INDEX

Heat resisting tape with plastic protective PEEK “Toughtape”

“Toughtape” is heat-resistant insulating tape protects the world’s first with PEEK resin.

It was developed for cylindrical lithium-ion battery protection tab 18650.

It could be commercialized successfully developed to withstand high temperature silicone adhesive.

【 Feature 】

PEEK resin exceeds a polyimide material also as insulating tape in electric apparatus or

the semiconductor manufacture field. Water absorption coefficient is low and the electrical

characteristics by the high frequeney range are good, and PEEK is durable resin.

Moreover, we improved the conventional heat-resistant tape.

- Water-resistance and Steam-proof

- Radiation resistance

- Alkali fastness

【 The use 】

◎Electric equipment

Cylindrical lithium-ion battery protection tab 18650

Temporary fixing of aging heat and cycle test examination process

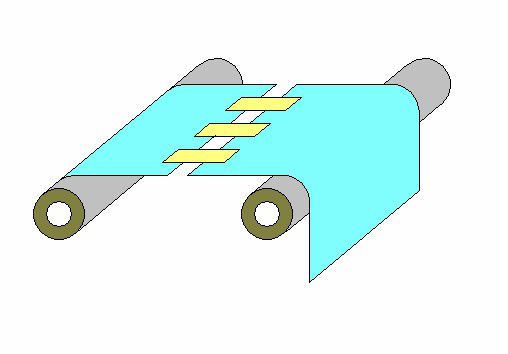

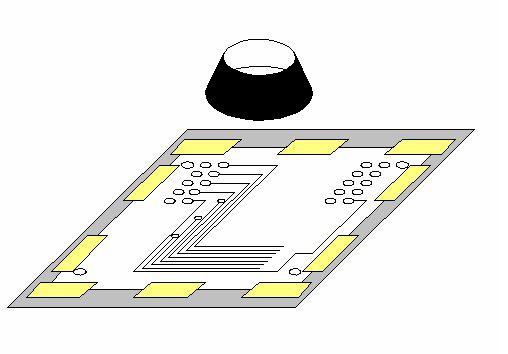

Flow and reflow soldering process for printed circuit board, masking the Gold Plate Contact

Flow and reflow soldering process for printed circuit board through-hole mask

Insulation of electrical equipment (Class H resistant)

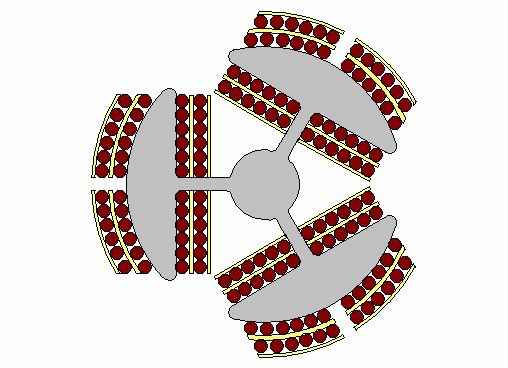

Motor and Transformer interlayer insulation

Outer stop winding and interlayer insulating transformers and coils

Wire bond, Since the adhesive force is stable even after heating.

◎Car equipment

Car paint protection

Wire bond, Since the adhesive force is stable even after heating.

Solidarity and splices that require tensile bond strength

◎Chemical products

For applications requiring heat resistance and solvent resistance

Temporary closure near the hotspot

Splicing and connecting the film

End surface of the film take-up fixed

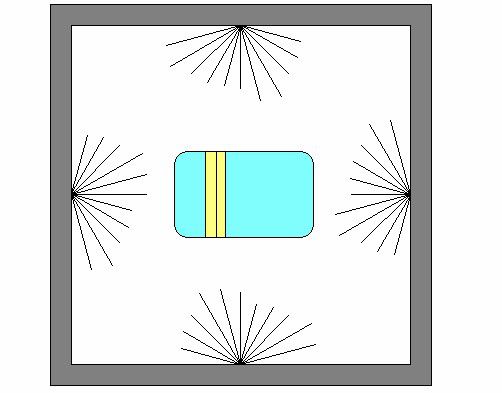

Attachment of film or mask at the exposure and printing.

Packaging requires a tensile strength of adhesion

◎Food processing

PEEK resin is adapted to the Food Sanitation Law of Japan.

PEEK resin is less sure hygroscopic material is resistant to steam.

Temporarily attach in the process of steam sterilization

Packaging requires a tensile strength of adhesion

【 Specification 】

D/#:TM-HT-25

Colour:Semitransparent

Thickness:45μm

Base:25μm

Width:25mm

Length:10m

Normal use:260℃

Base resin:PEEK

Adhesives:Silicon-based

Price:JPY10,000.-

“Toughtape” is, PI (polyimide) tape compared to the chemical resistance, tear strength, low water absorption, excellent barrier properties, also, PTFE (polytetrafluoroethylene PTFE /) compared to the mechanical properties abrasion resistance, dielectric strength, releasing toxic gases and low smoke evolution, low permeability, low exhibit characteristics such as low specific gravity.

Moreover, since it has the high heat resistance required of lead-free soldering processing, the use as a masking material in an electric electronic use is also possible.

Furthermore, VICTREX PEEK which is the raw material of APTIV Films, While demonstrating UL94 V-0 fire retardancy, without using the FDA approval and halogen system fire retardant, it is a thermoplastic material which can recycle and is based on RoHS Directive, and conforms to many standards and standards relevant to aerospace, a car, combustion, emitting smoke, toxicity, food/drinking water, or military affairs.

【 What is PEEK ? 】

PEEK is the formal name for ISO1043 showing polyetheretherketone (Poly Ether Ether Ketone).

English ICI (Imperial Chemical Industries ) developed PEEK resin. It was announced in 1978 and put on the market in 1981.

Victrex was separated from the PEEK operation division of ICI by MBO in 1993. Present Victrex (head office: British Lancashire state) is a development maker even now. It manufactures and sells and the “Toughtape” adopted APTIV Films of Victrex by the first in the world.

The advantage of PEEK made from VICTREX

- Preeminent heat resistance, the high temperature characteristic.

(Continuous use temperature of about 260 ℃) - Demonstrate Low Coefficient of Friction and High Wear Resistance, without Using Lubricant.

- High mechanical strength. (It is strong to a shock, tension, creep, fatigue, and wear)

- Load Bending Temperature is about 140 ℃.

- Not only excelling in fatigue resistance but wear and abrasion resistance and dimensional stability are also good.

- Insoluble in Solvent with Outstanding Solubility-proof with Acid, Base, Common Oil, Etc.

- Chemical resistance is also excellent and it is not invaded by the inorganic matter and an organic medicine except strong sulfuric acid, dark nitric acid, and saturation chlorine water.

- It has the fire retardancy of UL94V-0 in the state where property modification is not carried out.

- Since High Purity [ in Low Out Gas and Low Dust], Contamination Generating is Reduced, and it Has Electrical Insulation Properties.

- Steam-proof Nature (Hydrolysis is not Caused under High Temperature Vapor)

- Radiation Resistance (Degradation by Radiation Does Not Take Place Easily)

- Outstanding electrical insulation properties.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop