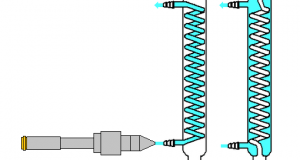

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

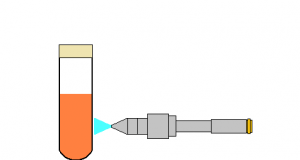

Read More »No.4 Test tube cooling

《Problem Point 》 There was no good equipment to cool the test tube. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the Air Cooler Controller, the inspection accuracy has increased.

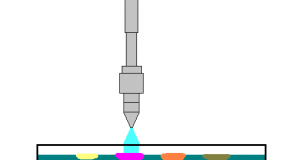

Read More »No.3 Partial cooling of medium

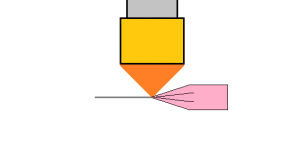

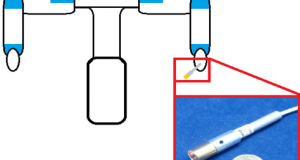

《Problem Point 》 There was no good equipment to pinpoint the medium to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

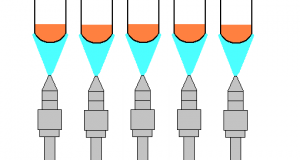

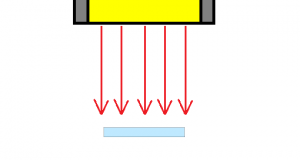

Read More »No.2 Low temperature drying of vials

《Problem Point 》 There was no good equipment for low temperature drying vials. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the cool air cooler controller, the tact time can be ...

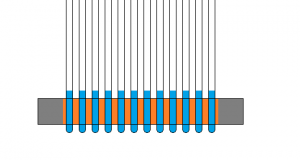

Read More »No.1 Vial cooling

《Problem Point 》 There was no good equipment to pinpoint the vials to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.113 Activated carbon regeneration

[ Problem Point ] There was no device that was small and could be inlined. [ ⇒Kaizen Point ] Using hot air heater environment resistant type DGH series, Heated steam was blown into the activated carbon. The accumulated dirt was ...

Read More »Heating of glass and Zinc powder

This video is heating of glass and Zinc powder by the Halogen Point Heater. Please check the following site for more information.

Read More »No.3 Heating of glass plate

[ Problem Point ] There was ot a method to heat a part of the glass plate with far infrared rays. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FLH-35. The glass plate could be heated.

Read More »No.1 Heating of test tube

[ Problem Point ] There was not a method to heat a part of test tube in far infrared rays. [ ⇒Kaizen Point ] Heated using a far infrared line heater FLH-30. Glass and a liquid were able to heat ...

Read More »No.1 Pinpoint heating of resin

[ Problem Point ] There was no compact heater of far infrared which can pinpoint point the resin. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-30. The welding of the resin got to work gently.

Read More »No.20 Promotion of plastic polymerization

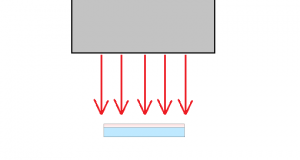

[ Problem Point ] We were looking for a heater that can heat steadily without contact. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since temperature control can be done in increments of 1℃, the optimum conditions ...

Read More »No.19 Heat synthesis of proteins

[ Problem Point ] We were looking for a heater that can heat steadily without contact. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since temperature control can be done in increments of 1℃, the optimum conditions ...

Read More »No.18 Heating of wool

[ Problem Point ] We were looking for a heater that can heat steadily without contact. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since PHX is a panel heater, PHX is able to heat the whole ...

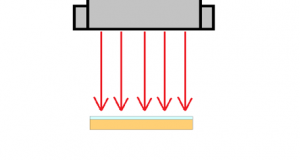

Read More »No.17 Preheating of prepreg

[ Problem Point ] There was no heater which can heat the entire body uniformly. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since PHX is a panel heater, PHX is able to heat the whole uniformly.

Read More »No.16 Multistage heating of tire

[ Problem Point ] We needed a heater with good responsiveness capable of multistage heating. [ ⇒Kaizen Point ] Heating with a momentary temperature rise far-infrared panel heater PHX. Since it can follow chemical changes, PHX was able to do ...

Read More »No.6 Control of a dry time for solvent system adhesive

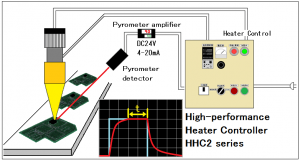

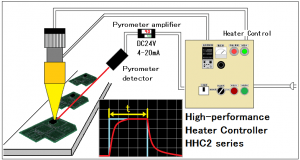

[ Problem Point ] It took a certain amount of curing at a stable temperature without overshoot. [ ⇒Kaizen Point ] Using the heat retention time control function of highly functional heater controller HHC2. The heating time was tested in ...

Read More »No.5 Heating time control for condition setting

[ Problem Point ] It was necessary to set conditions as to whether heating could be done within the takt time. [ ⇒Kaizen Point ] Using the heat time control function of highly functional heater controller HHC2. The heating time ...

Read More »No.37 Heating processing of the double-arm robot

[ Problem Point ] There was no compact heater that can be mounted on a dual arm robot. [ ⇒Kaizen Point ] It was heated using microminiature Halogen Point Heater HPH-12. Handling became easy since it is a finger size ...

Read More »No.54 Borosilicate glass plate melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass plate was melted using a halogen line heater. The glass tube processing process was composed only by electric equipment. In addition, ...

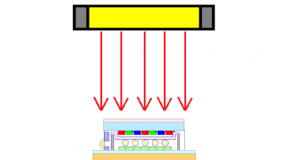

Read More »No.53 Heat test of the color filter

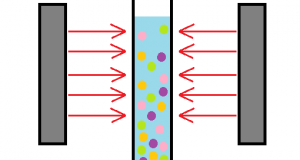

[ Problem Point ] It is necessary to shorten the new development time of a color filter. [ ⇒Kaizen Point ] We were using the parallel light type halogen line heater. Since the halogen heating type, it was able to ...

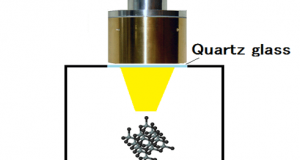

Read More »No.35 Calcination of SiC silicon carbide

[ Problem Point ] There were no sources of heat which can easily heat SiC silicon carbide. [ ⇒Kaizen Point ] SiC silicon carbide was heated using the Halogen Point Heater. As it became the high temperature in a short ...

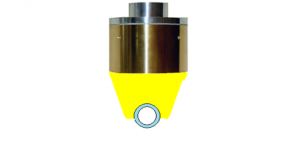

Read More »No.34 Borosilicate glass tube melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass tube was melted using a halogen point heater. The glass tube processing process was composed only by electric equipment. In addition, ...

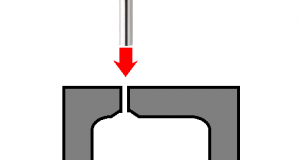

Read More »No.103 Molding of a polyethylene container

[ Problem Point ] The reduction of the defectiveness rate was necessary. [ ⇒Kaizen Point ] We ware molded using the Air Blow Heater. Since the heating air fluidity of the resin is improved.

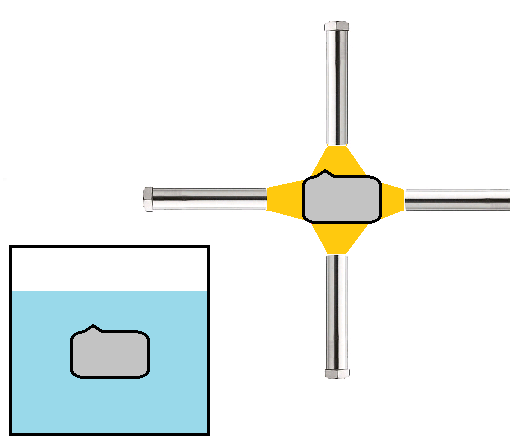

Read More »No.102 Drying after the leak test using a water tank

[ Problem Point ] Shortening of the dry time was necessary. [ ⇒Kaizen Point ] We ware heated to work by using the Air Blow Heater. Dry time became short more markedly than air blow drying. Installation because it does ...

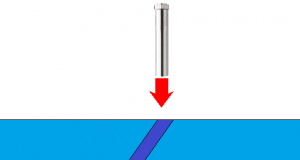

Read More »No.101 Adhesion of PVC sheet

[ Problem Point ] The exact temperature control was necessary. [ ⇒Kaizen Point ] We adhered to PVC sheet using the Air Blow Heater. Rise early, it has allowed accurate temperature control. Besides, it became the maintenance-free as Air Blow ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop