[ Problem Point ] Resin seat was cut by a blade, it comes loose from the end,and we were in trouble. [ ⇒Kaizen Point ] Hot wind was narrowed down to a pinpoint by the taper type of the Air ...

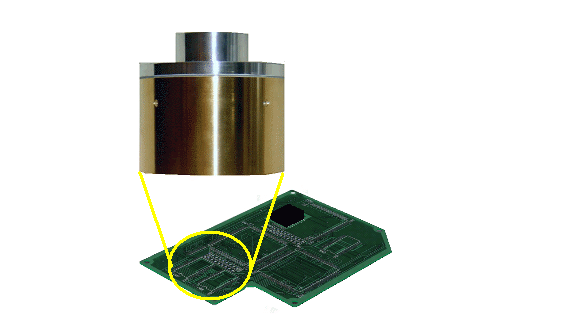

Read More »No.9 Sintering examination of ceramics

[ Problem Point ] We have no idea about good way to easily control and hot quickly. [ ⇒Kaizen Point ] The ceramics was high temperature heated with the Halogen Point Heater small point. The sintering examination went well because ...

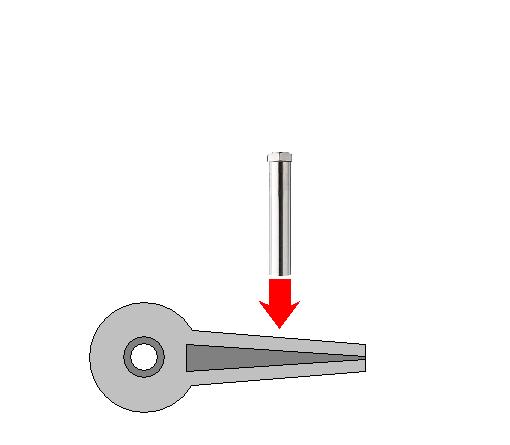

Read More »No.10 Take aluminum Jaggy

[ Problem Point ] Grinder was being used for deburring of aluminum die casting. Hairline can’t leave remaining gloss for the surface. [ ⇒Kaizen Point ] Spot was heated by the Air Blow Heater. and it was deburred. We could ...

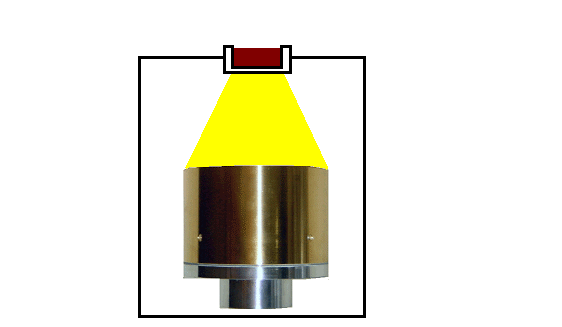

Read More »No.8 Dryness of print

[ Problem Point ] We have no idea about good way to point in the dry heat. [ ⇒Kaizen Point ] Raised the temperature in 15 seconds with the Halogen Point Heater. So clear that the target could prevent heat ...

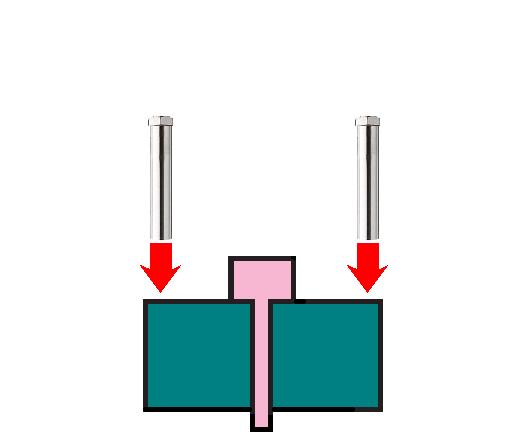

Read More »No.9 Thermal caulking / grilled fit

[ Problem Point ] When baking was put in by gas,control of a rubber gas hose was serious. [ ⇒Kaizen Point ] It was changed so that baking might be put in by the Air Blow Heater. So a process ...

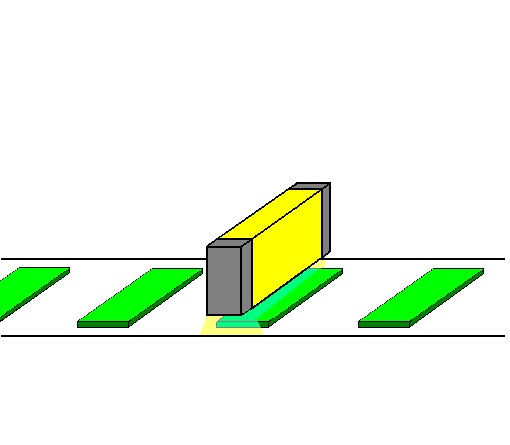

Read More »No.6 Dryness of paints

[ Problem Point ] Had trouble to difficult temperature management of the heater. [ ⇒Kaizen Point ] It was dry with the Halogen Line Heater.The quality has improved because the temperature steady by the voltage regulation was able to manage. ...

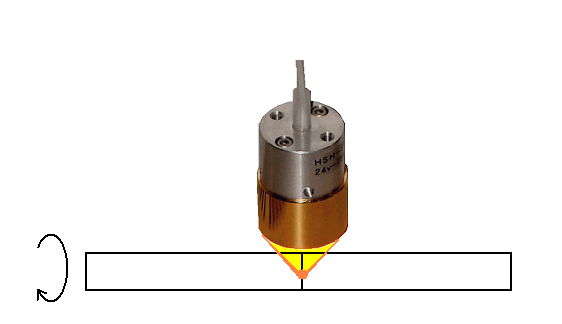

Read More »No.7 Torch of the resin weld

[ Problem Point ] There was nothing good as a torch for resin welds,and we were in trouble. [ ⇒Kaizen Point ] Spot was heated by the Air Blow Heater and resin was welded. The finish could heat a pinpoint, ...

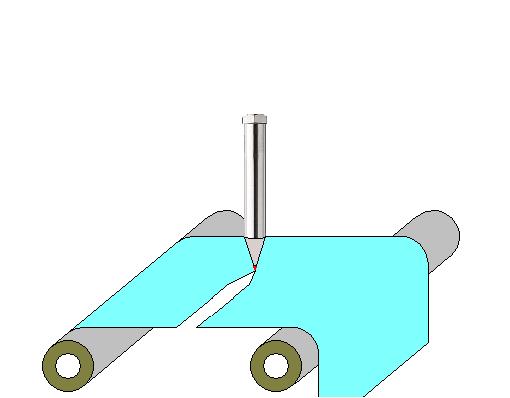

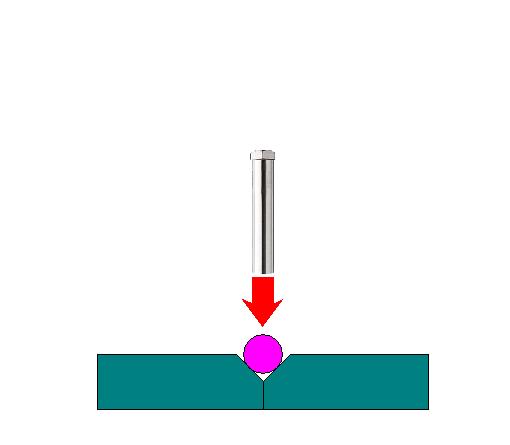

Read More »No.4 Joint of thermoplastic resin tubes

[ Problem Point ] We have no idea about how to joint of thermoplastic resin tubes. [ ⇒Kaizen Point ] The thermoplastic resin tube was joined with the Halogen Point Heater. The heating melt was done, and the central portion ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop