[ Problem Point ] After washing the remaining pickling was in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,it flew in the residual water and heat the air blow was coming out of rust.

Read More »No.56 Two piece feed prevention and preheat of blank material

[ Problem Point ] We were bagged and dried groceries. But there was trouble grows mold. [ ⇒Kaizen Point ] It dried heating nitrogen by the Air Blow Heater. Because nitrogen did not contain water vapor. It became the anti-mold ...

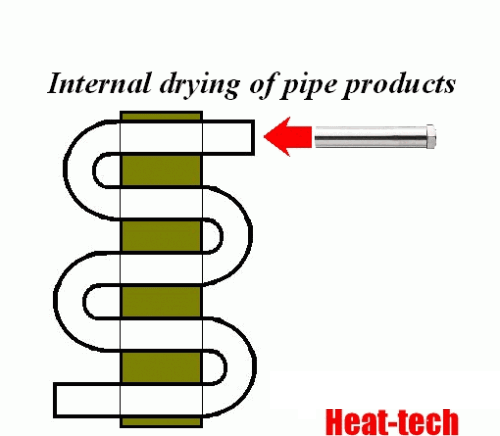

Read More »No.55 Internal drying of pipe products

[ Problem Point ] It was in trouble because Flushing cleaning solution after plumbing processing was left. [ ⇒Kaizen Point ] Rust did not go out because it had dried remaining water by the Air Blow Heater.

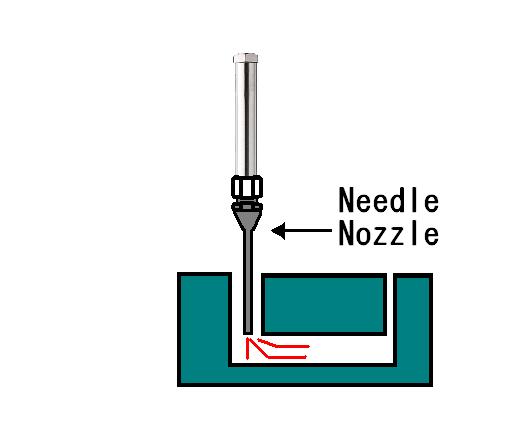

Read More »No.54 Drying of Drilled Hole

[ Problem Point ] When cleaning after cutting chips, water drops were still in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,attached to the needle nozzle,dry blower. Because the hot air blower hot moment, better drying.

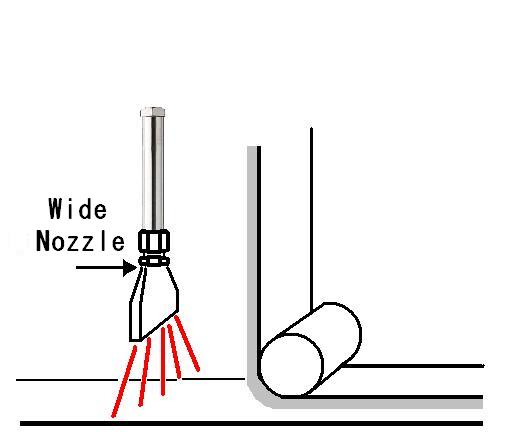

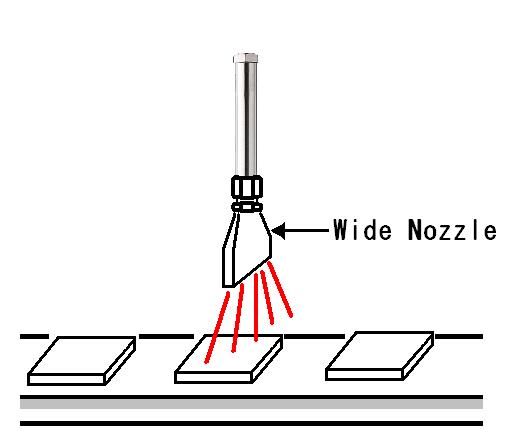

Read More »No.53 Bonding of the film and paper

[ Problem Point ] When the adhesive film and paper,air bubbles were made trouble. [ ⇒Kaizen Point ] Wide nozzle attached to the preheated the Air Blow Heater. To improve the adhesion of air bubbles disappeared.

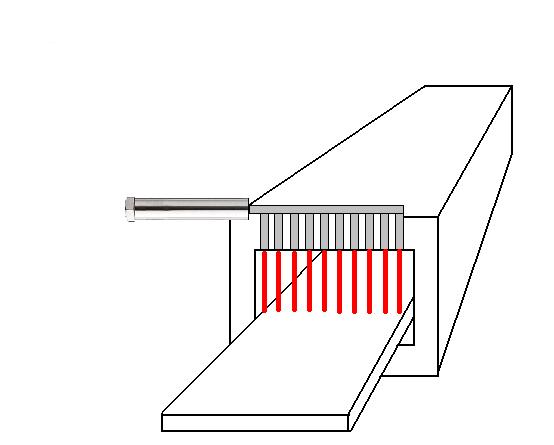

Read More »No.52 Aging of electronic components

[ Problem Point ] It’s being checked by the tester just after the production of electronic components. Control of the heat cycle was difficult. [ ⇒Kaizen Point ] Aging was done with a wide nozzle of the Air Blow Heater. ...

Read More »No.48 Air curtain of furnace

[ Problem Point ] Heat ran away from the furnace,was the problem of quenching quality. [ ⇒Kaizen Point ] The furnace was air sealed with the Air Blow Heater. The temperature of the interior was kept,and the quality of quenching ...

Read More »No.47 Replacement of gas in laboratory electrified

[ Problem Point ] Laboratory has been electrified,the gas was not able to be used and I was in trouble. [ ⇒Kaizen Point ] It was heated by the Air Blow Heater. It was very useful for high temperature heating ...

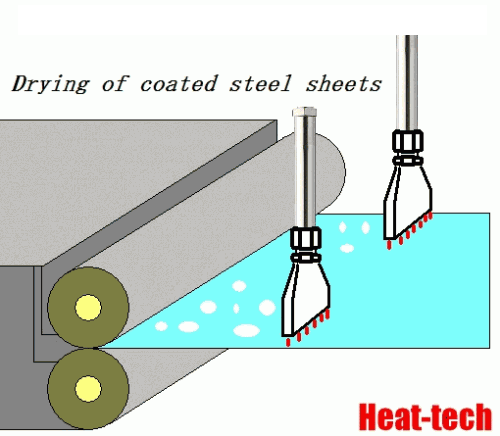

Read More »No.45 Dryness of metal film

[ Problem Point ] The control of the surface tension of a metallic film was difficult when drying with the high temperature gas. [ ⇒Kaizen Point ] It dried using a wide nozzle by the Air Blow Heater. The surface ...

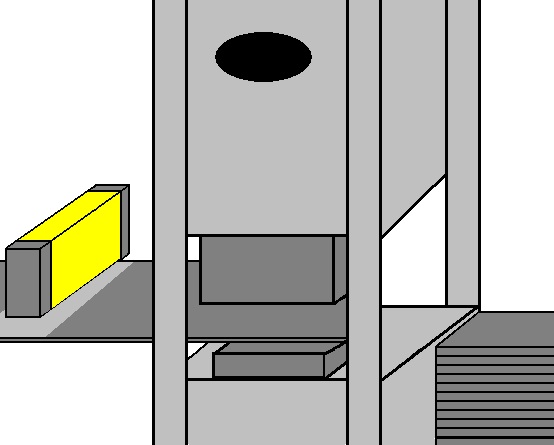

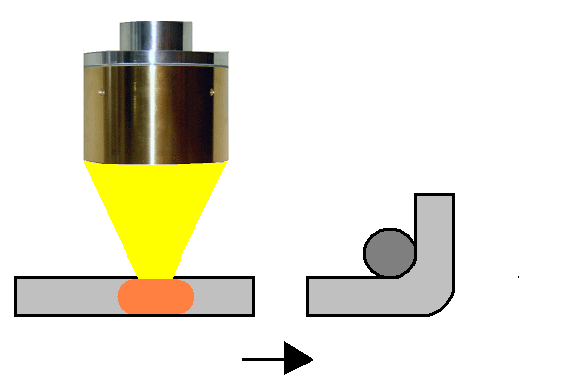

Read More »No.39 Preliminary heating of metal material

[ Problem Point ] We have no way to the drawing press wrinkle. [ ⇒Kaizen Point ] Preheated metal material by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could ...

Read More »No.38 Constant temperature maintenance of metal mold

[ Problem Point ] We have trouble to the die temperature drift for changes in precision finishing. [ ⇒Kaizen Point ] Preheated die by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start ...

Read More »No.41 Dehumidification drying resin pellets

[ Problem Point ] We used the industry dryer. Unable to fine temperature control was a problem. [ ⇒Kaizen Point ] Heated and dried in large type the Air Blow Heater. Dehumidification and sufficient quality of injection molded raised in ...

Read More »No.37 Adjustment of metal stiffening

[ Problem Point ] It is very difficult to annealing temperature control. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater casting surface. Since the maximum temperature heated up in 5sec, immediately after the start of operation could work.The ...

Read More »No.11 Anneal of glass

[ Problem Point ] We have no idea about good annealing of the glass. [ ⇒Kaizen Point ] Warming by the Ir Panel Heater. Glass is able to be warmed on the broad wavelength.

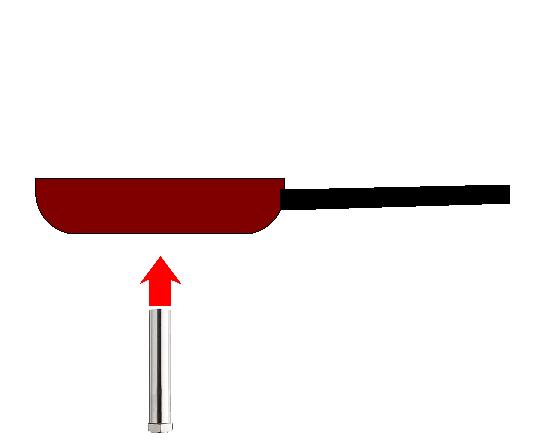

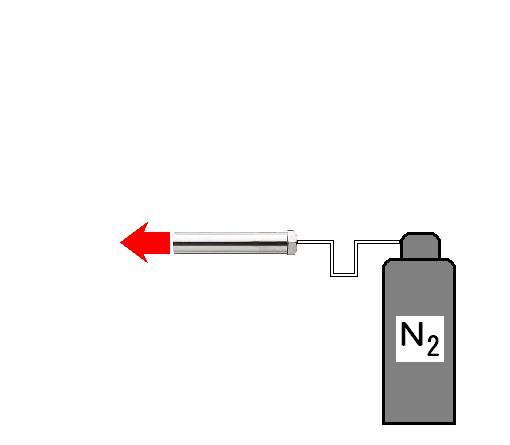

Read More »No.27 Production of hot nitrogen gas

[ Problem Point ] It wasn’t possible to make hot nitrogen gas while keeping the purity. [ ⇒Kaizen Point ] Nitrogen was heated by the Air Blow Heater. Air didn’t get mixed and it was possible to make high temperature ...

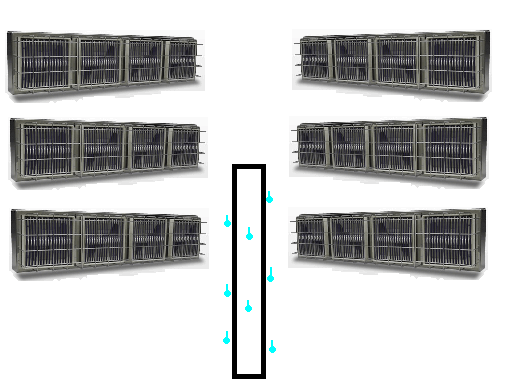

Read More »No.8 Heating unit for drying booth

[ Problem Point ] We have no idea about heating unit for drying booth. [ ⇒Kaizen Point ] Drying by the Ir Panel Heater. Since rapid heat up on drying booth,increased uptime. Now able to respond flexibly to unexpected interrupt ...

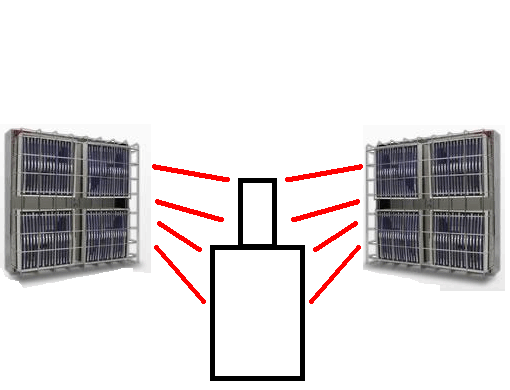

Read More »No.7 Curing of the epoxy resin

[ Problem Point ] We have no idea about curing of the epoxy resin. [ ⇒Kaizen Point ] Curing by the Ir Panel Heater. Since rapid curing, increased uptime. Now able to respond flexibly to unexpected interrupt work.

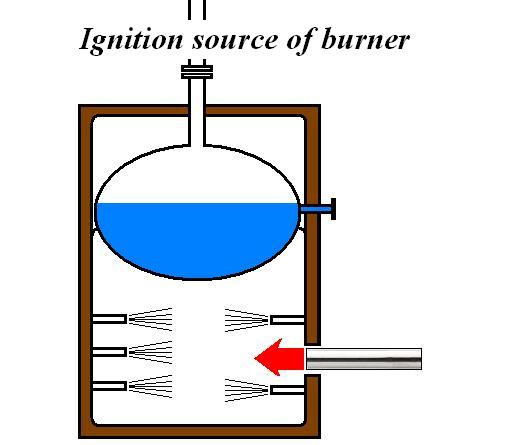

Read More »No.23 Ignition source of burner

[ Problem Point ] We were in trouble because there were no small ignition sources. [ ⇒Kaizen Point ] The Air Blow Heater ignited heated to high temperature.

Read More »No.20 Repair of resin mold

[ Problem Point ] A few bruises were the claim, and we were in trouble. [ ⇒Kaizen Point ] It was heated lightly by the Air Blow Heater,and the luster of the surface was taken good.

Read More »No.19 Recovery of resin mold

[ Problem Point ] We were in trouble because there were no deburring methods of a resin mold. [ ⇒Kaizen Point ] An abuse moth just applied hot air lightly by the Air Blow Heater, and went off easily. Yield ...

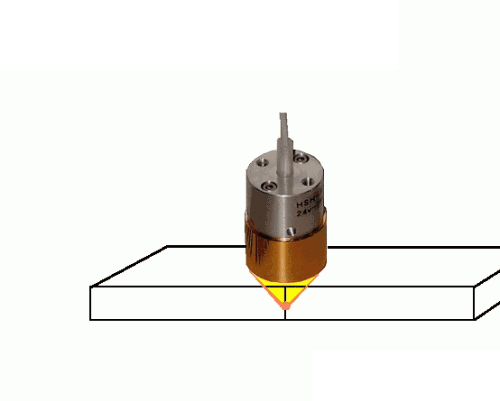

Read More »No.14 Plastic resin welding

[ Problem Point ] It was no easy way to trouble-free welding without oxygen. [ ⇒Kaizen Point ] Welded by the small point halogen heater. Easily welded in nitrogen atmosphere. Junction with improved quality.

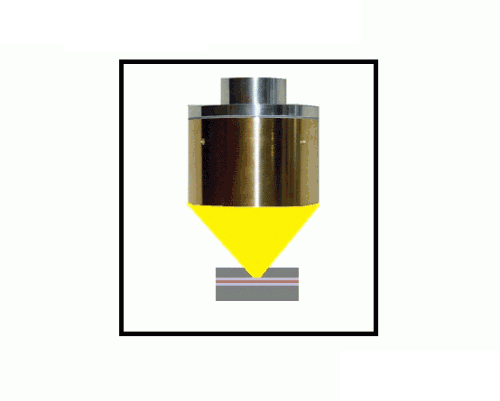

Read More »No.13 Forming of the multilayer polymer film

[ Problem Point ] There was no heater can heat to penetrate the polymer film on the upper side metallic mold. [ ⇒Kaizen Point ] We use the Halogen Point Heater Because the halogen point was heated to pinpoint the ...

Read More »No.11 Preheating of bending work

[ Problem Point ] The crack happened and very troubled. [ ⇒Kaizen Point ] The pipe preheated with the Halogen Point Heater. The surface tensity was removed because it heated at the suitable temperature and the crack disappeared.

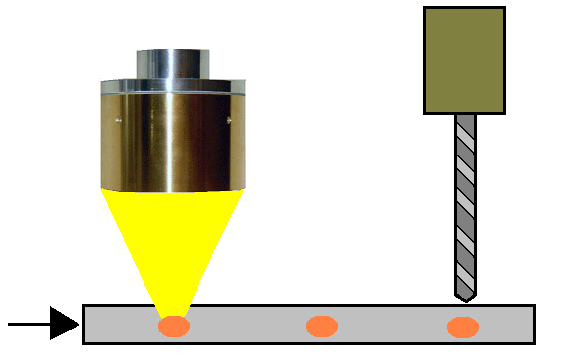

Read More »No.14 Dryness of electro-resistance-welded tube

[ Problem Point ] We were in trouble because there was no space where BLOWER which transfers cooling water after the back weld pulled out is installed. [ ⇒Kaizen Point ] It was dried at high temperature by the Power ...

Read More »No.10 Removal of the surface tension of the pipe hole drilling

[ Problem Point ] The hole crack happened and very troubled. [ ⇒Kaizen Point ] The pipe preheated with the Halogen Point Heater. The surface tensity was removed because it heated at the suitable temperature and the crack disappeared.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop