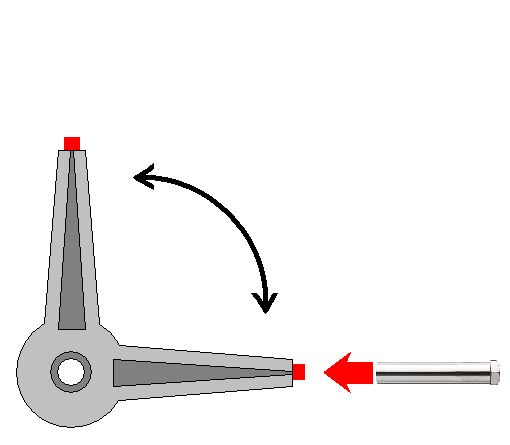

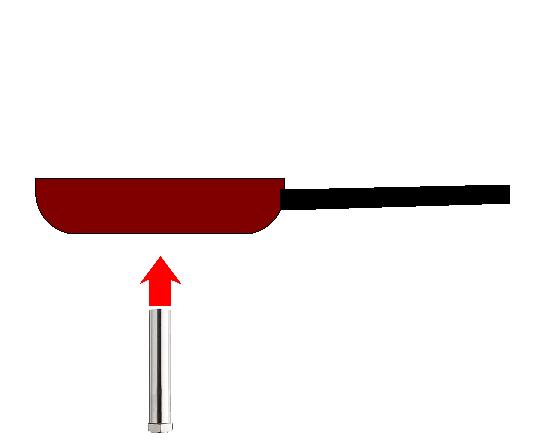

[ Problem Point ] There were no tools in which optimum temperature for heating the moving part, and We were in trouble. [ ⇒Kaizen Point ] Heated in the Air Blow Heater. Mobility could be maintained without contact can ...

Read More »No.60 Rapid heating process chamber

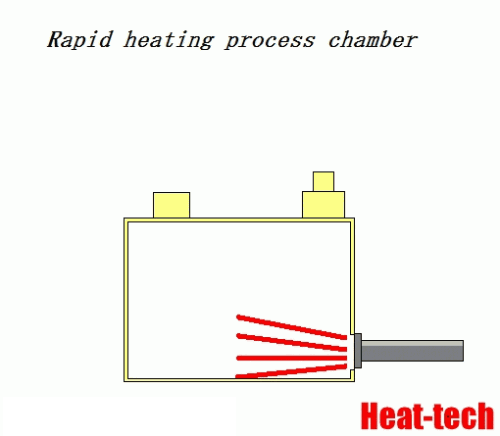

[ Problem Point ] The rapid heating is not possible to the chamber, had trouble. [ ⇒Kaizen Point ] In a large the Air Blow Heater warmed rapidly. The rise of the processing cycle time, significantly increasing the number of ...

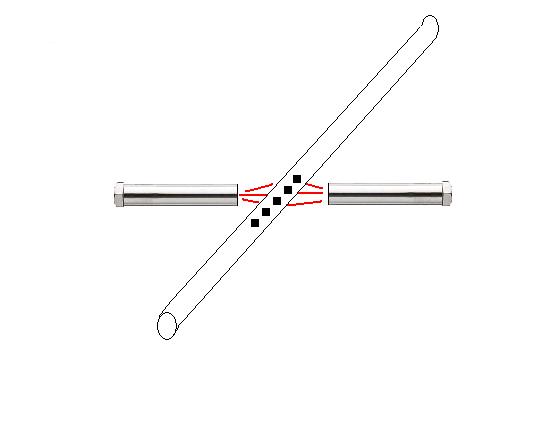

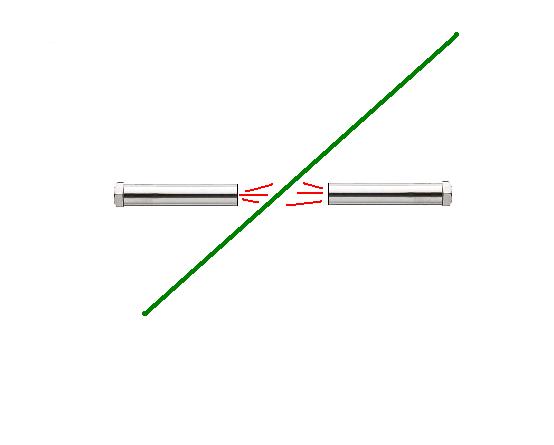

Read More »No.55 Internal drying of pipe products

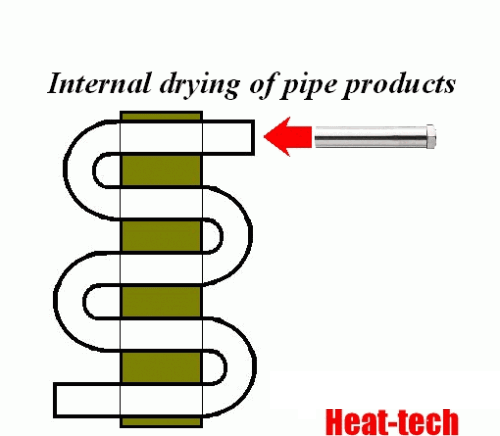

[ Problem Point ] It was in trouble because Flushing cleaning solution after plumbing processing was left. [ ⇒Kaizen Point ] Rust did not go out because it had dried remaining water by the Air Blow Heater.

Read More »No.54 Drying of Drilled Hole

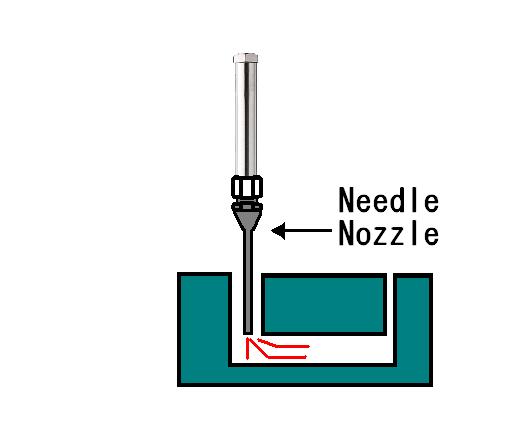

[ Problem Point ] When cleaning after cutting chips, water drops were still in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,attached to the needle nozzle,dry blower. Because the hot air blower hot moment, better drying.

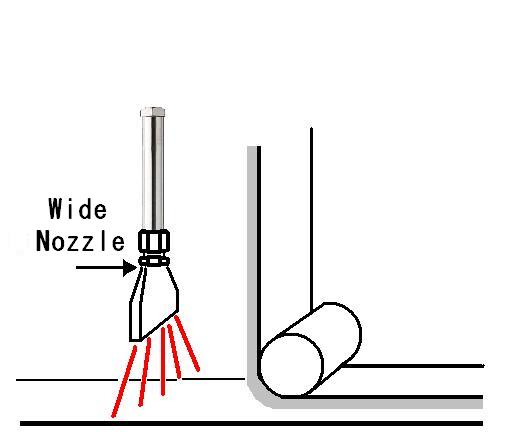

Read More »No.53 Bonding of the film and paper

[ Problem Point ] When the adhesive film and paper,air bubbles were made trouble. [ ⇒Kaizen Point ] Wide nozzle attached to the preheated the Air Blow Heater. To improve the adhesion of air bubbles disappeared.

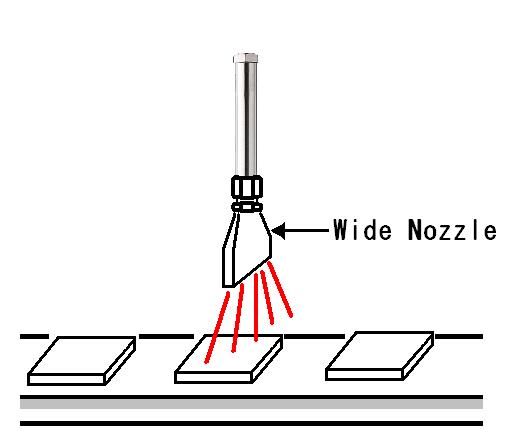

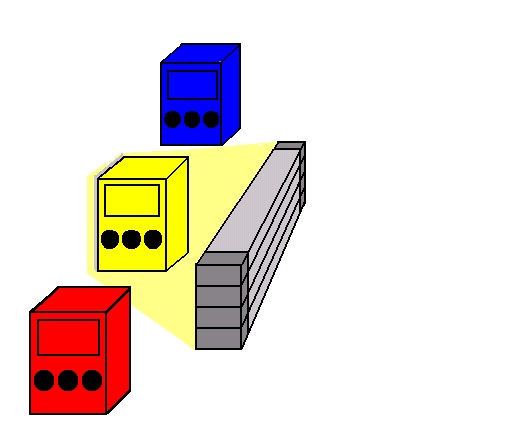

Read More »No.52 Aging of electronic components

[ Problem Point ] It’s being checked by the tester just after the production of electronic components. Control of the heat cycle was difficult. [ ⇒Kaizen Point ] Aging was done with a wide nozzle of the Air Blow Heater. ...

Read More »No.50 Dryness of the electric wire mark print

[ Problem Point ] Resin insulating coating was being used,so control of the dry temperature was difficult. [ ⇒Kaizen Point ] It dried spotting heating by the Air Blow Heater. The quality of the product has improved in the accurate ...

Read More »No.49 Dryness of electric wire

[ Problem Point ] Resin insulating coating was being used,so control of the dry temperature was difficult. [ ⇒Kaizen Point ] It dried spotting heating by the Air Blow Heater. The quality of the product has improved in the accurate ...

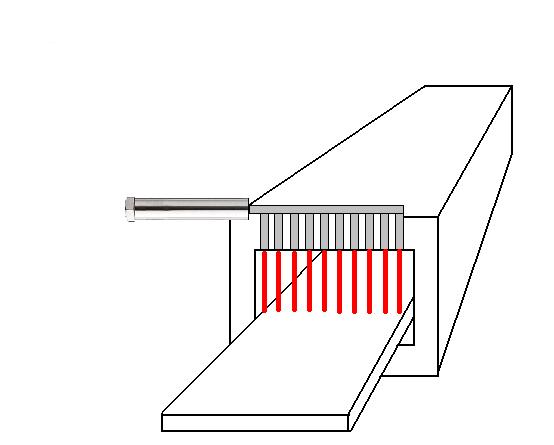

Read More »No.48 Air curtain of furnace

[ Problem Point ] Heat ran away from the furnace,was the problem of quenching quality. [ ⇒Kaizen Point ] The furnace was air sealed with the Air Blow Heater. The temperature of the interior was kept,and the quality of quenching ...

Read More »No.47 Replacement of gas in laboratory electrified

[ Problem Point ] Laboratory has been electrified,the gas was not able to be used and I was in trouble. [ ⇒Kaizen Point ] It was heated by the Air Blow Heater. It was very useful for high temperature heating ...

Read More »No.42 Dryness and stiffening of wire covering

[ Problem Point ] We have no idea about high temperature heater on short time. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could ...

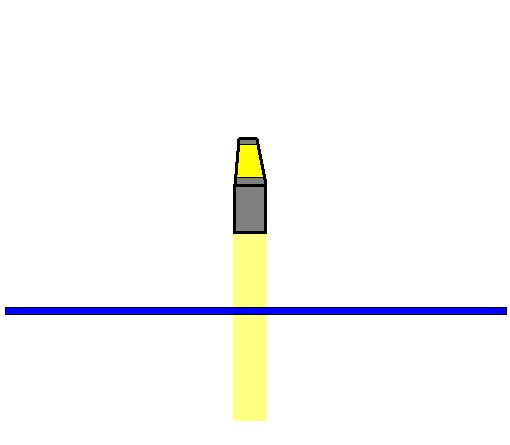

Read More »No.41 Semiconductor wafer heat-treatment process

[ Problem Point ] We have no idea how to heat semiconductor wafer in the vacuum chamber. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of ...

Read More »No.40 Deposition of aluminum

[ Problem Point ] We have no idea how to deposition of aluminum in the vacuum chamber. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of ...

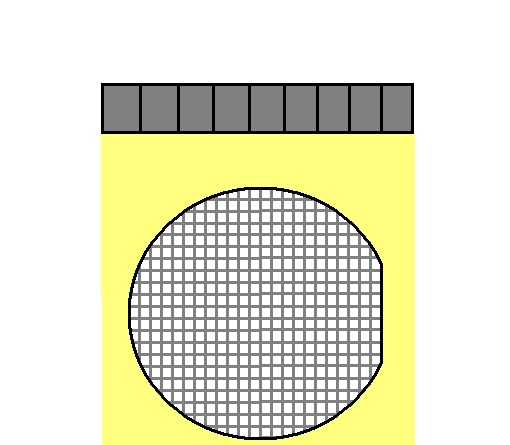

Read More »No.42 Drying of silicon wafers

[ Problem Point ] The conventional method was in trouble because it contains metal ions in dry air. [ ⇒Kaizen Point ] Heated and dried in the Air Blow Heater designed for clean room. Since heating the coated glass,and metal ...

Read More »No.40 Heat shrinking of lithium batteries

[ Problem Point ] We used the industry dryer. Unable to fine temperature control was a problem. [ ⇒Kaizen Point ] Heated only the surface by the small calorie by the Air Blow Heater and made them shrink. Does not ...

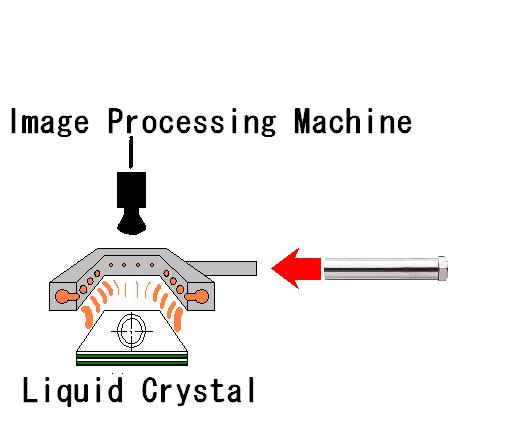

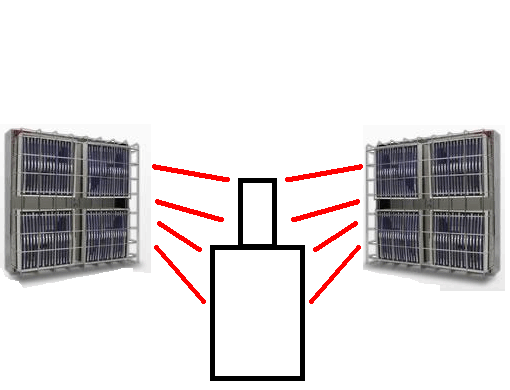

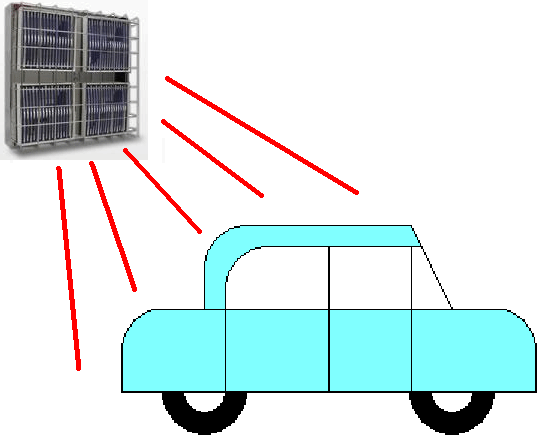

Read More »No.37 Thermal distortion check of liquid crystal

[ Problem Point ] There was no suitable one to check the thermal distortion of liquid crystal. [ ⇒Kaizen Point ] It was necessary to do 100% inspection and an image processing machine was adopted, so the central part was ...

Read More »No.11 Anneal of glass

[ Problem Point ] We have no idea about good annealing of the glass. [ ⇒Kaizen Point ] Warming by the Ir Panel Heater. Glass is able to be warmed on the broad wavelength.

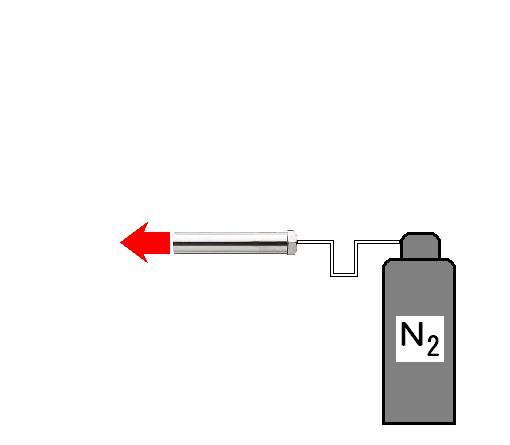

Read More »No.27 Production of hot nitrogen gas

[ Problem Point ] It wasn’t possible to make hot nitrogen gas while keeping the purity. [ ⇒Kaizen Point ] Nitrogen was heated by the Air Blow Heater. Air didn’t get mixed and it was possible to make high temperature ...

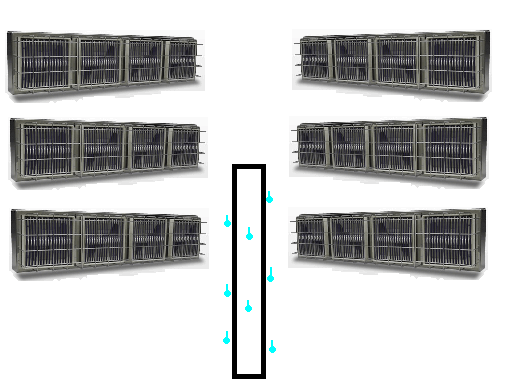

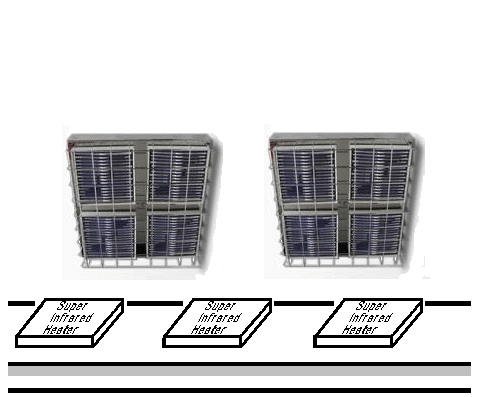

Read More »No.8 Heating unit for drying booth

[ Problem Point ] We have no idea about heating unit for drying booth. [ ⇒Kaizen Point ] Drying by the Ir Panel Heater. Since rapid heat up on drying booth,increased uptime. Now able to respond flexibly to unexpected interrupt ...

Read More »No.7 Curing of the epoxy resin

[ Problem Point ] We have no idea about curing of the epoxy resin. [ ⇒Kaizen Point ] Curing by the Ir Panel Heater. Since rapid curing, increased uptime. Now able to respond flexibly to unexpected interrupt work.

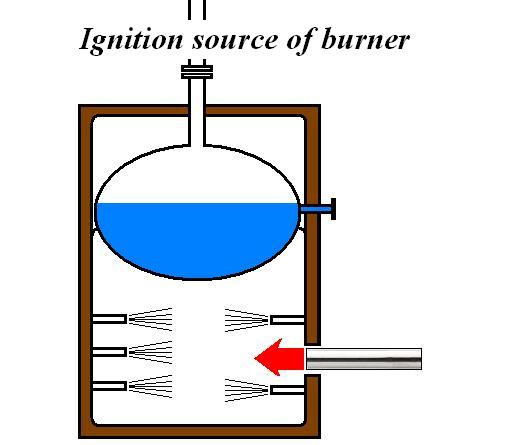

Read More »No.23 Ignition source of burner

[ Problem Point ] We were in trouble because there were no small ignition sources. [ ⇒Kaizen Point ] The Air Blow Heater ignited heated to high temperature.

Read More »No.18 Touch-up in consumer electronic repairer place

[ Problem Point ] We have no idea about small and strong quickly heater. [ ⇒Kaizen Point ] The touch-up was dried with the Halogen Line Heater. It was possible to work while preventing the heat damage of other parts ...

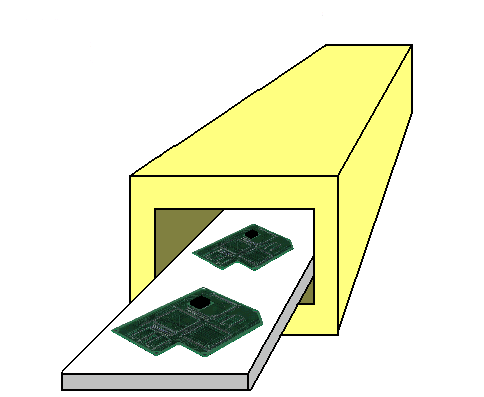

Read More »No.4 Reflow of printed circuit boards

[ Problem Point ] We have no idea about Reflow of printed circuit boards. [ ⇒Kaizen Point ] Reflow by the Ir Panel Heater. Since rapid heating, increased uptime. Now able to respond flexibly to unexpected interrupt work.

Read More »No.3 Dryness of a silk print

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Dried by the Ir Panel Heater. Since the dryer is heated quickly, no longer waiting time. Now able to respond flexibly to unexpected interrupt ...

Read More »No.2 Touch-up dryer

[ Problem Point ] Starting of a drier took time too much. [ ⇒Kaizen Point ] Dried by the Ir Panel Heater. Since the dryer is heated quickly, no longer waiting time. Now able to respond flexibly to unexpected interrupt ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop