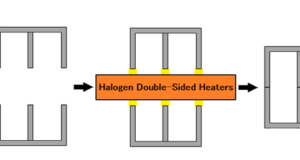

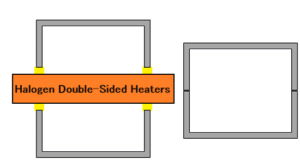

[ Problem Point ] The challenge was to shorten the tact time of the heat fusion process. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. It uses infrared light to heat and melt without contact. Inline process design ...

Read More »No.10 Heat fusion of resin rods

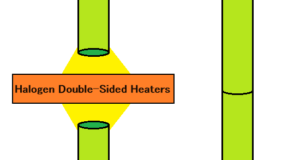

[ Problem Point ] I wanted to make the weld bead smaller. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs.

Read More »No.9 Heat fusion of resin pipes

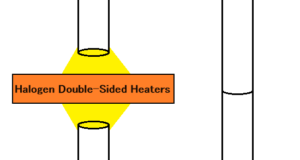

[ Problem Point ] I wanted to make the weld bead smaller. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs. Furthermore, because the bonding is done using heat and pressure without using ...

Read More »No.8 Preventing stringiness with non-contact heating plate

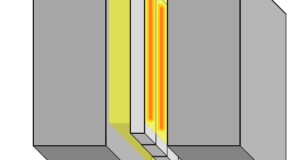

[ Problem Point ] I was having trouble with strings and burrs forming on the welded parts. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Non-contact heating eliminates stringiness and burrs.

Read More »No.7 Hermetic welding of thermoplastic resins

[ Problem Point ] A strong weld was required. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. Irradiates infrared light to the welded part of two resin parts to heat and melt the resin, After sufficiently melting, the ...

Read More »No.6 Activation of adhesives for reversible fabric processing

[ Problem Point ] I was looking for a slim heater that can be installed by clipping. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. The adhesive applied to the adhesive surface of the fabric was activated, improving ...

Read More »No.5 Laminating adhesive drying

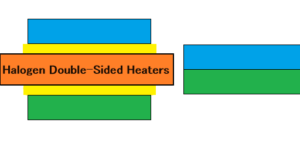

[ Problem Point ] I was looking for a heater that would heat two sides at the same time during the bonding process. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. By introducing a halogen double-sided heater, we ...

Read More »No.4 Fusion press fitting of resin parts

[ Problem Point ] There was no heater that could heat both sides at the same time. [ ⇒Kaizen Point ] Heated with a halogen double-sided heater. The quality has improved because they are heated at the same time. Furthermore, ...

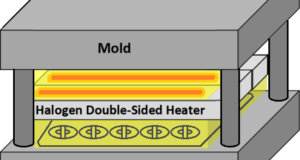

Read More »No.3 Preheating of resin molding mold

[ Problem Point ] To make the mold temperature more stable, it was necessary to preheat the mold before starting the molding cycle. [ ⇒Kaizen Point ] Preheated with a halogen double-sided heater. The waiting time for heating up can ...

Read More »No.2 Preheating aluminum die casting mold

[ Problem Point ] Because the aluminum liquid cools too quickly, its fluidity decreases, leading to problems such as cold cracking, surface shrinkage, dendrites, hot spots, and wrinkles. [ ⇒Kaizen Point ] Preheated with a halogen double-sided heater. Preheating reduced ...

Read More »No.1 Preheating a small press mold

[ Problem Point ] We were looking for a heating method different from gas heating to preheat the mold. [ ⇒Kaizen Point ] Near-infrared heating, which has high heating efficiency for metals, has made it possible to replace gas heating.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop