[ Problem Point ] There was nothing that could heat the dummy gas at any temperature. [ ⇒Kaizen Point ] A air blow heater was used. Since there is a controller that can automatically control the temperature and hot air ...

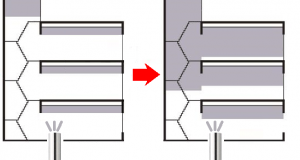

Read More »No.113 Activated carbon regeneration

[ Problem Point ] There was no device that was small and could be inlined. [ ⇒Kaizen Point ] Using hot air heater environment resistant type DGH series, Heated steam was blown into the activated carbon. The accumulated dirt was ...

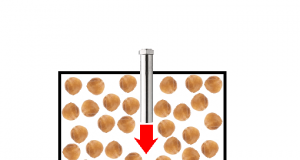

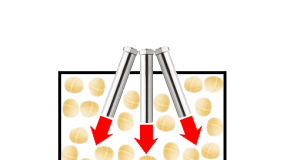

Read More »No.112 Hot air roasting of Hazelnuts

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control around 160℃ can be easily done in 1℃ increments. Moreover, since ...

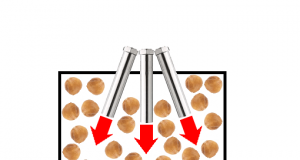

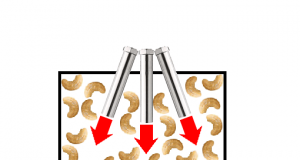

Read More »No.111 Hot air roasting of Cashew nuts

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control in the 150℃. band and the 230℃ band, can be easily ...

Read More »No.110 Hot air roasting of Macadamia nuts

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. From light roasting 140℃ to dark roasting 170℃, can be easily done in 1℃ ...

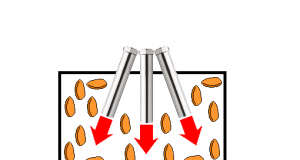

Read More »No.109 Hot air roasting of Peanuts

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control around 180℃ can be easily done in 1℃ increments. Moreover, since ...

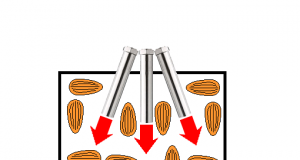

Read More »No.108 Hot air roasting of Almond nuts

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control around 150℃ can be easily done in 1℃ increments. Moreover, since ...

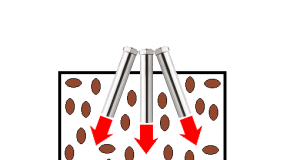

Read More »No.107 Hot air roasting of Cacao beans

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control around from light roasting 120℃ to dark roasting 160℃, can be ...

Read More »No.106 Hot air roasting of Coffee beans

[ Problem Point ] We could not roast uniformly at the optimum temperature up to now. [ ⇒Kaizen Point ] We roasted with Air blow Heaters. Delicate temperature control of roasting at 180℃ for the first time and roast at ...

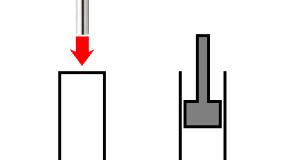

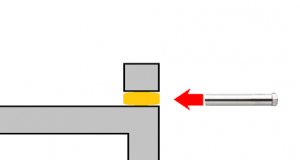

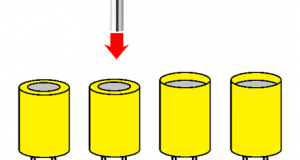

Read More »No.105 Shrink fitting of a small cylinder

[ Problem Point ] Heating equipment that can be used in online was necessary. [ ⇒Kaizen Point ] We ware shrink-fitted by using the Air Blow Heater. The start of the line become faster. Installation because it does not use ...

Read More »No.104 Examination of a engine turbine

[ Problem Point ] Heating equipment of a lean air was needed. [ ⇒Kaizen Point ] Heating the turbine using the Air Blow Heater. Lean air in proportion to the law of Charles was obtained.

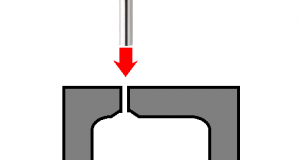

Read More »No.103 Molding of a polyethylene container

[ Problem Point ] The reduction of the defectiveness rate was necessary. [ ⇒Kaizen Point ] We ware molded using the Air Blow Heater. Since the heating air fluidity of the resin is improved.

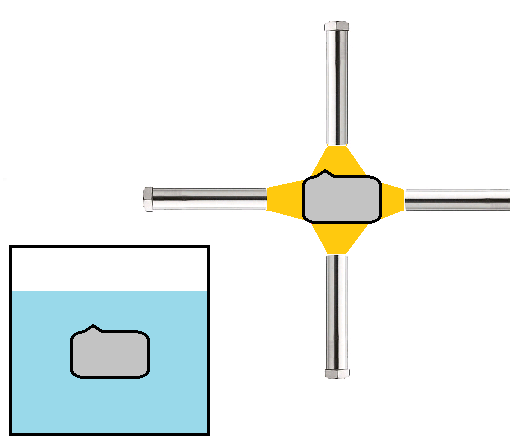

Read More »No.102 Drying after the leak test using a water tank

[ Problem Point ] Shortening of the dry time was necessary. [ ⇒Kaizen Point ] We ware heated to work by using the Air Blow Heater. Dry time became short more markedly than air blow drying. Installation because it does ...

Read More »No.101 Adhesion of PVC sheet

[ Problem Point ] The exact temperature control was necessary. [ ⇒Kaizen Point ] We adhered to PVC sheet using the Air Blow Heater. Rise early, it has allowed accurate temperature control. Besides, it became the maintenance-free as Air Blow ...

Read More »No.100 Differential temperature inspection of the heat pipe

[ Problem Point ] Good operability heating equipment was needed. [ ⇒Kaizen Point ] We ware heated heat pipe using the Air Blow Heater. It became possible to have multi-point measurement that could not until now. Moreover, since the non-contact ...

Read More »No.99 Culture of anaerobic microorganisms

[ Problem Point ] It could not be freely temperature change Dummy-gas. [ ⇒Kaizen Point ] We use the Air Blow Heater DGH series for environmental, We made dummy gas change the temperature freely, and a cultivation test of an ...

Read More »No.98 Drying of the adhesive seal

[ Problem Point ] Shortening of tact time of the adhesive sealing process has been required. [ ⇒Kaizen Point ] We dried seal by the Air Blow Heater. It is the drying time is shortened by a double effect of ...

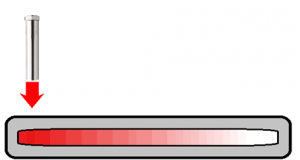

Read More »No.97 Temperature performance evaluation test of the rechargeable battery

[ Problem Point ] The advanced battery with environment resistance is required for. [ ⇒Kaizen Point ] The temperature test was done using the Air Blow Heater. The rapid temperature change which was impossible until now has been reproduced. The ...

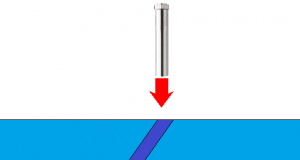

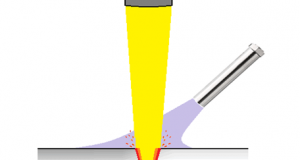

Read More »No.96 Heating of the shielding gas of laser welding

[ Problem Point ] Oxide film on the weld surface is worried about. [ ⇒Kaizen Point ] High temperature heating of the shielding gas was carried out using the hot wind heater. Even if it thickened metal, welding said well.

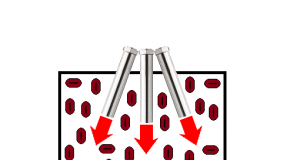

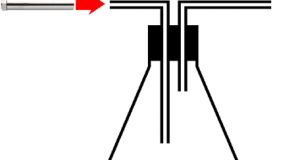

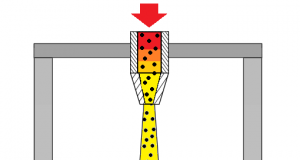

Read More »No.95 Hot air shot peening

[ Problem Point ] In order to thicken a metallic thin film, the high temperature hot wind was required. [ ⇒Kaizen Point ] The shot-peened under high temperature conditions using the Air Blow Heater. Junction went well even if thickening ...

Read More »No.94 Hot air anthelmintic

[ Problem Point ] Requires secure chemical-free pest control that do not use chemical fumigation. [ ⇒Kaizen Point ] Hot air is anthelmintic, in a way that does not use chemicals, to disinfect from egg to adult in a hot-air, ...

Read More »No.93 Heat shrink the capacitor

[ Problem Point ] It did not shrink processed while temperature control. [ ⇒Kaizen Point ] The precise temperature control in the Air Blow heater, it was appropriate temperature heating. Thermal destruction is eliminated, defect rate was reduced.

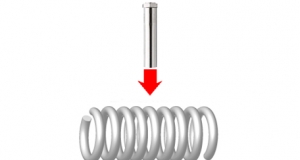

Read More »No.92 Temperature setting of the coil spring testing machine (low-temperature material)

[ Problem Point ] There was no evaluate the performance while changing the temperature of the coil springs. [ ⇒Kaizen Point ] It heated from room temperature to 850℃ with the Air blow heater. The quality assessment in the arbitrary ...

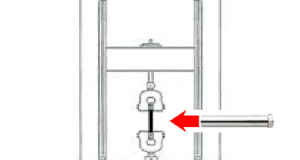

Read More »No.91 Temperature setting of the tensile testing machine (low-temperature material)

[ Problem Point ] There was no evaluate the performance while changing the temperature of the test piece. [ ⇒Kaizen Point ] It heated from room temperature to 850℃ with the Air blow heater. The quality assessment in the arbitrary ...

Read More »No.90 Heat test of bearing

[ Problem Point ] Managing the heat-resistant temperature of grease, it came to carry out a quality assessment and there was nothing. [ ⇒Kaizen Point ] It heated from room temperature to 550℃ with the Air blow heater. The quality ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop