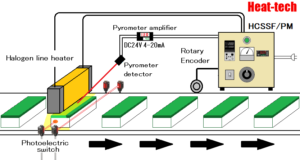

[ Problem Point ] There was no heater controller that could heat intermittently Even when there was no work, the heater was operating and power was wasted. Also, when the line stopped, cracks occurred in the dry part. And when ...

Read More »No.63 Evaluation of thermal responsiveness of thin ceramic plates

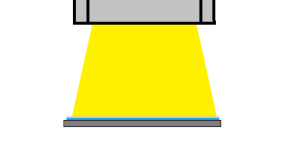

[ Problem Point ] We were looking for a heater to supplement the amount of heat dissipated from the thin plate. [ ⇒Kaizen Point ] Using a fast response halogen line heater. The accuracy of the feedback evaluation experiment has ...

Read More »No.62 Evaluation of metal heat storage material

[ Problem Point ] High speed heating was required to evaluate the responsiveness of the heat storage material. [ ⇒Kaizen Point ] Uses a halogen line heater that instantly heats up, The speed of the evaluation experiment has increased. I ...

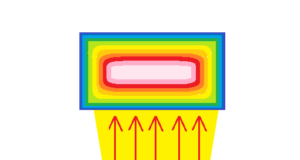

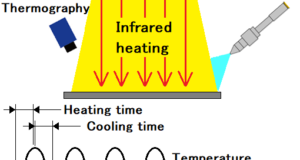

Read More »No.59 Lock-in infrared heat generation analysis-Lock-in thermography method

[ Problem Point ] We were looking for a heater that would synchronize with the pulse signal. [ ⇒Kaizen Point ] By changing the applied frequency, it was possible to limit the area of the heat generation point. When applied ...

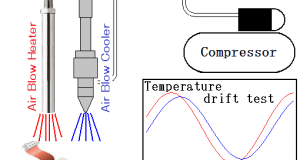

Read More »No.30 Temperature drift test of electronic devices

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

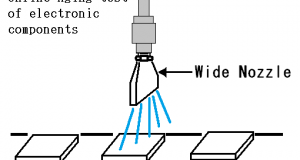

Read More »No.29 Low temperature aging of electronic parts

《Problem Point 》 There was no good equipment for in-line low temperature electronic components. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Furthermore, since the set temperature can be maintained with the cool air cooler controller, the product quality ...

Read More »No.28 Evaluation of low temperature operation of semiconductors

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.26 Cold resistance test of color filter

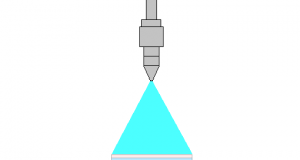

《Problem Point 》 There was no good equipment to cool the color filter. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the Air Cooler Controller, the inspection accuracy has increased.

Read More »No.17 Cooling and solidification of resin solvent

《Problem Point 》 There was no good equipment to cool and solidify the resin solvent. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since it can be dried under reduced pressure with cold air, the tact time can be ...

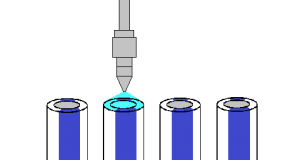

Read More »No.16 Electronic component cooling test

《Problem Point 》 There was no good equipment to pinpoint the electronic component to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be ...

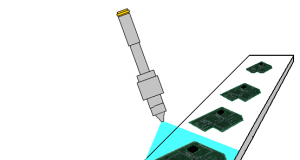

Read More »No.15 Printed circuit board cooling

《Problem Point 》 There was no good equipment to cool the printed circuit board after soldering. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the cool air cooler controller, the tact ...

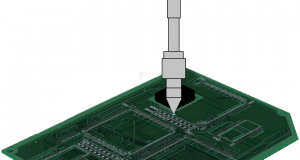

Read More »No.14 Rapid soldering cooling

《Problem Point 》 There was no good equipment to pinpoint the soldering to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.11 Cooling and solidification of 3D printer

《Problem Point 》 There was no good equipment to pinpoint the modeling to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.58 Improved affinity for metal thin films

[ Problem Point ] The affinity of the metal thin film was not good. [ ⇒Kaizen Point ] The metal was heated and activated, and the affinity was improved.

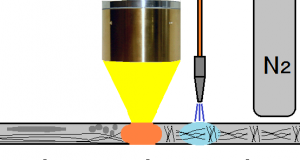

Read More »No.57 Surface modification of resin

[ Problem Point ] The hydrophilicity of the resin was not good. [ ⇒Kaizen Point ] Gas was brought into contact with the resin and irradiated with a halogen line heater. A synthetic thin film was formed on the surface, ...

Read More »No.44 Thermal expansion evaluation of a special alloys

[ Problem Point ] There was no easy precision heating method for semiconductors. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature by feedback control with near ...

Read More »No.43 Thermal expansion evaluation of semiconductors

[ Problem Point ] There was no easy precision heating method for semiconductors. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature by feedback control with near ...

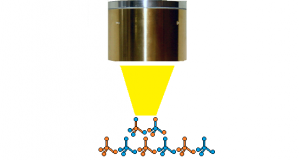

Read More »No.42 Synthesis of alloy particle

[ Problem Point ] There was no way to easily heat the metal particles to a high temperature. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature ...

Read More »No.41 Development of crystal structure of magnetic substance

[ Problem Point ] There was no way to heat at any temperature and cool at any temperature to develop the crystal structure. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Since ...

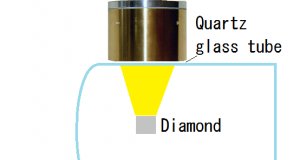

Read More »No.39 Trial manufacture of diamond quantum sensor

[ Problem Point ] There was no way to easily bring the diamond in the glass tube to 1000℃ [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. The equipment became smaller and ...

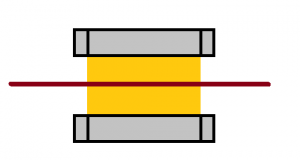

Read More »No.2 Hardening of Teflon coated wire

[ Problem Point ] Teflon resin could not be hardened with general heater. [ ⇒Kaizen Point ] Heated using a far infrared line heater FLH-30. The curing reached well by using far infrared rays.

Read More »No.2 Heat source for the inspection of the fire detector

[ Problem Point ] There was not a method to inspect a fire detector according to a frequency. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-60. It was able to easily change the frequency of ...

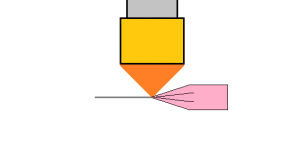

Read More »No.1 Pinpoint heating of resin

[ Problem Point ] There was no compact heater of far infrared which can pinpoint point the resin. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-30. The welding of the resin got to work gently.

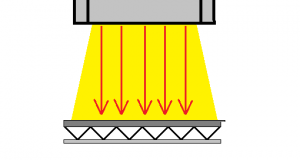

Read More »No.56 Heating of high temperature insulation material

[ Problem Point ] The creep characteristic of the high temperature heat insulating material could not be grasped. [ ⇒Kaizen Point ] And heated at high temperature using a halogen line heater. Since it can be heated to any temperature ...

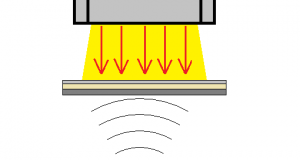

Read More »No.55 Heating of microwave absorbing composite

[ Problem Point ] Microwave absorption characteristics of composite materials under high temperature environments could not be grasped. [ ⇒Kaizen Point ] Heated at high temperature using a halogen line heater. Since it can be heated to an arbitrary temperature ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop