●Feature of the Small size Air Blow Heater ABH-13A As for the ABH series, heating gas contacts heating element directly. The outer diameter is small, but, by adoption of the big high-density heating element of the surface area that heat ...

Read More »《Ultra-small Air Blow Heater 》ABH-8□

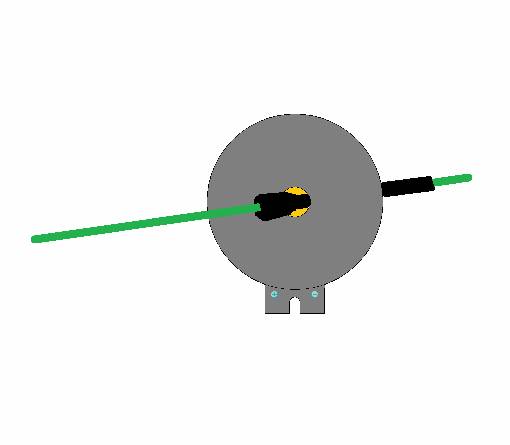

●Feature of ABH-8□ ABH-8□ is the smallest model by metal pipe use, as same size as the pencil. Since ABH-8□ uses metal pipe of φ8, it has mechanical rigidity. Pinpoint heating is possible with a φ 1 taper nozzle. The ...

Read More »《Ultra-small Air Blow Heater 》ABH-6□

●Feature of ABH-6□ The heating tube is a pencil size of φ 6. Because wind pressure is weak, it is suitable for cream soldering of printed circuit boards. The tip was ceramics of the insulation, so risk of electrical breakdown ...

Read More »《 Ultra-small Air Blow Heater 》ABH-4D

●Feature of ABH-4D The heating tube is ultra-small matchstick size of φ4, it is smaller than pencil. Since the base part is φ 6, it can be inserted and fixed in a metal pipe. The minimum length is L60, so ...

Read More »Dram can Level Sensor & Water surface oil film detector price list

Dram can Level Sensor Standard Type D/# Item and Description Price US$ DLC-100-2 Full Alarm Contact output US$1,275 DLC-100B2 Full Alarm Bell US$1,470 DLC-100L2 Full Alarm Lamp US$1,650 DLC-100BL2 Full Alarm Buzzer and Redlight US$1,845 DLC-800-2 Empty Alarm Contact output US$1,470 ...

Read More »Toughtape Price List

D/# Unit Price US$ TM-HT-25 1 unit 1 piece US$100 TM-HT-25 1 unit 10 piece US$900 Request for quotation

Read More »Far-Infrared Heater Price List

Far-infrared Point Heater FPH-30 D/# Cooling Voltage Wattage Mirror length Focus diameter Price US$ FPH-30/f15/6V-18W/P1m None AC/DC6V-18W 15mm Φ3 US$1,200 FPH-30/f30/6V-18W/P1m None AC/DC6V-18W 30mm Φ5 US$1,250 FPH-30A/f15/6V-18W/P1m Air AC/DC6V-18W 15mm Φ3 US$1,640 FPH-30A/f30/6V-18W/P1m Air AC/DC6V-18W 30mm Φ5 US$1,690 FPH-30/f15/6V-18W/WCU-30/P1m Water ...

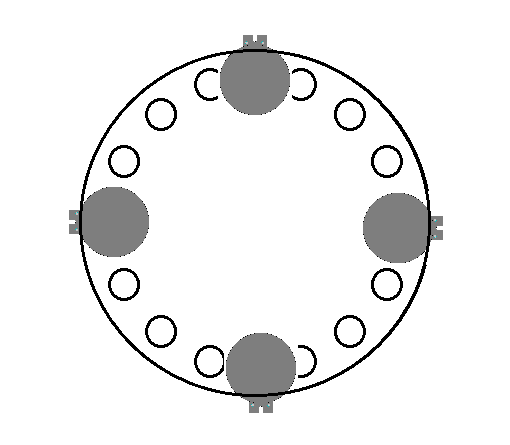

Read More »Halogen Ring Heater Price List

Halogen Ring Heater D/# Item and Description Price US$ HRH-C98/H10 Basic unit US$939 HRH-C98/H10/M Basic unit with mirror US$1,252 HRH-C98/H10/MG Basic unit with mirror and cover US$1,548 HRH-C98/H10/RH22 Basic unit with ring hood Φ22 US$1,635 HRH-C98/H10/RH40 Basic unit with ring ...

Read More »No.6 Heating on the Index Table

[ Problem Point ] There is no high speed heater of the corresponding to an index table, and We were in trouble. [ ⇒Kaizen Point ] Using a halogen ring heater with a reflector. Since the standup was speedy, the ...

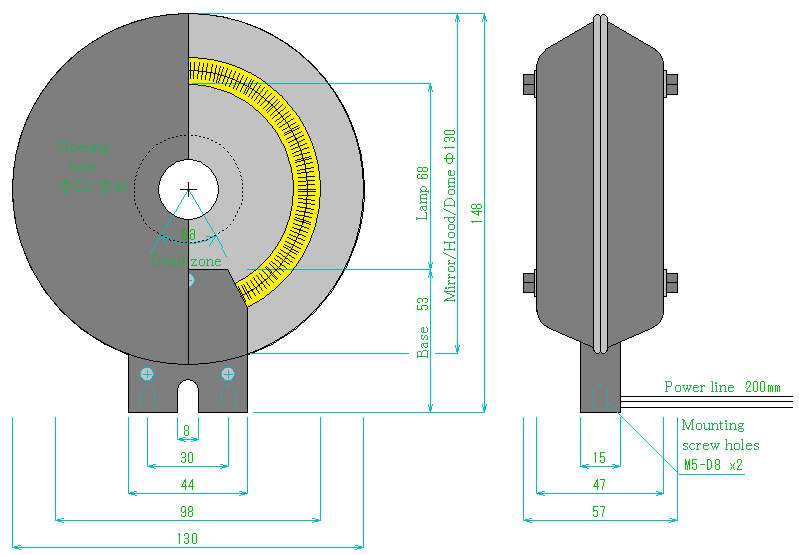

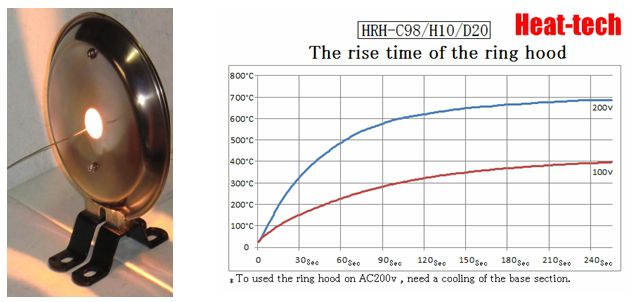

Read More »Halogen Ring Heater HRH-C98/H10/RH

Specifications Temperature characteristic Outline drawing Mounting bracket PDF Catalog Download

Read More »Halogen Ring Heater HRH-C98/H10/M(G)

Specifications Temperature characteristic Outline drawing Mounting bracket PDF Catalog Download

Read More »Halogen Ring Heater HRH-C98/H10

Specifications Temperature characteristic Outline drawing Mounting bracket PDF Catalog Download

Read More »No.5 Dryness of the silicon wafer

[ Problem Point ] There is no good way to small and wide heating and We were in trouble. [ ⇒Kaizen Point ] The ring heater which can carry out wide heating of the wide area was introduced. The efficiency ...

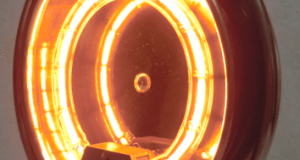

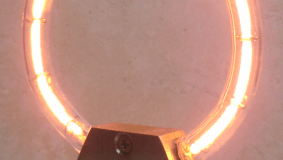

Read More »Instantaneous Heating Halogen Ring Heater HRH series

1. Simple heating, high temperature in the hood! High conversion efficiency from electrical to radiant energy, In the hood of the halogen lamp, high temperature reaches 650 ℃ will appear. 2. Instantaneous heating, the heating time can be shortened. ...

Read More »No.4 Dryness of capsule printing

[ Problem Point ] There is no good way to small and uniform heating and We were in trouble. [ ⇒Kaizen Point ] The ring heater which can carry out homogeneous heating of the wide area was introduced. The efficiency ...

Read More »No.3 Heating of the test piece

[ Problem Point ] There is no good method of observing the process of heating. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. Since the test piece inserted from ...

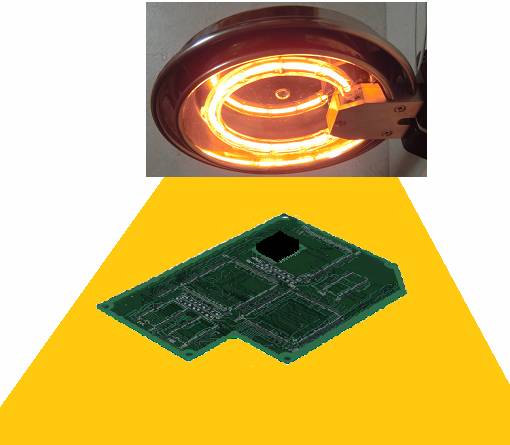

Read More »No.2 Preheating of the printed circuit board

[ Problem Point ] There is no good method of heat the small printed circuit board and We were in trouble. [ ⇒Kaizen Point ] The ring heater which can carry out uniform heating of the wide area was introduced. ...

Read More »No.1 Heat shrinking of wire harness

[ Problem Point ] There is no good method of heating from all direction. and We were in trouble. [ ⇒Kaizen Point ] Shrinking heating was carried out with the halogen ring heater. Since it heated from all the circumferences, ...

Read More »No.16 Residual quantity shortage warning of softener

[ Problem Point ] Softener disappear suddenly. [ ⇒Kaizen Point ] DLC-800A of the analog output type was installed. When the rest of a softener becomes little, a signal goes out. Non-attender operation could be done now. Production started also ...

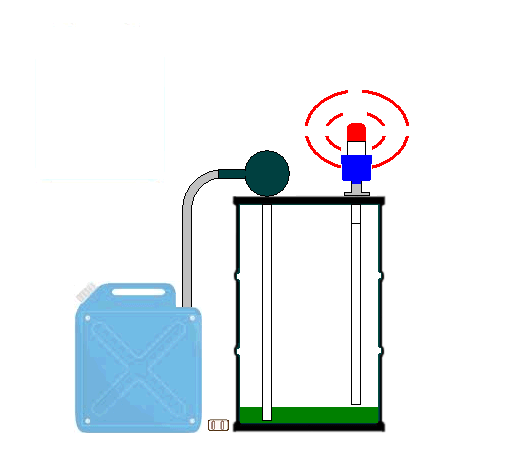

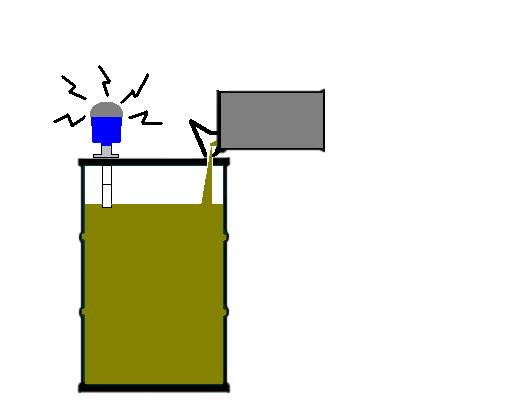

Read More »No.15 Residual quantity shortage warning of cooling oil

[ Problem Point ] Cooling oil disappear suddenly. [ ⇒Kaizen Point ] DLC-800L of the warning light type was installed. When the rest of cooling oil became little, the red light shone, so inventory control could be done now easily. ...

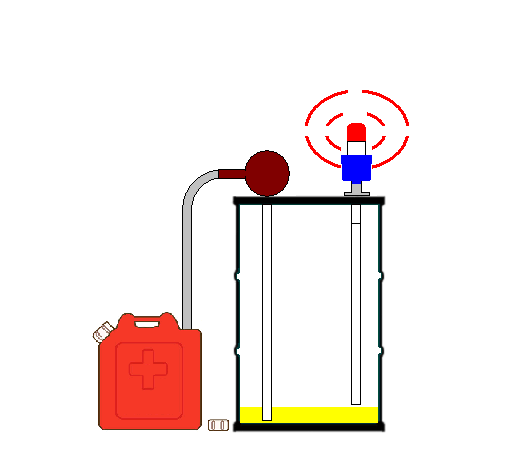

Read More »No.14 Residual quantity shortage warning of hydraulic fluid

[ Problem Point ] Hydraulic fluid disappear suddenly. [ ⇒Kaizen Point ] DLC-800L warning light type was installed. When the rest of hydraulic oil became little, the red light shone, so inventory control could be done now easily. Production started ...

Read More »No.13 Repacking of waste oil

[ Problem Point ] When it is full until overflowing, it doesn’t notice it. [ ⇒Kaizen Point ] Started using the DLC-100B Bell type. So loud 80 horn Bell Type. Even the work which doesn’t see the inside can be ...

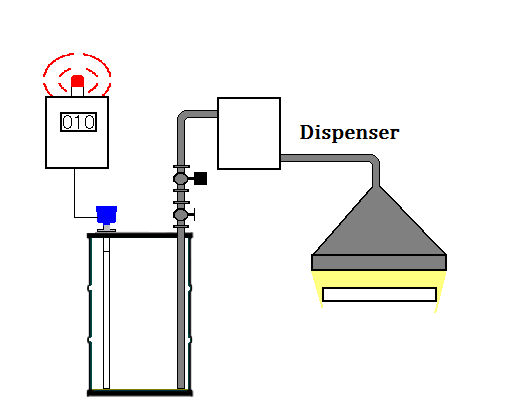

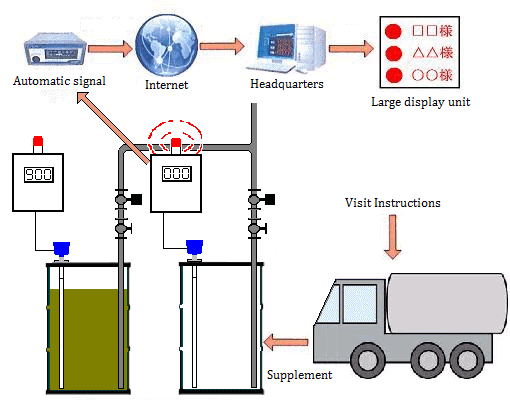

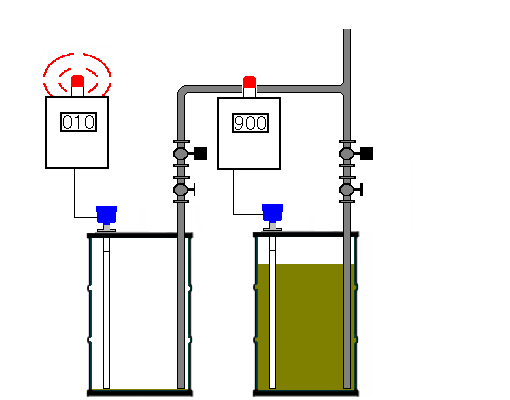

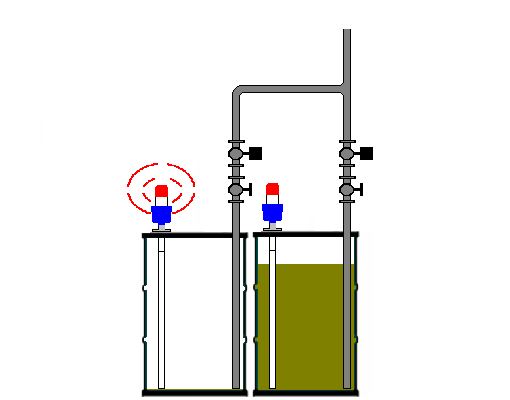

Read More »No.12 Fuel management and automatic replenishment of the liquid oil

[ Problem Point ] Liquid and oil disappear suddenly. [ ⇒Kaizen Point ] DLC-800A was installed. The signal comes out when the remainder of the liquid and oil decreases.The residual quantity shortage signal was sent to materials Management Division by ...

Read More »No.11 Inventory control of liquid and oil

[ Problem Point ] Liquid and oil disappear suddenly. [ ⇒Kaizen Point ] DLC-800A was installed. When the rest of liquid and oil became little, a signal went out, so inventory control could be done now easily. Production started also ...

Read More »No.10 Remaining quantity warning of liquid and oil

[ Problem Point ] Liquid and oil disappear suddenly. [ ⇒Kaizen Point ] DLC-800L of the warning light type was installed. When the rest of liquid and oil became little, the red light shone, so inventory control could be done ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop

![[ Small size Air Blow Heater ]ABH-10S](https://heater.heat-tech.biz/wp-content/uploads/2012/08/abh10s-enkotc1-300x160.jpg)

![[ Ultra-small Air Blow Heater ]ABH-8H](https://heater.heat-tech.biz/wp-content/uploads/2012/08/abh8h-en1-300x160.jpg)

![[ Ultra-small Air Blow Heater ]ABH-6M](https://heater.heat-tech.biz/wp-content/uploads/2012/08/abh6m-en1-300x160.jpg)