INDEX

Various factors contribute to errors in temperature measurement, but among them, incomplete thermal contact, time delay, and environmental influences are the primary causes of measurement inaccuracies.

These errors can be minimized by adopting appropriate measurement methods and environmental adjustments. In this chapter, we will integrate the causes of these errors with practical countermeasures and provide a detailed, hands-on approach.

3.1 Errors Due to Incomplete Thermal Contact and Their Countermeasures

3.1.1 Causes of Thermal Contact Errors

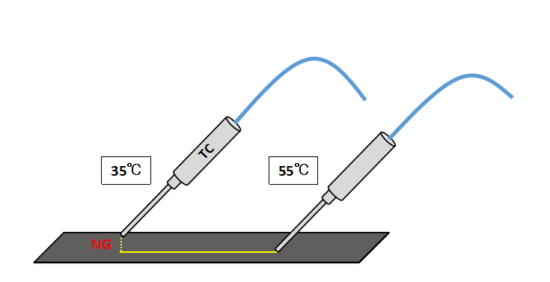

In temperature measurement, if the sensor’s sensing part is not in proper contact with the measurement target, accurate temperature readings cannot be obtained. This issue is particularly significant when using contact-type temperature sensors such as thermistors, resistance temperature detectors (RTDs), and thermocouples. The primary causes of error include:

Small contact area

Insufficient heat transfer leads to a measured temperature lower than the actual temperature.

Floating temperature sensor

The sensor does not thermally stabilize with the measurement target, making it susceptible to external environmental influences.

Intervening high-insulation layer (oxidized film or air gap)

Heat transfer is obstructed, preventing accurate measurement.

3.1.2 Effective Countermeasures

To prevent errors caused by incomplete thermal contact, the following measures are effective:

1. Enhance contact between the sensing part and the target

Maximize the contact area between the sensor and the target.

Use heat-resistant tape to stabilize the temperature sensor

2.Utilize materials that improve thermal conductivity

Apply silicone grease or thermal paste to enhance heat conduction between the sensing part and the measurement target.

This is particularly effective when measuring materials with low thermal conductivity, such as plastic or ceramics.

3. Minimize the influence of air gaps

Embed the sensing part inside the measurement target to reduce external environmental impact.

When measuring surface temperatures, insert a low-insulation sheet to minimize the effects of air layers.

3.2 Errors Due to Time Delay and Their Countermeasures

3.2.1 Causes of Time Delay Errors

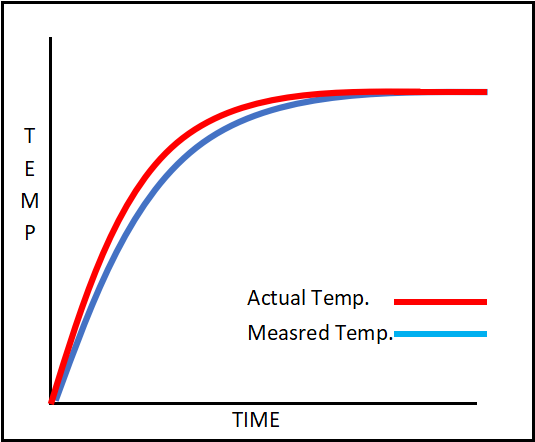

In environments with rapidly changing temperatures, the sensor’s response may lag, causing a delayed measurement relative to the actual temperature. The primary factors contributing to this error are:

High thermal capacity of the temperature sensor

The sensor accumulates heat, making it slow to respond to temperature changes.

Impact of protective tubing

In high-temperature environments, the sensor’s protective tube absorbs heat, delaying the sensor’s response to actual temperature changes.

Slow display update speed of the temperature controller

Even if the sensor accurately detects temperature, a slow update speed on the temperature controller display can prevent real-time monitoring of temperature changes.

Since time delay errors are mainly caused by sensor characteristics, the responsiveness of measurement devices, and the effects of protective tubes, selecting the appropriate sensors and instruments based on measurement objectives and environmental conditions is crucial.

3.2.2 Effective Countermeasures

To reduce errors due to time delay, the following strategies can be applied:

1. Use temperature sensors with fast response times

Select high-speed response sensors such as small thermistors or thermocouples.

2. Optimize measurement methods

Instead of relying on a single measurement, take multiple readings at regular intervals and calculate the average value for improved accuracy.

In environments where rapid temperature fluctuations are expected, use real-time temperature monitoring devices.

3. Implement suitable temperature control devices

Utilize high-speed and high-precision temperature controllers to more accurately track environmental temperature fluctuations.

3.3 Errors Due to Environmental Influences and Their Countermeasures

3.3.1 Causes of Environmental Errors

Temperature measurement is highly susceptible to external environmental factors. Changes in surrounding conditions can significantly impact measurement values. The main environmental factors include:

Effects of wind and airflow

In strong wind conditions, external air can alter the measurement target’s temperature, introducing measurement errors.

Example: In an office or laboratory, taking temperature readings directly exposed to an air conditioner may result in values lower (or higher) than the actual room temperature.

Effects of humidity

In high-humidity environments, condensation may form on the temperature sensor, causing the measured temperature to be lower than the actual value.

Example: In refrigerated warehouses or food processing facilities, condensation on the sensor can lead to measured temperatures that are lower than the actual conditions.

Influence of nearby heat sources

In industrial plants or kitchens, radiant heat from nearby equipment may affect temperature readings.

Example: When measuring the temperature of food during cooking, heat from a gas stove or oven may cause the measured temperature to be higher than the actual value.

3.3.2 Effective Countermeasures

To reduce environmental measurement errors, the following methods are effective:

1. Use wind shields

In outdoor or wind-exposed environments, cover the temperature sensor with a wind shield to prevent direct exposure to airflow.

When measuring outdoors, choose locations sheltered from the wind, such as the shaded side of a building.

2. Select an appropriate measurement location

Ensure sufficient distance from nearby heat sources (heaters, machines, etc.) when conducting measurements.

For room temperature measurement, avoid areas directly affected by air conditioning vents.

3. Consider humidity effects

Apply waterproof coatings to temperature sensors in high-humidity environments to prevent condensation-related errors.

Conduct reference measurements in a dry environment to account for humidity-induced discrepancies.

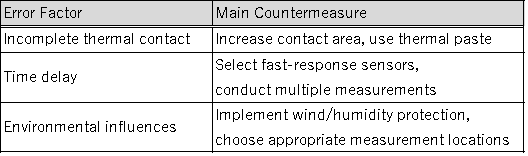

3.4 Summary

The fundamental error factors in temperature measurement include incomplete thermal contact, time delay, and environmental influences. To minimize these errors, the following countermeasures are essential:

By implementing these countermeasures appropriately, more accurate and reliable temperature measurements can be achieved.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop