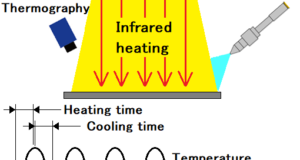

[ Problem Point ] We were looking for a heater that would synchronize with the pulse signal. [ ⇒Kaizen Point ] By changing the applied frequency, it was possible to limit the area of the heat generation point. When applied ...

Read More »No.22 Improved quality when cutting resin holes

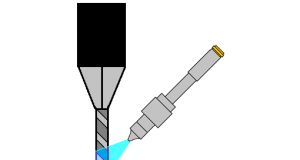

《Problem Point 》 The resin was fused to the drill due to frictional heat, which was a problem. 《⇒Kaizen Point 》 An Air Blow Cooler was used. The MTBF was improved because the resin did not adhere.

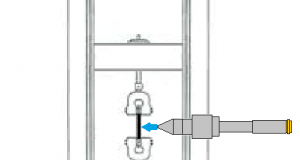

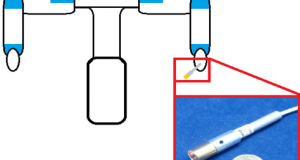

Read More »No.13 Tensile tester low temperature setting

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

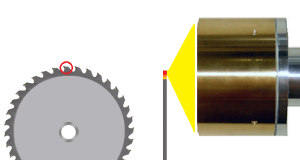

Read More »No.40 Soldering of tip saw

[ Problem Point ] There was no easy way to set the tip of the tip saw to 1000℃ [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Since it can be processed ...

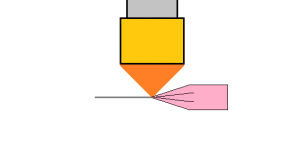

Read More »No.1 Pinpoint heating of resin

[ Problem Point ] There was no compact heater of far infrared which can pinpoint point the resin. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-30. The welding of the resin got to work gently.

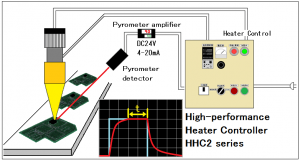

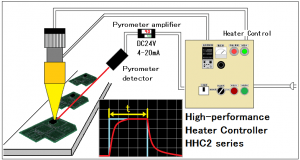

Read More »No.6 Control of a dry time for solvent system adhesive

[ Problem Point ] It took a certain amount of curing at a stable temperature without overshoot. [ ⇒Kaizen Point ] Using the heat retention time control function of highly functional heater controller HHC2. The heating time was tested in ...

Read More »No.5 Heating time control for condition setting

[ Problem Point ] It was necessary to set conditions as to whether heating could be done within the takt time. [ ⇒Kaizen Point ] Using the heat time control function of highly functional heater controller HHC2. The heating time ...

Read More »No.37 Heating processing of the double-arm robot

[ Problem Point ] There was no compact heater that can be mounted on a dual arm robot. [ ⇒Kaizen Point ] It was heated using microminiature Halogen Point Heater HPH-12. Handling became easy since it is a finger size ...

Read More »No.51 Heating and drying of the sealer

[ Problem Point ] It is necessary to shorten the drying time of the sealer. [ ⇒Kaizen Point ] We were using the line condensing type halogen line heater. Because the line condensing type, in accordance with the application position ...

Read More »No.50 Drying after car wash

[ Problem Point ] It is necessary to reduce the draining drying time. [ ⇒Kaizen Point ] We were using the parallel light type halogen line heater. Because the light heating, non-contact heating is possible, it was able to shorten ...

Read More »No.34 Borosilicate glass tube melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass tube was melted using a halogen point heater. The glass tube processing process was composed only by electric equipment. In addition, ...

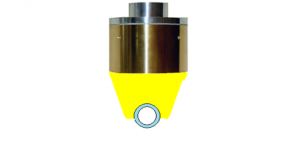

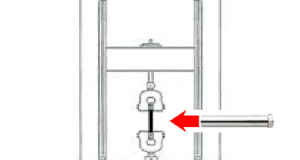

Read More »No.105 Shrink fitting of a small cylinder

[ Problem Point ] Heating equipment that can be used in online was necessary. [ ⇒Kaizen Point ] We ware shrink-fitted by using the Air Blow Heater. The start of the line become faster. Installation because it does not use ...

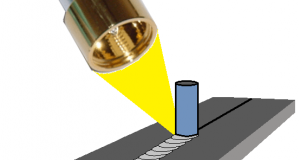

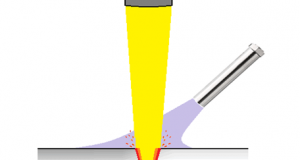

Read More »No.32 Auxiliary heat source of friction stir welding

[ Problem Point ] There was not a heating method to make a steel sheet a high temperature in pinpoint. [ ⇒Kaizen Point ] We have auxiliary heating using a halogen point heater. Because it is heated to a high ...

Read More »No.29 The distortion test by partial heating of precision parts

[ Problem Point ] It could not distorted test due to sliding heating of precision parts. [ ⇒Kaizen Point ] The precision parts by using a halogen point heater was high temperature heating. Since can be heated to a high ...

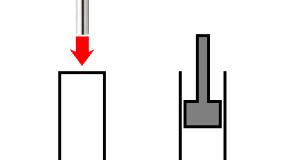

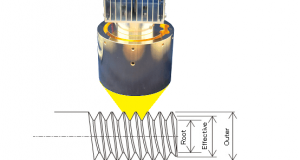

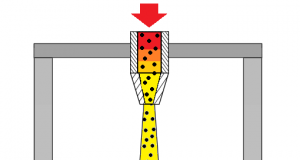

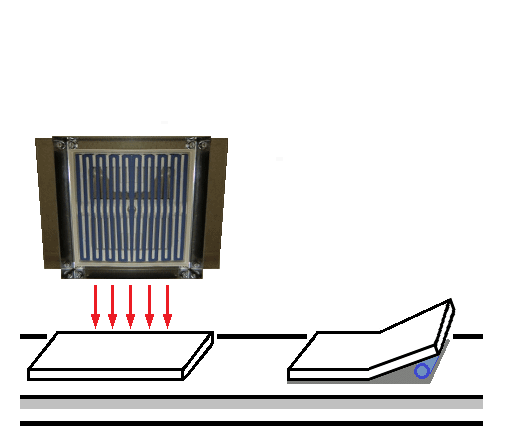

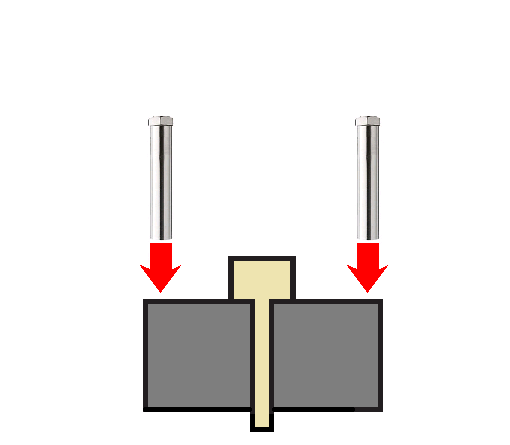

Read More »No.28 Infrared heat caulking of resin boss

[ Problem Point ] Resin adheres to the punch, and this has been a cause of the processing failure. [ ⇒Kaizen Point ] We use tha halogen point heater heating the resin boss. Problem is solved because construction methods that ...

Read More »No.23 Temperature setting of the tensile testing machine (non-magnetic material and high temperature)

[ Problem Point ] The equipment which can heat a nonmagnetic material to high temperature was required. [ ⇒Kaizen Point ] The use of a Halogen Point Heater that can be high-temperature heating in a short time. Heating process energy ...

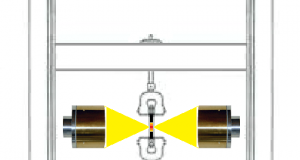

Read More »No.96 Heating of the shielding gas of laser welding

[ Problem Point ] Oxide film on the weld surface is worried about. [ ⇒Kaizen Point ] High temperature heating of the shielding gas was carried out using the hot wind heater. Even if it thickened metal, welding said well.

Read More »No.95 Hot air shot peening

[ Problem Point ] In order to thicken a metallic thin film, the high temperature hot wind was required. [ ⇒Kaizen Point ] The shot-peened under high temperature conditions using the Air Blow Heater. Junction went well even if thickening ...

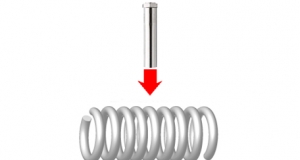

Read More »No.92 Temperature setting of the coil spring testing machine (low-temperature material)

[ Problem Point ] There was no evaluate the performance while changing the temperature of the coil springs. [ ⇒Kaizen Point ] It heated from room temperature to 850℃ with the Air blow heater. The quality assessment in the arbitrary ...

Read More »No.91 Temperature setting of the tensile testing machine (low-temperature material)

[ Problem Point ] There was no evaluate the performance while changing the temperature of the test piece. [ ⇒Kaizen Point ] It heated from room temperature to 850℃ with the Air blow heater. The quality assessment in the arbitrary ...

Read More »No.90 Heat test of bearing

[ Problem Point ] Managing the heat-resistant temperature of grease, it came to carry out a quality assessment and there was nothing. [ ⇒Kaizen Point ] It heated from room temperature to 550℃ with the Air blow heater. The quality ...

Read More »No.18 Point heating and drying of the sealant

[ Problem Point ] In the winter, it is in trouble sealant without drying out. [ ⇒Kaizen Point ] Dry by heating with a Halogen Point Heater. Easy dried.

Read More »No.15 Heating of the LCD cover glass

[ Problem Point ] Rubber was not drying, and it was troubled by the temperature close to the sub-zero winter. [ ⇒Kaizen Point ] It was heated by the far-infrared heater which temperature rise of the high speed. Rise time ...

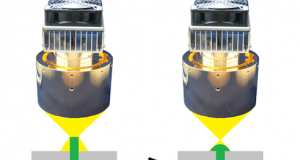

Read More »No.88 Thermal caulking of resin parts

[ Problem Point ] There was no non-contact heater that can be accurately temperature control. [ ⇒Kaizen Point ] We were heated in the Air Blow Heater. In the hot air that was temperature-controlled exactly, we were able to be ...

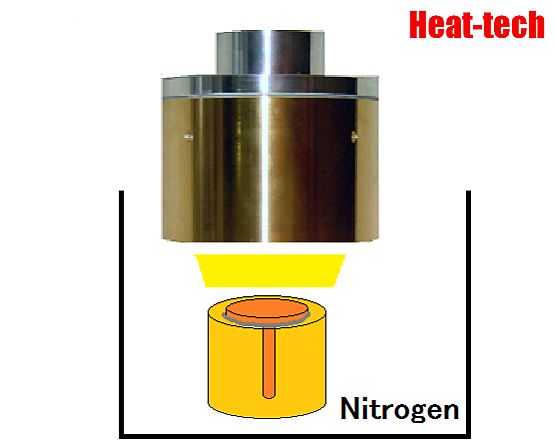

Read More »No.17 Brazing of Mini Valve

[ Problem Point ] We have no idea about good way to brazing in the no-oxygen. [ ⇒Kaizen Point ] It was brazed with a small Halogen Point Heater. Junction quality is improved.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop