為了提高溫度測量的準確性,選擇**「何時測量」**即測量時機至關重要。即使是相同的測量對象,由於加熱或冷卻的進行狀況、周圍環境的變化以及測量對象的熱慣性等因素的影響,測得的溫度可能會有所不同。如果未能在適當的時機進行測量,將無法準確掌握實際溫度,並可能導致測量結果與預期目標不符。

例如,在使用鹵素加熱器對厚金屬進行加熱的過程中,表面溫度會迅速上升,但內部溫度需要較長時間才能達到同樣的水平。此外,在戶外或工廠等環境中,由於測量時間或周圍溫度的變化,測量數據可能會有所波動,因此必須適當管理測量時機。

本章將詳細說明影響測量時機的三個主要因素:

1. 加熱與冷卻過程造成的溫度變動

2. 環境溫度變化的影響

3. 測量對象的熱慣性影響

7.1 溫度變動的因素及其影響

溫度並非恆定,而是隨時間變化。如果測量時機選擇不當,所得結果可能與實際溫度不符,從而降低測量數據的可靠性。以下將詳細解釋測量時機對溫度變動的影響。

7.1.1 加熱與冷卻過程造成的溫度變動

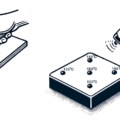

在加熱與冷卻過程中,不同的測量時機會導致不同的測量結果。特別是在使用鹵素加熱器等紅外線加熱技術時,熱能直接照射區域與未照射區域之間會產生溫差,因此若測量時機及位置選擇不當,將無法獲得準確的溫度數據。

鹵素加熱器加熱過程中的溫度變動

加熱開始後的初期:表面溫度迅速上升,但內部溫度變化緩慢。

持續加熱時:內部溫度逐漸上升,表面與內部的溫差逐漸縮小。

加熱完成並穩定後:內部與表面溫度趨於均勻,此時可獲得穩定的測量數據。

適當的測量時機

1. 等待加熱或冷卻完成,確保內部溫度均勻後再進行測量。

2. 測量時需考慮內部溫度與表面溫度,而非僅測量表面溫度。

3. 在溫度快速變化的階段,應進行多次測量,以提高數據的準確性。

7.1.2 環境溫度變化的影響

測量結果不僅受測量對象本身的影響,還會受到周圍環境溫度變化的影響。特別是在戶外環境測量或受空調運行影響的室內測量中,測量時間可能會導致數據出現較大變化,因此不容忽視。

1. 戶外環境的影響

早晨、白天與夜晚的氣溫差異大,若測量時間不同,數據比較將變得困難。

例:夏季時,柏油路面溫度在白天可超過 60℃,但到了夜晚可能會降至 30℃ 以下。

2. 室內環境的影響

空調運行狀態及人員進出會影響室溫,導致測量數據隨時間變動。

例:工廠內部因機械運行導致室內溫度上升,因此即使進行相同測量,不同時間獲得的數據可能有所不同。

應對措施

1.統一測量時間,確保在相同條件下進行測量,以便比較數據。

2.選擇不易受環境溫度影響的位置或時間進行測量。

3.透過連續測量並取平均值來減少環境溫度變動帶來的影響。

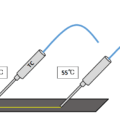

7.1.3 測量對象的熱慣性影響

熱慣性(Thermal Inertia)指的是物體對溫度變化的反應延遲,其主要受熱容量與熱傳導率的影響。尤其是熱容量較大的物體,其溫度變化較緩慢,若熱傳導速率較低,則內部溫度分佈的變化也會延遲。因此,測量時機的選擇會直接影響測量結果。

熱慣性對測量的影響案例

1. 金屬塊的加熱

加熱初期:表面溫度迅速上升,但內部溫度幾乎沒有變化。

數小時後:熱量傳遞至內部,此時可測得均勻的溫度數據。

2. 厚塑膠零件

快速加熱時:表面短時間內迅速升溫,但內部溫度上升較慢。

經過一段時間後:熱量滲透至內部,可獲得穩定的測量結果。

適當的測量時機

等待測量對象的內部溫度穩定後再測量。

為提高測量精準度,應進行多次測量並比對數據。

測量厚重物體時,需考慮表面溫度與內部溫度的差異。

7.2 總結

若測量時機選擇不當,可能會導致測得的溫度與實際溫度有所偏差。通過選擇適當的測量時機,可以獲得更可靠的數據。

選擇適當測量時機的關鍵點

✅ 確保加熱或冷卻過程完成,並待內部溫度穩定後再測量。

✅ 測量時考慮內部溫度與表面溫度,避免僅測量表面溫度。

✅ 統一測量時間,降低環境溫度變化帶來的影響。

✅ 在溫度變化較快的情況下,透過多次測量提高數據準確性。

選擇適當的測量時機,是精確溫度管理的關鍵。

HEAT-TECH 最佳技術網店

HEAT-TECH 最佳技術網店