《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.29 Low temperature aging of electronic parts

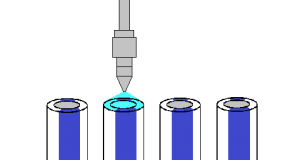

《Problem Point 》 There was no good equipment for in-line low temperature electronic components. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Furthermore, since the set temperature can be maintained with the cool air cooler controller, the product quality ...

Read More »No.28 Evaluation of low temperature operation of semiconductors

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.27 Development of crystal structure of magnetic material

《Problem Point 》 There was no good equipment to pinpoint the magnetic material to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be ...

Read More »No.26 Cold resistance test of color filter

《Problem Point 》 There was no good equipment to cool the color filter. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the Air Cooler Controller, the inspection accuracy has increased.

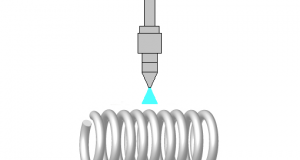

Read More »No.25 Spring coil low temperature deterioration test

《Problem Point 》 There was no good equipment to cool the coil spring. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the Air Cooler Controller, the inspection accuracy has increased.

Read More »No.24 High temperature sensor cooling

《Problem Point 》 With air purging alone, the temperature of the sensor exceeded the specification range, which was a problem. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Temperature drift was suppressed and measurement accuracy was improved.

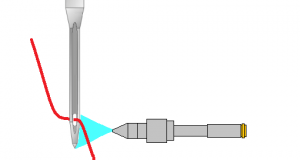

Read More »No.23 Thread trimming prevention by cooling the sewing needle

《Problem Point 》 The sewing thread of the chemical fiber was broken due to the frictional heat and I was in trouble. 《⇒Kaizen Point 》 An Air Blow Cooler was used. MTBF is improved because high-temperature yarn breakage does not ...

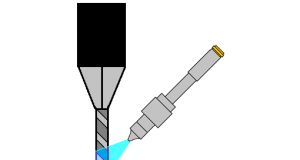

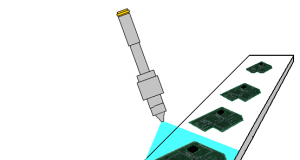

Read More »No.22 Improved quality when cutting resin holes

《Problem Point 》 The resin was fused to the drill due to frictional heat, which was a problem. 《⇒Kaizen Point 》 An Air Blow Cooler was used. The MTBF was improved because the resin did not adhere.

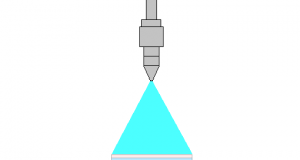

Read More »No.21 Rapid cooling of hot melt

《Problem Point 》 It needed to cool down the hot melt. 《⇒Kaizen Point 》 An Air Blow Cooler was used. It easily came in cool down.

Read More »No.20 Brick pack hot melt cooling

《Problem Point 》 It needed to cool down the hot melt. 《⇒Kaizen Point 》 An Air Blow Cooler was used. It easily came in cool down.

Read More »No.19 Cooling film cutting blade

《Problem Point 》 The resin was fused to the cutting blade due to frictional heat, which was a problem. 《⇒Kaizen Point 》 An Air Blow Cooler was used. The MTBF was improved because the resin did not adhere.

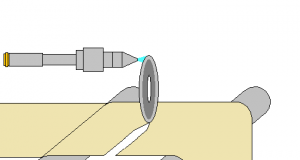

Read More »No.18 Cooling during film fusion sealing

《Problem Point 》 When the film was fused, it was sometimes peeled off due to residual heat. 《⇒Kaizen Point 》 An Air Blow Cooler was used. After thermocompression bonding, it was cooled by removing heat with a Air Blow Cooler. ...

Read More »No.17 Cooling and solidification of resin solvent

《Problem Point 》 There was no good equipment to cool and solidify the resin solvent. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since it can be dried under reduced pressure with cold air, the tact time can be ...

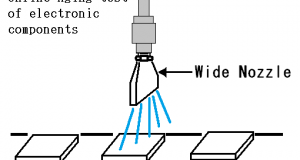

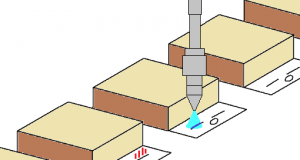

Read More »No.16 Electronic component cooling test

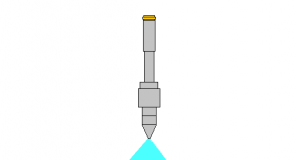

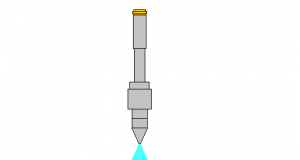

《Problem Point 》 There was no good equipment to pinpoint the electronic component to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be ...

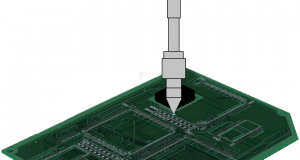

Read More »No.15 Printed circuit board cooling

《Problem Point 》 There was no good equipment to cool the printed circuit board after soldering. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the cool air cooler controller, the tact ...

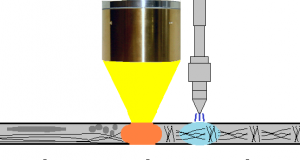

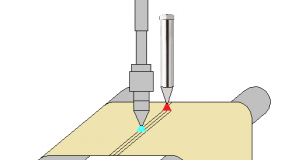

Read More »No.14 Rapid soldering cooling

《Problem Point 》 There was no good equipment to pinpoint the soldering to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

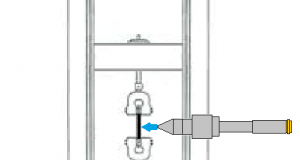

Read More »No.13 Tensile tester low temperature setting

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

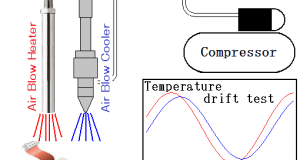

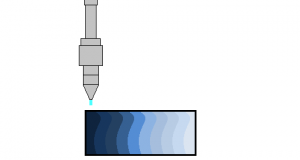

Read More »No.12 Reproduction of thermal distortion

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.11 Cooling and solidification of 3D printer

《Problem Point 》 There was no good equipment to pinpoint the modeling to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

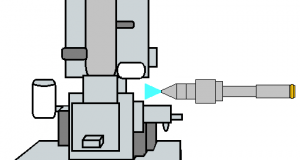

Read More »No.10 Electron microscope sample cooling

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

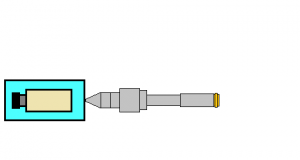

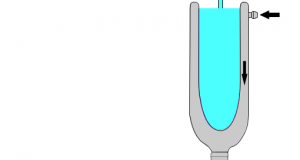

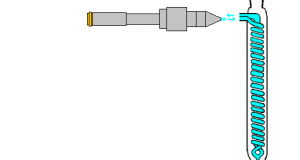

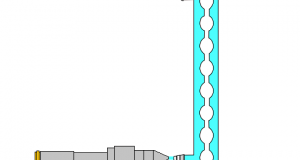

Read More »No.9 Refrigerant of Liebig condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.8 Refrigerant of Dewar condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.7 Refrigerant of Dimroth condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.6 Refrigerant of Allihn condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop