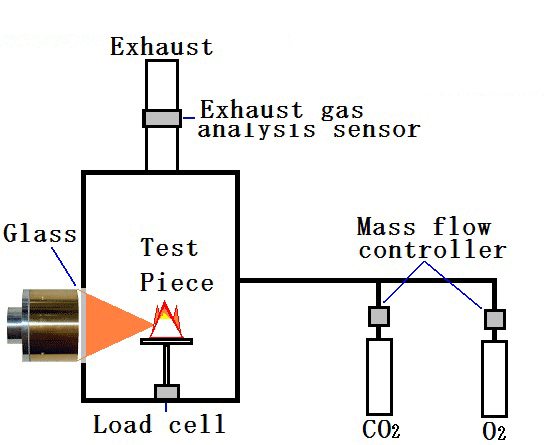

Read More »No.3 Burning in low oxygen density environment

[ Problem Point ] We have no idea about how to burning in low oxygen density environment. [ ⇒Kaizen Point ] The radiant heat was given with the Halogen Point Heater. The gas analysis in the burning gas became possible ...

Read More »No.4 Film shrink

[ Problem Point ] Dryer for industry was being used. Without being made,accurate temperature control would be a problem. [ ⇒Kaizen Point ] We can control the accurate temperature by the Air Blow Heater, so wrinkles and a spot of ...

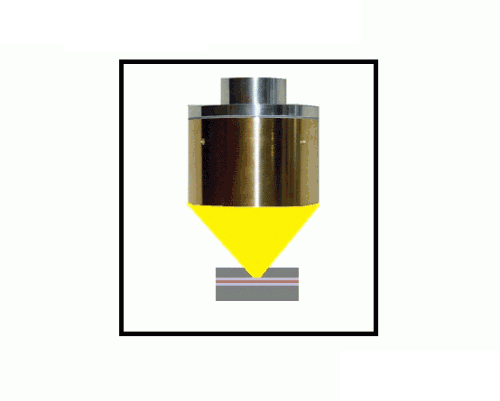

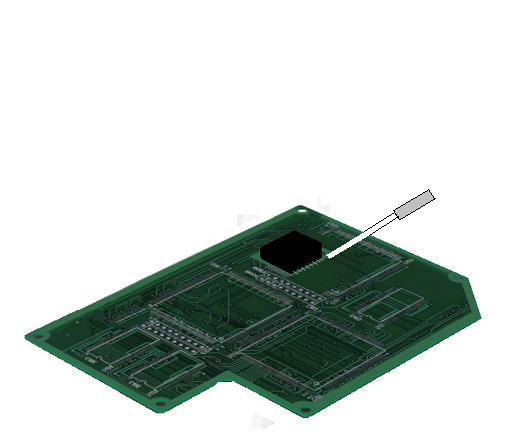

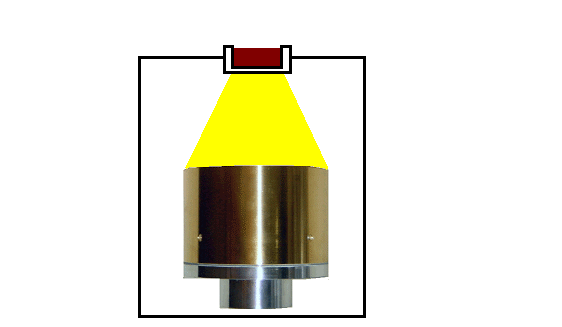

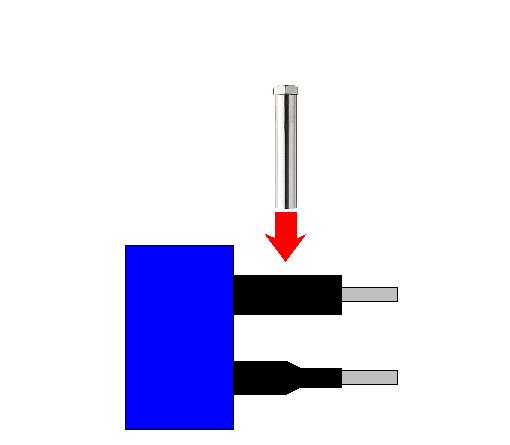

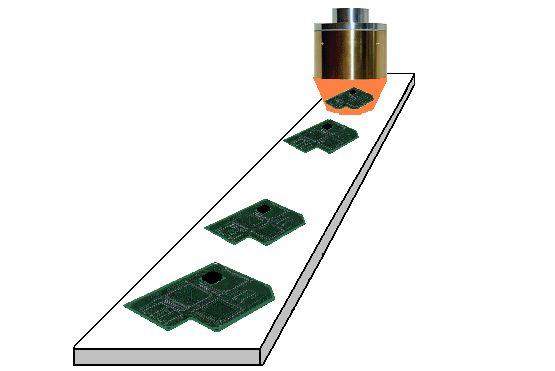

Read More »No.2 Preheat of printed circuit boards

[ Problem Point ] We have no idea about how to preheat of printed circuit boards. [ ⇒Kaizen Point ] Preheated and out of focus the Halogen Point Heater. Elevating the temperature time is short, it worked so easy soldering ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop