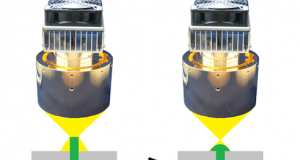

《Problem Point 》 It needed to cool down the hot melt. 《⇒Kaizen Point 》 An Air Blow Cooler was used. It easily came in cool down.

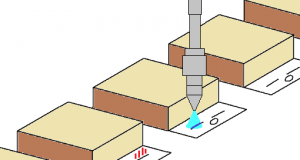

Read More »No.1 Pinpoint heating of resin

[ Problem Point ] There was no compact heater of far infrared which can pinpoint point the resin. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-30. The welding of the resin got to work gently.

Read More »No.56 Heating of high temperature insulation material

[ Problem Point ] The creep characteristic of the high temperature heat insulating material could not be grasped. [ ⇒Kaizen Point ] And heated at high temperature using a halogen line heater. Since it can be heated to any temperature ...

Read More »No.55 Heating of microwave absorbing composite

[ Problem Point ] Microwave absorption characteristics of composite materials under high temperature environments could not be grasped. [ ⇒Kaizen Point ] Heated at high temperature using a halogen line heater. Since it can be heated to an arbitrary temperature ...

Read More »No.20 Promotion of plastic polymerization

[ Problem Point ] We were looking for a heater that can heat steadily without contact. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since temperature control can be done in increments of 1℃, the optimum conditions ...

Read More »No.19 Heat synthesis of proteins

[ Problem Point ] We were looking for a heater that can heat steadily without contact. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since temperature control can be done in increments of 1℃, the optimum conditions ...

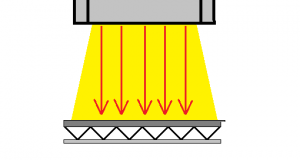

Read More »No.17 Preheating of prepreg

[ Problem Point ] There was no heater which can heat the entire body uniformly. [ ⇒Kaizen Point ] Heated with far infrared panel heater PHX. Since PHX is a panel heater, PHX is able to heat the whole uniformly.

Read More »No.6 Control of a dry time for solvent system adhesive

[ Problem Point ] It took a certain amount of curing at a stable temperature without overshoot. [ ⇒Kaizen Point ] Using the heat retention time control function of highly functional heater controller HHC2. The heating time was tested in ...

Read More »No.5 Heating time control for condition setting

[ Problem Point ] It was necessary to set conditions as to whether heating could be done within the takt time. [ ⇒Kaizen Point ] Using the heat time control function of highly functional heater controller HHC2. The heating time ...

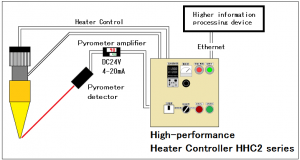

Read More »No.4 Sharing inspection data

[ Problem Point ] Strict operation was required so that the data of the heating inspection can not be overwritten. [ ⇒Kaizen Point ] High performance heater controller HHC 2 equipped with Ethernet communication function, We automatically sent the heating ...

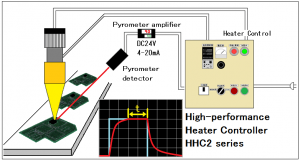

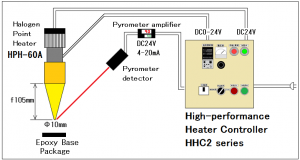

Read More »No.3 Heat dry feedback control of a Epoxy Base package

[ Problem Point ] I intended to shorten the dry time for epoxy base package, but was not able to temperature-control it by non-contact. [ ⇒Kaizen Point ] Thermocontroller for a pyrometer was mounted on the High-performance heater controller HHC2 ...

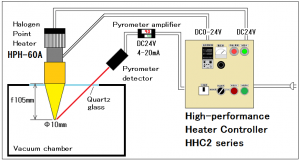

Read More »No.2 Feedback control of the halogen heater for the vacuum chamber heating

[ Problem Point ] I thought I’d like to heat a sample by a linear electron accelerator and an X-ray laser, but percent of vacuum is destroyed, so it isn’t done. [ ⇒Kaizen Point ] Heating was controlled using a ...

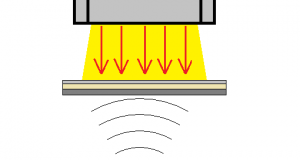

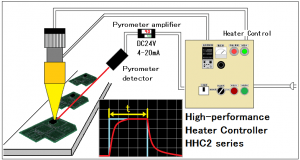

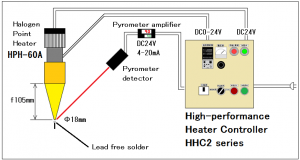

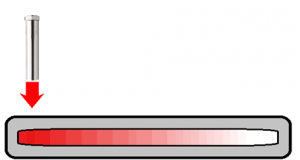

Read More »No.1 Feedback control of halogen heater for solder melting

[ Problem Point ] I thought that I would like to use a halogen heater for the remaining heat of the printed circuit board, but I could not control the temperature without contact. [ ⇒Kaizen Point ] Thermocontroller for a ...

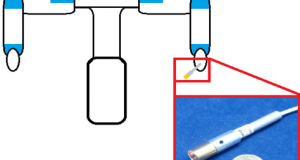

Read More »No.37 Heating processing of the double-arm robot

[ Problem Point ] There was no compact heater that can be mounted on a dual arm robot. [ ⇒Kaizen Point ] It was heated using microminiature Halogen Point Heater HPH-12. Handling became easy since it is a finger size ...

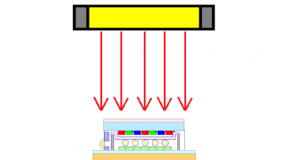

Read More »No.53 Heat test of the color filter

[ Problem Point ] It is necessary to shorten the new development time of a color filter. [ ⇒Kaizen Point ] We were using the parallel light type halogen line heater. Since the halogen heating type, it was able to ...

Read More »No.34 Borosilicate glass tube melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass tube was melted using a halogen point heater. The glass tube processing process was composed only by electric equipment. In addition, ...

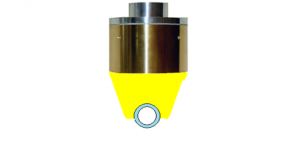

Read More »No.105 Shrink fitting of a small cylinder

[ Problem Point ] Heating equipment that can be used in online was necessary. [ ⇒Kaizen Point ] We ware shrink-fitted by using the Air Blow Heater. The start of the line become faster. Installation because it does not use ...

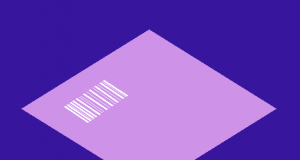

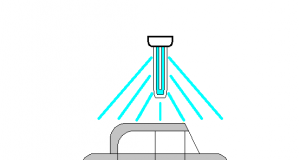

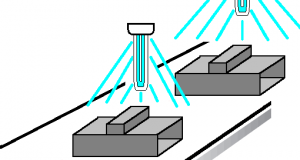

Read More »No.10 Reading of the transparent UV ink

[ Problem Point ] For crisis management, we wanted to print the information on the product. [ ⇒Kaizen Point ] It was printed with UV ink. Since inconspicuous, it finished without changing the package design. Accuracy of crisis management has ...

Read More »No.8 Weather resistance test of painting

[ Problem Point ] We wanted to accelerated test the weather resistance test in the laboratory. [ ⇒Kaizen Point ] It was irradiated with ultraviolet light in the body It is possible to adjust the wattage was take a multi-specific ...

Read More »No.1 Irradiation to ultraviolet curable resin

[ Problem Point ] Shortening the resin hardening time has been required. [ ⇒Kaizen Point ] Curing speed is fast, it was able to shorten the working time. Since no cure and not irradiated with ultraviolet rays, constraints coating process ...

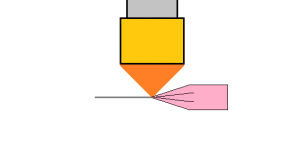

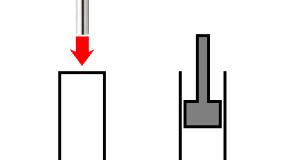

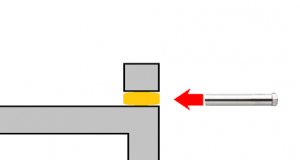

Read More »No.28 Infrared heat caulking of resin boss

[ Problem Point ] Resin adheres to the punch, and this has been a cause of the processing failure. [ ⇒Kaizen Point ] We use tha halogen point heater heating the resin boss. Problem is solved because construction methods that ...

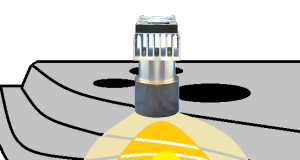

Read More »No.100 Differential temperature inspection of the heat pipe

[ Problem Point ] Good operability heating equipment was needed. [ ⇒Kaizen Point ] We ware heated heat pipe using the Air Blow Heater. It became possible to have multi-point measurement that could not until now. Moreover, since the non-contact ...

Read More »No.98 Drying of the adhesive seal

[ Problem Point ] Shortening of tact time of the adhesive sealing process has been required. [ ⇒Kaizen Point ] We dried seal by the Air Blow Heater. It is the drying time is shortened by a double effect of ...

Read More »No.25 Drying after Precure sealer application

[ Problem Point ] Equipment was big by high-frequency heat and layout change was difficult. [ ⇒Kaizen Point ] Could be simplified mechanism since using the Halogen Point Heater. Teaching for using a halogen light was also easy. Moreover the ...

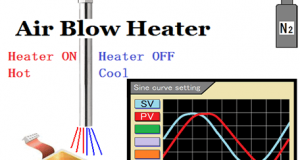

Read More »No.2 Temperature drift test of electronic device by the Air Blow Heater

[ Problem Point ] We have no idea about how to heating and cooling at the same time in line. [ ⇒Kaizen Point ] It made high fever air of a suitable temperature with the Air Blow Heater, projected and ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop