[ Problem Point ] When the baking color was put,the smell of the gas shifted,so we were in trouble about gas. [ ⇒Kaizen Point ] A spot was heated by the Air Blow Heater. and the baking color was put. ...

Read More »No.20 Dryness of rubber after bonding

[ Problem Point ] Installation space is narrow,we have no idea about long length small and strong heater. [ ⇒Kaizen Point ] Preheated by the Halogen Line Heater in front and back. The product fineness has improved because the temperature ...

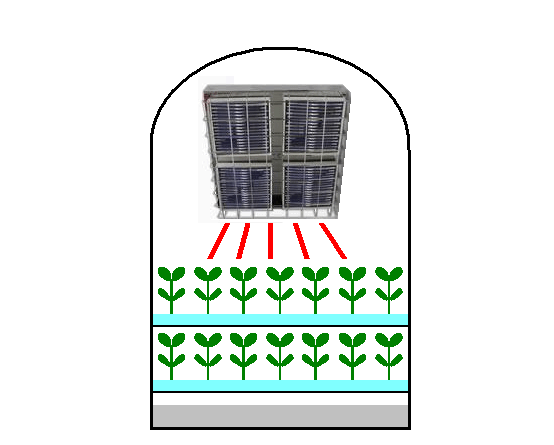

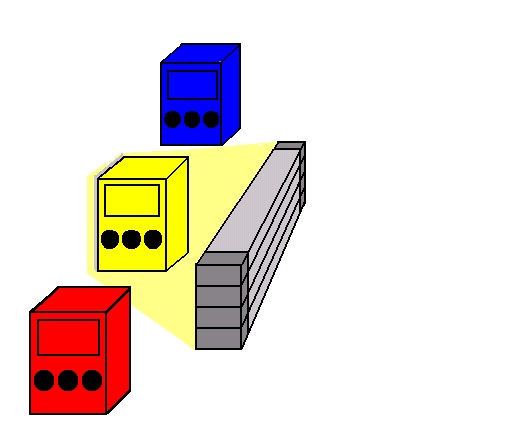

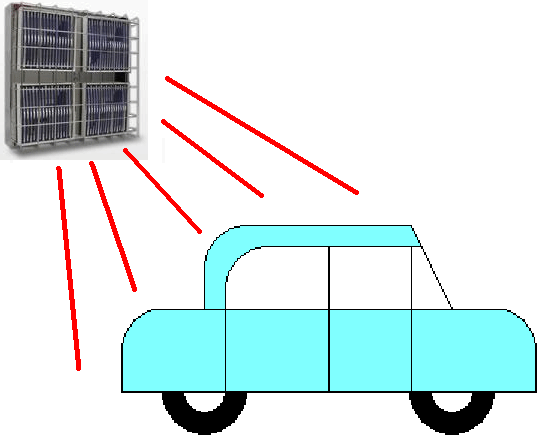

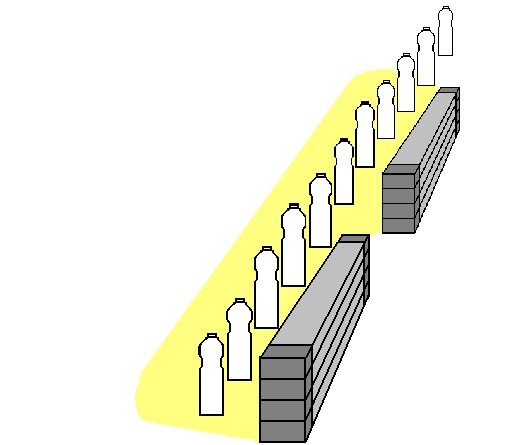

Read More »No.6 Growth and the light source for promoting germination of a plant factory

[ Problem Point ] We have no idea about cost cut of electric. [ ⇒Kaizen Point ] Grown-up ray was illuminated by the Ir Panel Heater. The far-infrared radiation was illuminated at the moment, so power time was finished by ...

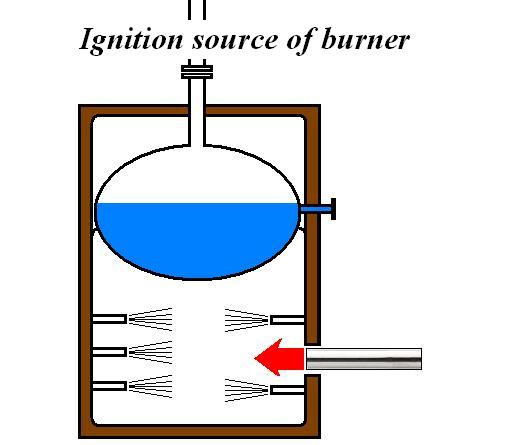

Read More »No.23 Ignition source of burner

[ Problem Point ] We were in trouble because there were no small ignition sources. [ ⇒Kaizen Point ] The Air Blow Heater ignited heated to high temperature.

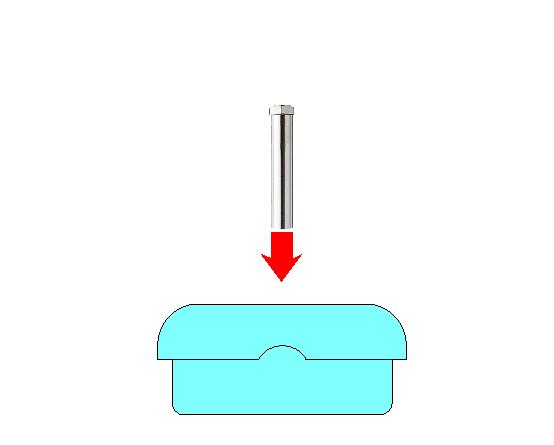

Read More »No.19 Molding preheating of rubber

[ Problem Point ] Installation space is narrow,we have no idea about long length small and strong heater. [ ⇒Kaizen Point ] Preheated by the Halogen Line Heater. The product fineness has improved because the temperature is changed by the ...

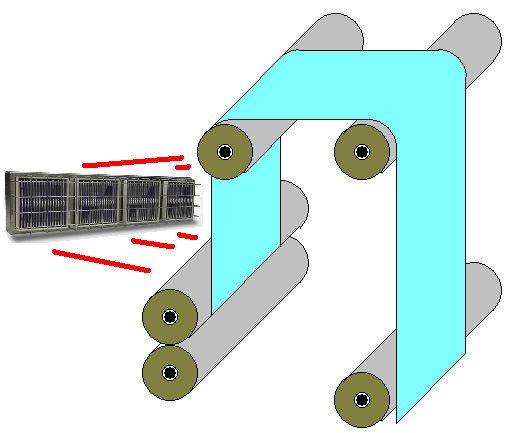

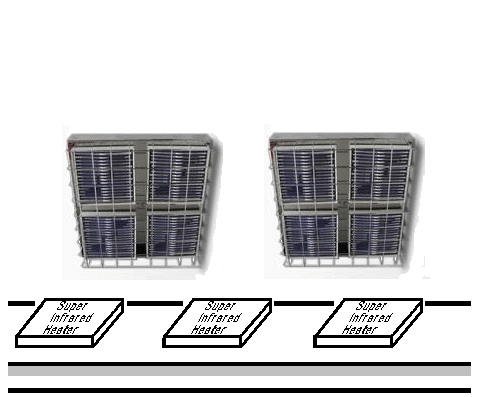

Read More »No.5 Preheat of film

[ Problem Point ] Starting of a drier took time too much.We have no idea about preheat of film. [ ⇒Kaizen Point ] Preheat by the Ir Panel Heater. Since rapid heating, increased uptime. Now able to respond flexibly to ...

Read More »No.22 Electron-microscope sample heating

[ Problem Point ] There was nothing which can be heated hotly in the stand of electron-microscope,and we worried. [ ⇒Kaizen Point ] The spot was heated by the small type of the Air Blow Heater. The precision of the ...

Read More »No.18 Touch-up in consumer electronic repairer place

[ Problem Point ] We have no idea about small and strong quickly heater. [ ⇒Kaizen Point ] The touch-up was dried with the Halogen Line Heater. It was possible to work while preventing the heat damage of other parts ...

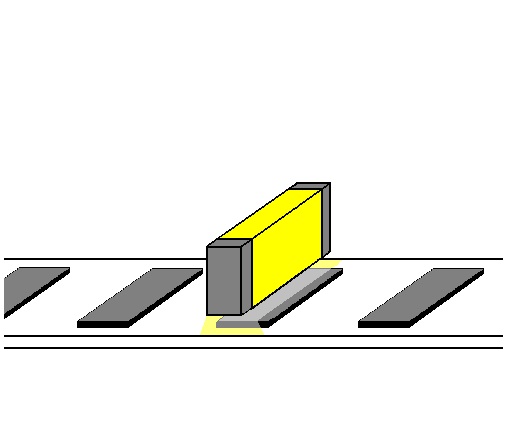

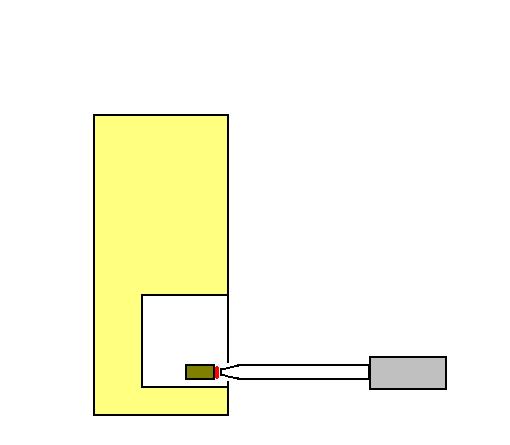

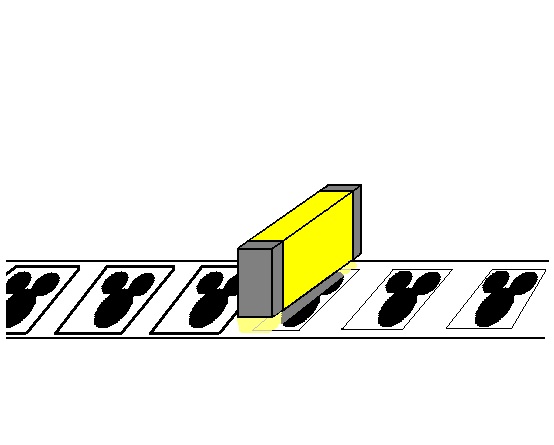

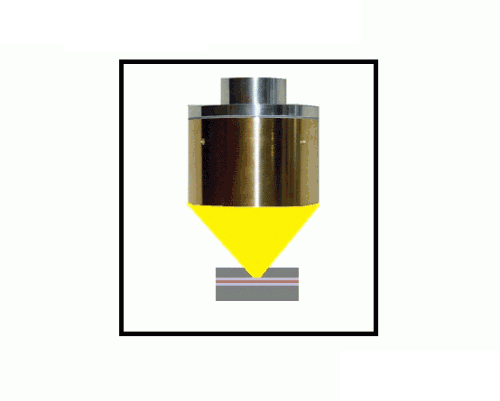

Read More »No.4 Reflow of printed circuit boards

[ Problem Point ] We have no idea about Reflow of printed circuit boards. [ ⇒Kaizen Point ] Reflow by the Ir Panel Heater. Since rapid heating, increased uptime. Now able to respond flexibly to unexpected interrupt work.

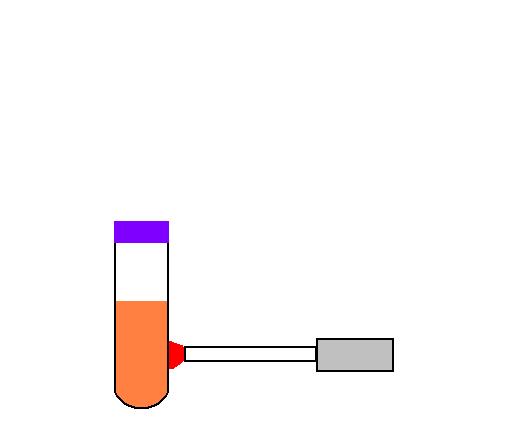

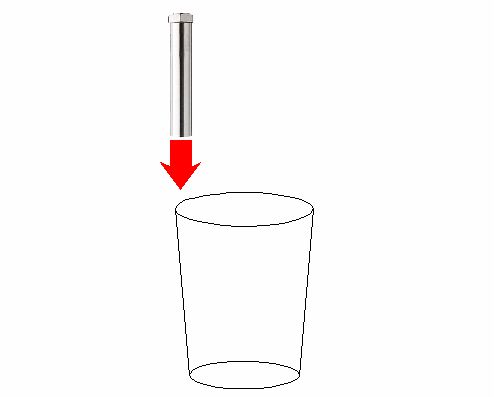

Read More »No.21 Heating of test tubes

[ Problem Point ] We have no idea about how to heating correct temperature control. [ ⇒Kaizen Point ] A spot was heated by the small type of the Air Blow Heater. The experimental precision could experiment with accurate temperature ...

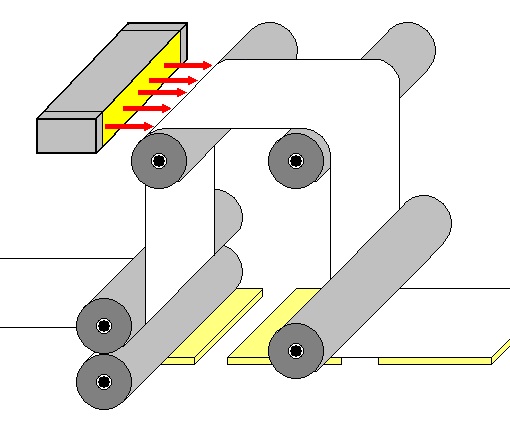

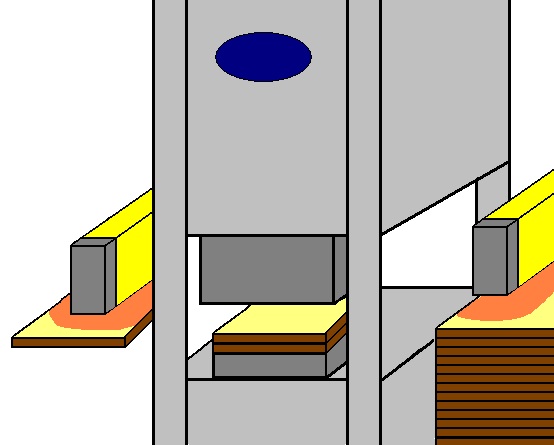

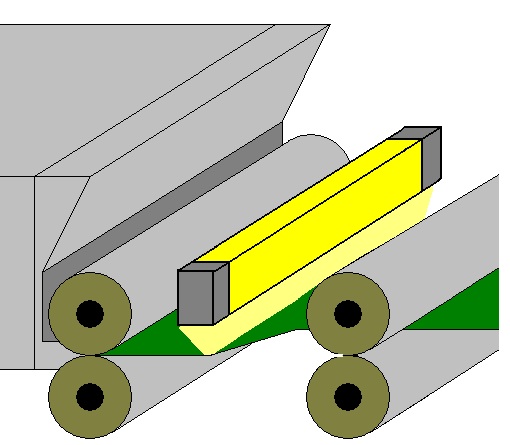

Read More »No.17 Preliminary heating of lamination of plywood

[ Problem Point ] We have no idea about long length small and strong quickly heater. [ ⇒Kaizen Point ] Preheated and dryness by the Halogen Line Heater. The product fineness has improved because the temperature is changed by the ...

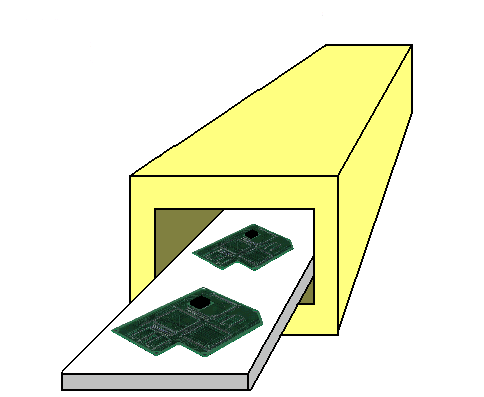

Read More »No.3 Dryness of a silk print

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Dried by the Ir Panel Heater. Since the dryer is heated quickly, no longer waiting time. Now able to respond flexibly to unexpected interrupt ...

Read More »No.20 Repair of resin mold

[ Problem Point ] A few bruises were the claim, and we were in trouble. [ ⇒Kaizen Point ] It was heated lightly by the Air Blow Heater,and the luster of the surface was taken good.

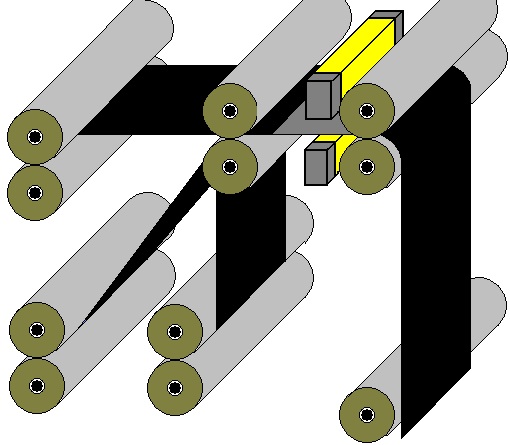

Read More »No.16 Bonding of plywood

[ Problem Point ] We have no idea about long length small and strong quickly heater. [ ⇒Kaizen Point ] Preheated and dryness by the Halogen Line Heater. The product fineness has improved because the temperature is changed by the ...

Read More »No.2 Touch-up dryer

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Dried by the Ir Panel Heater. Since the dryer is heated quickly, no longer waiting time. Now able to respond flexibly to unexpected interrupt ...

Read More »No.19 Recovery of resin mold

[ Problem Point ] We were in trouble because there were no deburring methods of a resin mold. [ ⇒Kaizen Point ] An abuse moth just applied hot air lightly by the Air Blow Heater, and went off easily. Yield ...

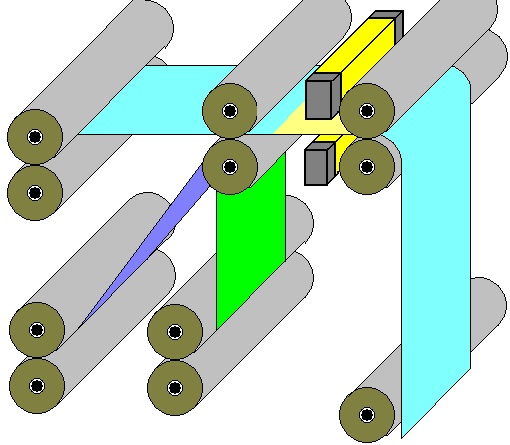

Read More »No.15 Lamination processing

[ Problem Point ] Installation space is narrow,we have no idea about long length small and strong heater. [ ⇒Kaizen Point ] Preheated by the Halogen Line Heater in front and back. The product fineness has improved because the temperature ...

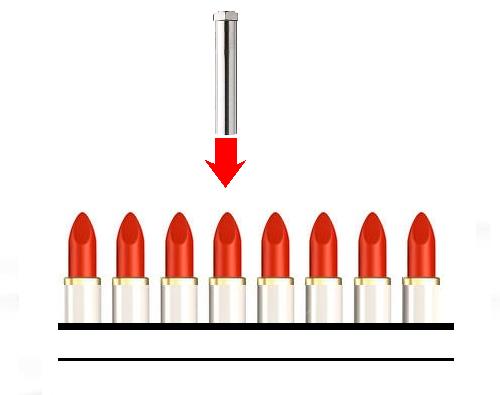

Read More »No.18 Finishing of lipsticks

[ Problem Point ] Even the hit bruise done a little was returned as a defective product, and we were in trouble. [ ⇒Kaizen Point ] The yield which heated a spot by the Air Blow Heater,took on and restored ...

Read More »No.14 Shrink processing

[ Problem Point ] Had trouble to difficult temperature management of the heater. [ ⇒Kaizen Point ] It was heat with the Halogen Line Heater. The product fineness has improved because the temperature is changed by the thickness of the ...

Read More »No.14 Plastic resin welding

[ Problem Point ] It was no easy way to trouble-free welding without oxygen. [ ⇒Kaizen Point ] Welded by the small point halogen heater. Easily welded in nitrogen atmosphere. Junction with improved quality.

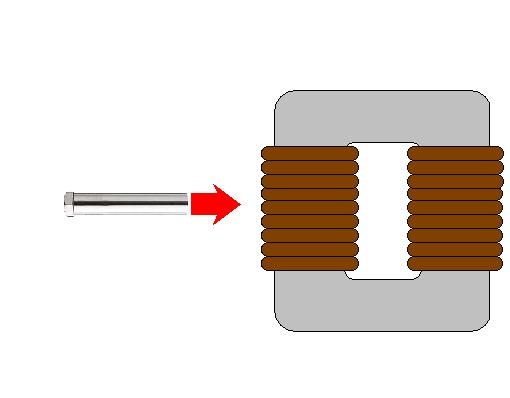

Read More »No.17 Self-bonding wire coil wound

[ Problem Point ] The rolling mark remained in the thin line and we were in trouble. [ ⇒Kaizen Point ] The smooth back into the twisting winding heating the Air Blow Heater Self-bonding caused by heating up the coil ...

Read More »No.13 Heat hardening of resin material

[ Problem Point ] Had trouble to difficult temperature management of the heater. [ ⇒Kaizen Point ] It was heat with the Halogen Line Heater. The product fineness has improved because the temperature is changed by the thickness of the ...

Read More »No.13 Forming of the multilayer polymer film

[ Problem Point ] There was no heater can heat to penetrate the polymer film on the upper side metallic mold. [ ⇒Kaizen Point ] We use the Halogen Point Heater Because the halogen point was heated to pinpoint the ...

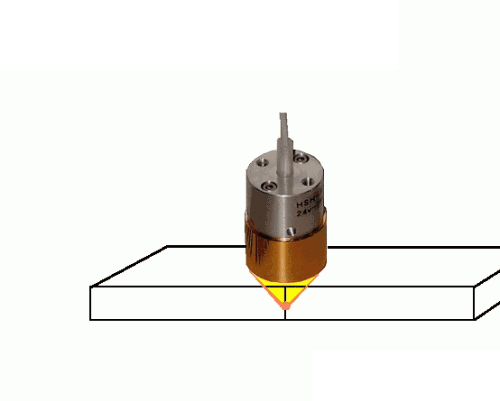

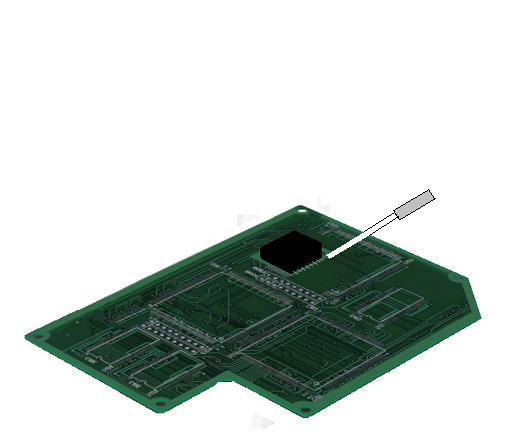

Read More »No.16 Soldering of printed circuit board

[ Problem Point ] We were in trouble because we couldn’t soften cream solder effectively. [ ⇒Kaizen Point ] We have heated the small spot by an extraordinarily small Air Blow Heater and have solved problems.

Read More »No.12 Preheat of blow molding

[ Problem Point ] Had trouble to difficult temperature management of the heater. [ ⇒Kaizen Point ] It was preheat with the Halogen Line Heater. The product fineness has improved because the temperature is changed by the thickness of the ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop