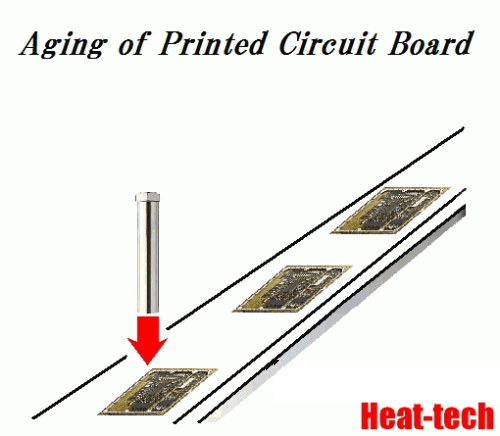

[ Problem Point ]

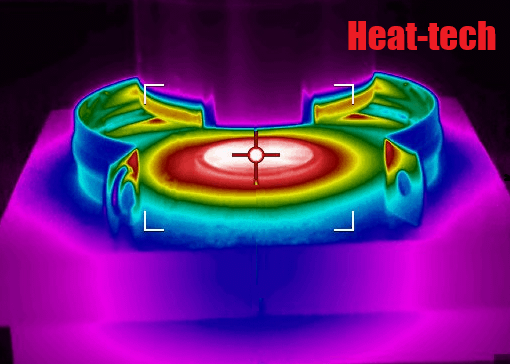

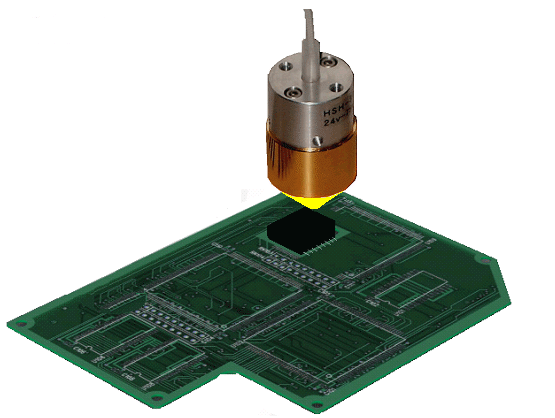

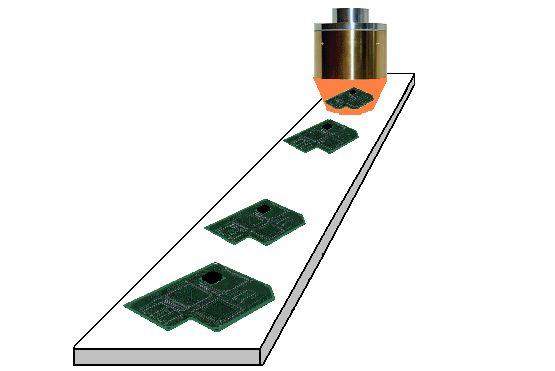

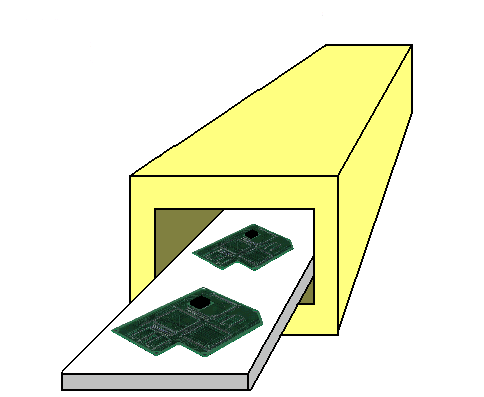

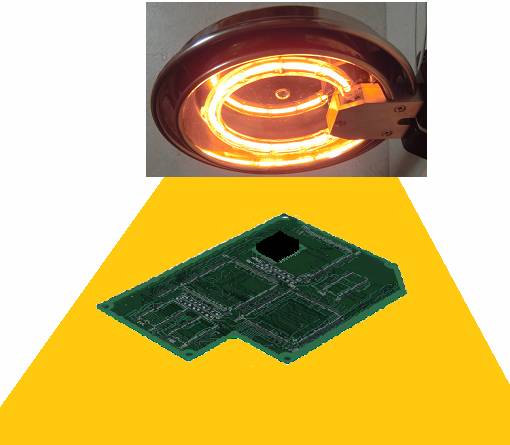

To accurately measure the thermal deformation of printed circuit boards, a heat source capable of providing uniform and instantaneous heating is required. However, conventional heaters suffer from uneven heating and slow response times. Additionally, the long heat-up time makes repeated short-term measurements difficult, reducing the reproducibility of measurement data.

[ ⇒Kaizen Point ]

By using the Carbon Line Heater (CFLH) to apply uniform and rapid heating to the printed circuit board, the accuracy of thermal deformation measurement has been improved. Since CFLH allows instant heating and cooling, measurement repeatability has been enhanced, enabling the acquisition of more detailed data in a shorter time. Furthermore, the finer heating cycles have made it possible to detect minute thermal deformations that were previously undetectable, leading to more accurate quality evaluations of circuit boards.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop