INDEX

To say that “drying”, there is a dry work of three types.

They are dryness of surface water of adhesion, dryness of a coat, and internal dryness of material.

Since internal dryness has been explained until now, describes the drying of the coating film.

3-8-1.Formation of a surface coating by immobilization of the binder

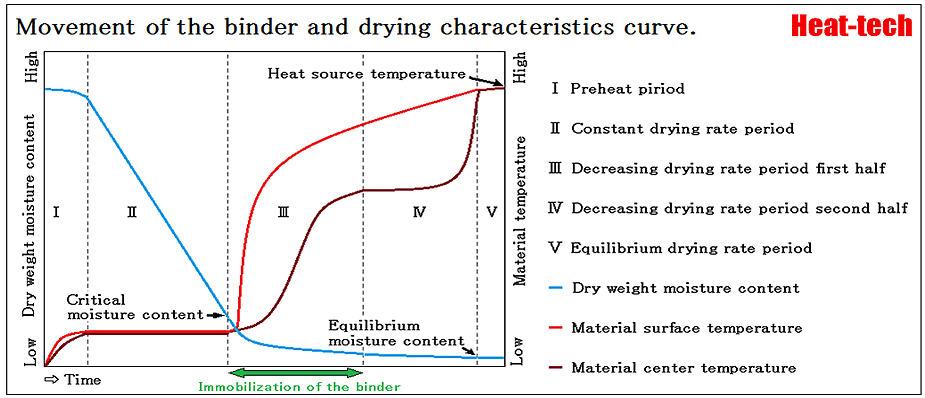

The drying of the coating, the moisture is moved towards the surface from the interior, non-volatile solutes contained in the moisture (binder) is concentrated on the surface with a dry, segregation of the composition occurs in the film inside.

In this case, the composition distribution can be calculated by solving the basic equations of the dry solute diffusion coefficient of moisture and if known.

Evaporation can not be moisture trapped inside by the immobilization of the binder, osmosis certain conditions occur.

Immobilization of the binder because it occurs in the falling rate drying period, there is also a method of lowering the critical moisture content takes longer fixed-rate drying period by reducing the drying temperature.

3-8-1-1.Drying conditions of water-based paint

The ideal paint conditions of the water-based paint are made into 20 ~ 25 ℃ room temperature, and 40 ~ 60RH% humidity.

The ideal paint conditions of solvent base coat, high-solids solvent-based base coat, high solid clear topcoat, such as aqueous basecoat made into 15 ~ 25 ℃ room temperature, and 30 ~ 50RH% humidity.

The ideal paint conditions of solvent-top clear coat are made into 20 ~ 25 ℃ room temperature, and 30 ~ 50RH% humidity.

The ideal paint conditions of the water-base coat has been 15 ~ 25 ℃ room temperature, and 30 ~ 50RH% humidity.

The composition comparative example of the water base coat for cars

| Water | 66% |

|---|---|

| Solvent | 12% |

| Solid | 22% |

<< Dry change of the emulsion water-based paints >>

3-8-1-1.Drying conditions of baking paint

It is the paint method which can dry a paint in a short time (20- 40 minutes).

The polymerization reaction occurs in the coating film by being heated, a dense coating is completed.

The coating film after defined time baking and drying, it will be tough and strong coating film as designed.

It will be the coating fell of performance extremely, if the temperature or time is not enough.

It will be phenomena such as yellowing or low gloss, if the temperature or time is too long or too high.

| Material | Type | Temperature | Time | |

|---|---|---|---|---|

| Melamine | Solvent | 110~160℃ | 20~30min. | |

| Acrylic | Solvent | 140~180℃ | ||

| Urethane | Solvent | 120~140℃ | ||

| Fluorine | Solvent | 160~180℃ | ||

| Silicon | Solvent | 60~80℃ | ||

| Epoxy | Powder | 130~180℃ | ||

| Polyester | Powder | 60~80℃ | ||

3-8-2.Surface smoothness of the paint film

Surface tension of the solvent is nearly constant the entire duration of the drying.

Compressive force caused by the yield stress of the paint film increases in proportion to the progress of drying.

The paint film will shrink at a fixed rate drying period, but the surface is smooth surface tension is maintained.

At the decreasing drying rate period, the yield stress becomes larger than the surface tension, the surface will begin to rough surface of the paint film is compressed.

3-8-3.Thermal expansion of the material

| Material | Coefficient of thermal expansion |

|---|---|

| Carbon steel (S40C) | 11.2 |

| Stainless steel (SUS410) | 10.4 |

| Stainless steel (SUS304) | 17.3 |

| Aluminum (A1050 99.5% purity) | 23.5 |

| Gold | 14.2 |

| Silver | 18.9 |

| Copper | 16.8 |

| Lead | 29.1 |

| Tin | 20 |

| Zinc | 33 |

| Brass | 18~23 |

| Glass | 9 |

| Granite | 8 |

| Brick | 3~9 |

| Wood (fiber direction) | 3~5 |

| (The direction perpendicular to the fibers) wood | 35~60 |

| Polyester | 55~100 |

| Polyethylene | 100~180 |

| Polyvinyl chloride | 70~80 |

| Polystyrene | 60~80 |

| Polycarbonate | 70 |

For example, SUS410 is a millionth of 10.4 with respect to the length.

I will change 10.4μmm if 1m (1000m), material is to 1 ℃ temperature change.

In the case of the acrylic type paint, when baking to 180 ℃ from 20 ℃ room temperature,

L (T) the length of time the temperature T, α the coefficient of thermal expansion,

L(T0+ΔT) = L(T0)(1+αΔT)

It will be in this relationship formula.

In the case of 180 ℃, to 20 ℃, the difference is 160 ℃

L(180) = L(20)*(1+160×10.4×10^-6)=1.001664 L(0)

SUS410 of 1m will 1.664mm expansion.

Aluminum A1050 of 1m will 23.5mm expansion under the same conditions.

In the case of stuck the A1050 and the SUS410,

Especially, the product which fixed steel on the rivet or the screw as reinforcement of aluminum

Processing defect occurs when paint baking.

Such as aluminum will bend by the rivet and screw as the fulcrum, rivet and screw flying, and so on.

To avoid this, it is necessary to incorporate the “long hole” mounting holes, or otherwise absorbs strain.