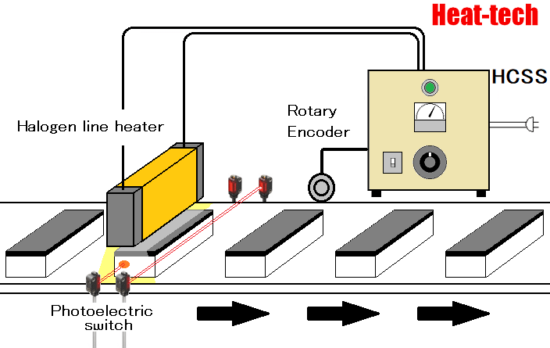

[ Problem Point ]

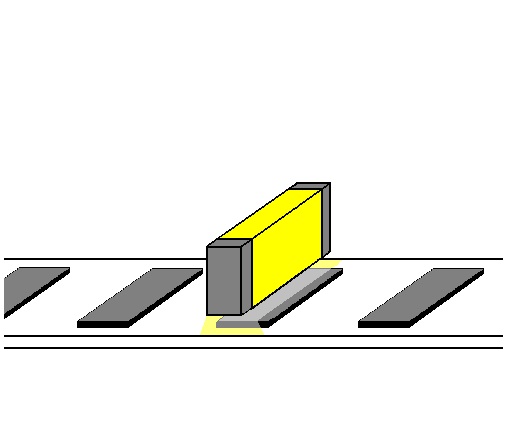

When the line stopped, the heated part became defective.

And when it was restarted, there were cases where unprocessed products were generated due to forgetting to turn on the switch.

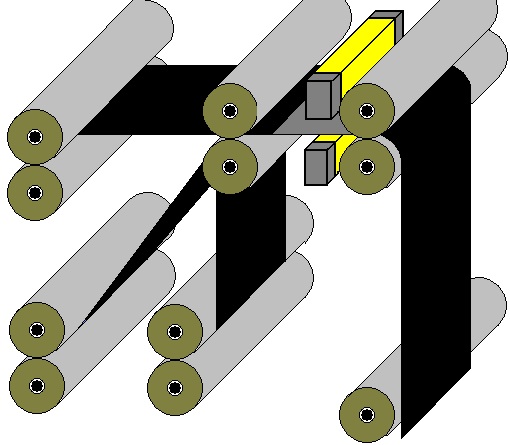

Also, even when there was no work, the heater was operating and power was wasted.

[ ⇒Kaizen Point ]

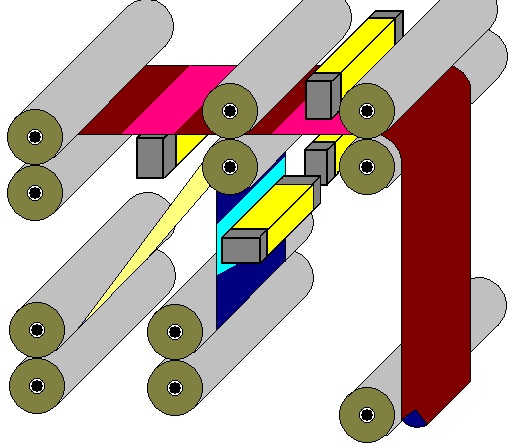

Using a speed proportional controller.

When the line is stopped, heating is automatically stopped, and when it is in operation, heating is restarted.

Automatically follows speed fluctuations, increasing yield.

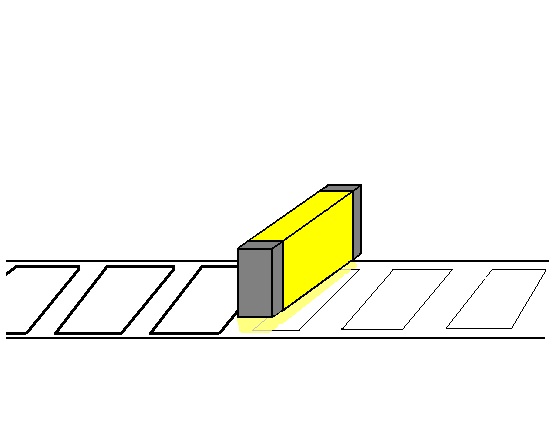

Since the work is detected by the photoelectric switch, the power is reduced when there is no work, which saves energy.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop