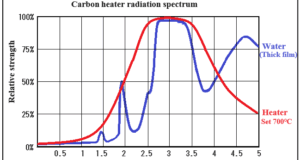

1.Features of CFLH-40 1.Emits mid-infrared rays close to the absorption wavelength of water When the heating element temperature is set to 700°C, the peak wavelength of the radiant energy is approximately 3μm, making it ideal for heating water droplets, aqueous ...

Read More »Overview of the carbon heater

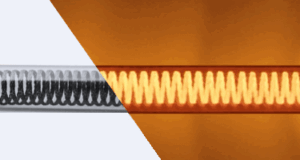

Features of carbon heater 1.Emits mid-infrared rays close to the absorption wavelength of water The peak wavelength of radiant energy is approximately 2~3μm, making it ideal for heating water droplets, aqueous solutions, and other hydrated compounds. 2.Ideal for resin heating ...

Read More »Carbon Heater Price List

Carbon Line Heater CFLH series D/# Mirror Length Volts-Watts Price US$ CFLH-40/PL/L120/220V-400W 120mm 220V-400W US$4,625 CFLH-40/PL/L240/220V-800W 240mm 220V-800W US$5,140 CFLH-40/PL/L320/220V-800W 320mm 220V-800W US$5,650 CFLH-40/PL/L120 (Spare Mirror) 120mm US$4,500 CFLH-40/PL/L240 (Spare Mirror) 240mm US$5,000 CFLH-40/PL/L320 (Spare Mirror) 320mm US$5,500 CFLH-40/L120/220V-400W (Spare ...

Read More »Carbon heater product list

<< Products information>> Overview of the carbon heater << Carbon Line Heater>> Overview of the Carbon Line Heater CFLH-40 series Condensing type Carbon Line Heater CFLH-45 series Parallel beam type Carbon Line Heater CFLH-50 series Best Applications ...

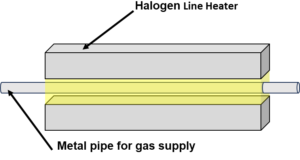

Read More »Melting copper with halogen line heater: Melting process at 1085℃

This video shows copper being heated to its melting point of 1085℃ using a halogen line heater. Please check the following site for more information.

Read More »Pinpoint heating of polypropylene pellets

This video shows pinpoint heating of polypropylene pellets using a halogen glass rod heater. Please check the following site for more information.

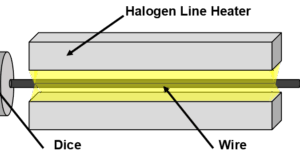

Read More »No.84 Heating in wire drawing process

[ Problem Point ] I was looking for a way to heat wire as a replacement for gas heating. [ ⇒Kaizen Point ] Efficient heating was achieved by installing halogen line heaters opposite each other.

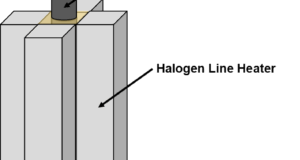

Read More »No.83 High Temperature Corrosion Testing

[ Problem Point ] I was looking for a heater to heat up during high temperature corrosion testing. [ ⇒Kaizen Point ] Halogen line heaters can be heated from four directions and installed vertically. Retrofitting is also possible.

Read More »No.82 High temperature tensile test

[ Problem Point ] I was looking for a way to retrofit a tensile testing machine for high temperature heating. [ ⇒Kaizen Point ] Halogen line heaters can be heated from four directions and installed vertically. Retrofitting is also possible. ...

Read More »Halogen glass rod heater HGRH-70

1. Features of HGRH-70 1) Pinpoint heating is possible. HGRH-70 is a heater that achieves high temperature heating by concentrating the light of a halogen lamp onto a glass rod. The temperature at the tip of the glass rod can ...

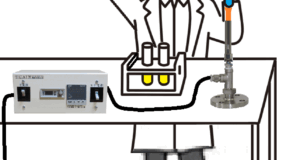

Read More »Air Blow Heater Vertical Stand

The Air Blow Heater can be sprayed vertically. Replaces Bunsen burners. Also available with a stop valve (cock).

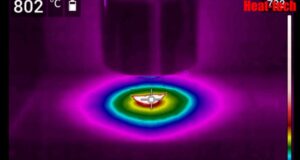

Read More »Heating of an egg shell

This video shows a egg shell being heated to 800℃ using a halogen point heater. Please check the following site for more information.

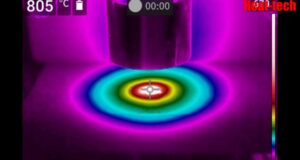

Read More »Heating of a seashell

This video shows a seashell being heated to 800℃ using a halogen point heater. Please check the following site for more information.

Read More »No.81 Heating precursor gas in semiconductor manufacturing process

[ Problem Point ] We were considering heating the precursor gas in order to make the chemical reaction proceed efficiently on the substrate surface. [ ⇒Kaizen Point ] Heating was done by installing halogen line heaters facing each other. Since ...

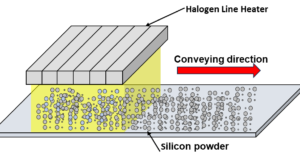

Read More »No.80 Drying of silicon powder in the process of recycling waste liquid discharged from the semiconductor manufacturing process

[ Problem Point ] We were looking for a method to dry silicon powder during the process of recycling waste liquid discharged from polishing silicon wafers in semiconductor manufacturing. [ ⇒Kaizen Point ] Non-contact infrared heating suppresses the scattering of ...

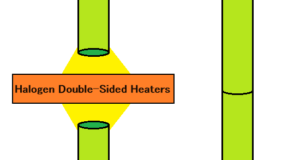

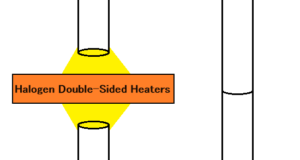

Read More »Double-sided heating of polyester pipe

This is a demonstration of heating a polyester pipe on both sides with the halogen double-sided heater HDSH.

Read More »Double-sided heating of PVC pipe

This is a demonstration of heating a PVC pipe on both sides with the halogen double-sided heater HDSH.

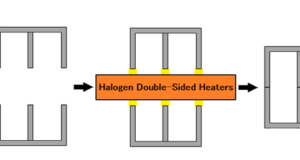

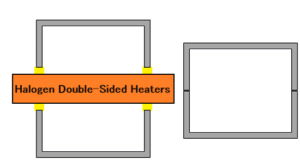

Read More »No.11 Shortening takt time with non-contact hot plate

[ Problem Point ] The challenge was to shorten the tact time of the heat fusion process. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. It uses infrared light to heat and melt without contact. Inline process design ...

Read More »No.10 Heat fusion of resin rods

[ Problem Point ] I wanted to make the weld bead smaller. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs.

Read More »No.9 Heat fusion of resin pipes

[ Problem Point ] I wanted to make the weld bead smaller. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs. Furthermore, because the bonding is done using heat and pressure without using ...

Read More »No.8 Preventing stringiness with non-contact heating plate

[ Problem Point ] I was having trouble with strings and burrs forming on the welded parts. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs.

Read More »No.7 Hermetic welding of thermoplastic resins

[ Problem Point ] A strong weld was required. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Irradiates infrared light to the welded part of two resin parts to heat and melt the resin, After sufficiently melting, the ...

Read More »No.6 Activation of adhesives for reversible fabric processing

[ Problem Point ] I was looking for a slim heater that can be installed by clipping. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. The adhesive applied to the adhesive surface of the fabric was activated, improving ...

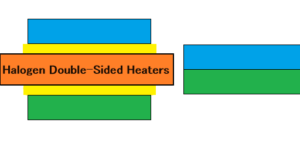

Read More »No.5 Laminating adhesive drying

[ Problem Point ] I was looking for a heater that would heat two sides at the same time during the bonding process. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. By introducing a halogen double-sided heater, we ...

Read More »No.4 Fusion press fitting of resin parts

[ Problem Point ] There was no heater that could heat both sides at the same time. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. The quality has improved because they are heated at the same time. Furthermore, ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop