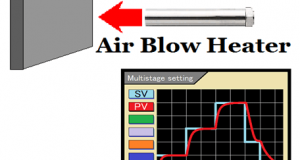

[ Problem Point ] The advanced battery with environment resistance is required for. [ ⇒Kaizen Point ] The temperature test was done using the Air Blow Heater.The rapid temperature change which was impossible until now has been reproduced.The dynamic characteristic ...

Read More »No.90 Heat test of bearing

[ Problem Point ] Managing the heat-resistant temperature of grease, it came to carry out a quality assessment and there was nothing. [ ⇒Kaizen Point ] It heated from room temperature to 550℃ with the Air blow heater. The quality ...

Read More »No.21 Heat source of CVD Reactor Using Concerntrated Infrared Heater

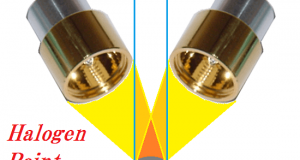

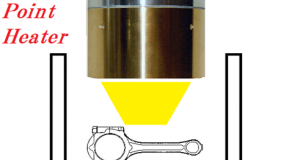

[ Problem Point ] The heating furnace with controllability, that is highly compact and high energy efficiency was required. [ ⇒Kaizen Point ] The use of a Halogen Point Heater that can be high-temperature heating in a short time. Heating ...

Read More »No.19 Performance testing of heat-resisting metal

[ Problem Point ] It is in trouble if there is no heater in a high temperature in a short period of time. [ ⇒Kaizen Point ] Heat-resisting metal is heated at a high output Halogen Point Heater of 3kw. ...

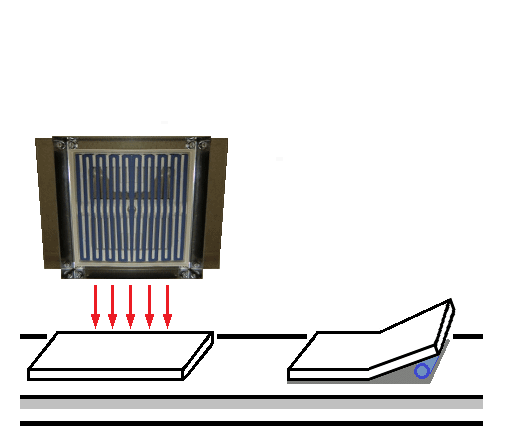

Read More »No.15 Heating of the LCD cover glass

[ Problem Point ] Rubber was not drying, and it was troubled by the temperature close to the sub-zero winter. [ ⇒Kaizen Point ] It was heated by the far-infrared heater which temperature rise of the high speed. Rise time ...

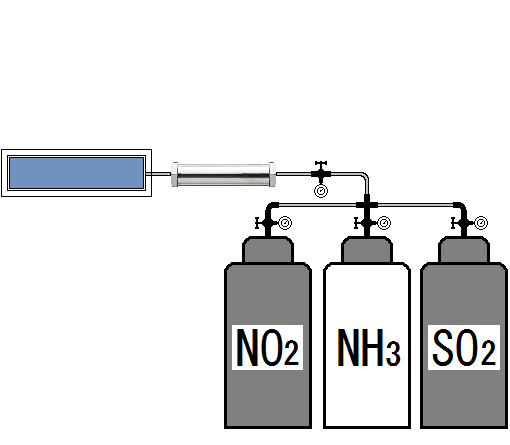

Read More »No.89 Heating of the gas for evaluation

[ Problem Point ] Could not be heated the dummy gas to evaluate the performance of the catalyst. [ ⇒Kaizen Point ] The double glazing tube specification DGH type for medicine-proof of the Air Blow Heater was used, and it ...

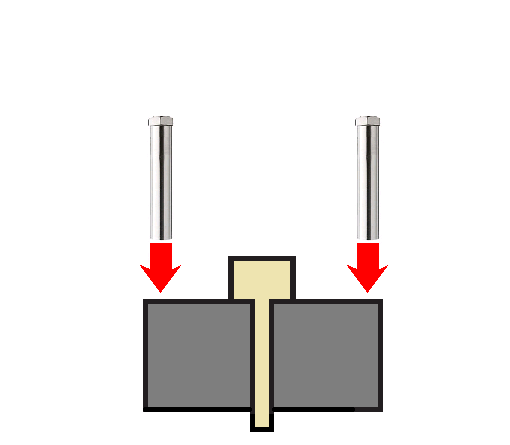

Read More »No.88 Thermal caulking of resin parts

[ Problem Point ] There was no non-contact heater that can be accurately temperature control. [ ⇒Kaizen Point ] We were heated in the Air Blow Heater. In the hot air that was temperature-controlled exactly, we were able to be ...

Read More »No.17 Brazing of Mini Valve

[ Problem Point ] We have no idea about good way to brazing in the no-oxygen. [ ⇒Kaizen Point ] It was brazed with a small Halogen Point Heater. Junction quality is improved.

Read More »No.16 Brazing of fuel cell vehicles pipe

[ Problem Point ] We have no idea about good way to brazing in the no-oxygen. [ ⇒Kaizen Point ] It was brazed with a small Halogen Point Heater. Junction quality is improved.

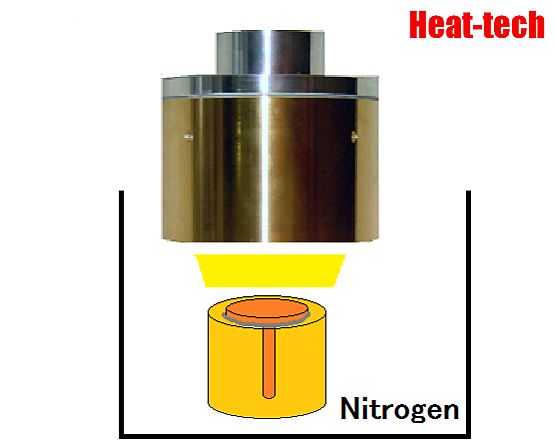

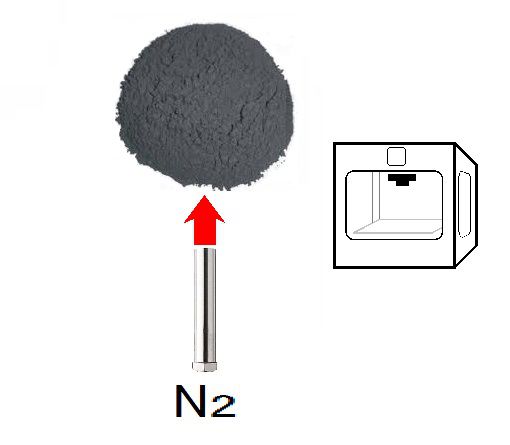

Read More »No.85 Breeze nitrogen heating of powder metal for 3D printer

[ Problem Point ] There was no the Air Blow Heater that can be heated in a nitrogen breeze. [ ⇒Kaizen Point ] We were heated in the breeze by the Air Blow Heater ABH100v-50w/10PS. It is possible to heat ...

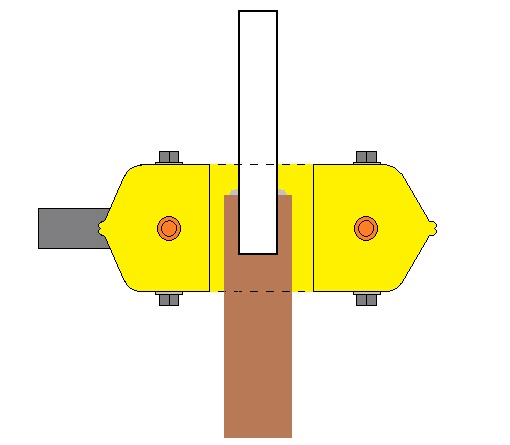

Read More »No.9 Silver low attachment of a cylinder work

[ Problem Point ] There is no good method of carrying out circular high temperature heating. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was smoothly heated in ...

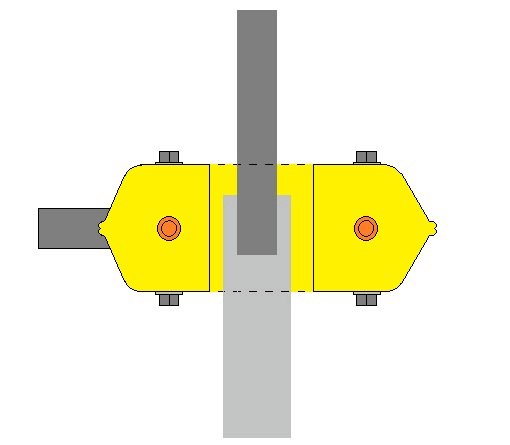

Read More »No.8 Caulking and heat shrinkage fit of a cylinder work

[ Problem Point ] There is no better way to heat evenly from the periphery. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was fitted to the expansion ...

Read More »No.7 Welding rod resin

[ Problem Point ] There is no better way to heat evenly from the periphery. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. From the feed port, it is ...

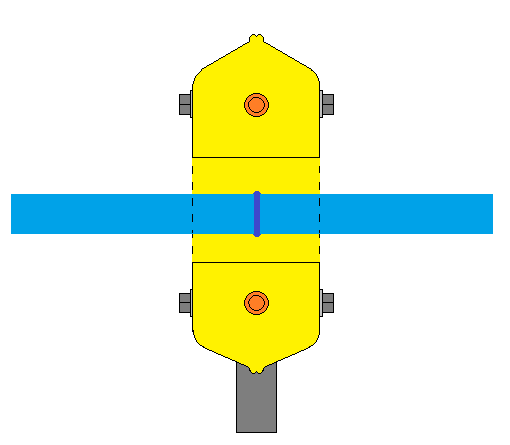

Read More »No.6 Heating on the Index Table

[ Problem Point ] There is no high speed heater of the corresponding to an index table, and We were in trouble. [ ⇒Kaizen Point ] Using a halogen ring heater with a reflector. Since the standup was speedy, the ...

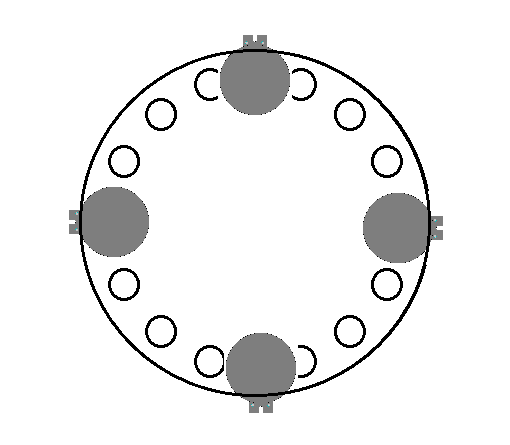

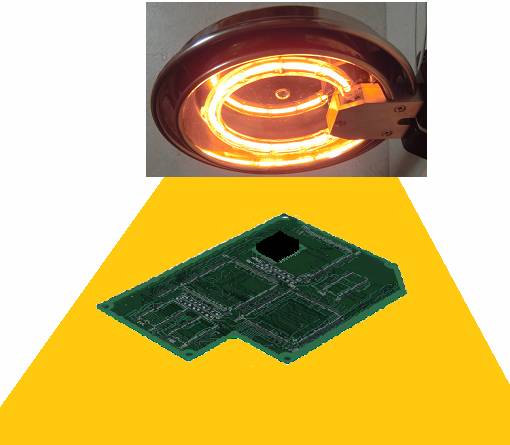

Read More »No.2 Preheating of the printed circuit board

[ Problem Point ] There is no good method of heat the small printed circuit board and We were in trouble. [ ⇒Kaizen Point ] The ring heater which can carry out uniform heating of the wide area was introduced. ...

Read More »No.1 Heat shrinking of wire harness

[ Problem Point ] There is no good method of heating from all direction. and We were in trouble. [ ⇒Kaizen Point ] Shrinking heating was carried out with the halogen ring heater. Since it heated from all the circumferences, ...

Read More »No.84 Study of shape memory alloy

[ Problem Point ] Temperature control was difficult because it was heating with warm water. [ ⇒Kaizen Point ] The alloy heated by the Air Blow Heater. since it heated at an exact temperature of a unit once, reproducibility of ...

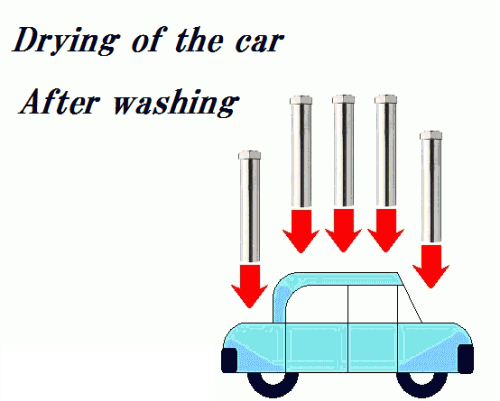

Read More »No.82 Drying of the car after washing

[ Problem Point ] When winter came, it was troubled without the waterdrop after car washing getting dry. [ ⇒Kaizen Point ] Drained and dried with the Air Blow Heater.

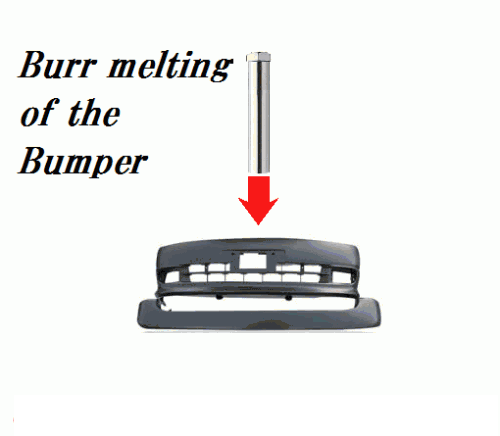

Read More »No.81 Burr melting of the Bumper

[ Problem Point ] Although the drier for industry was used for the robot, having attached it, broke down immediately and we were troubled. [ ⇒Kaizen Point ] The burr was melted with the Air Blow Heater. Since discharge temperature ...

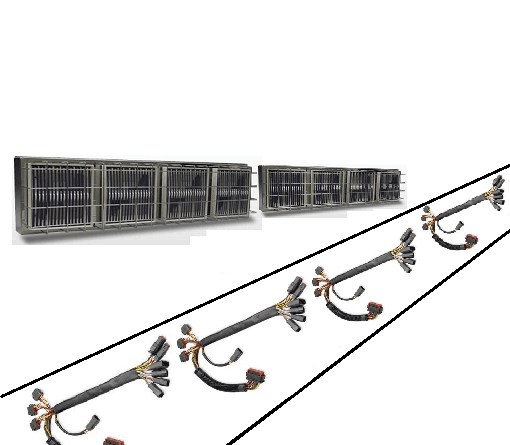

Read More »No.13 Heating and keeping warm of wire harness

[ Problem Point ] The wire did not fit, it was troubled by the temperature near the freezing point of winter. [ ⇒Kaizen Point ] It warmed by the Super Infrared Heater of temperature up at the moment. The wire ...

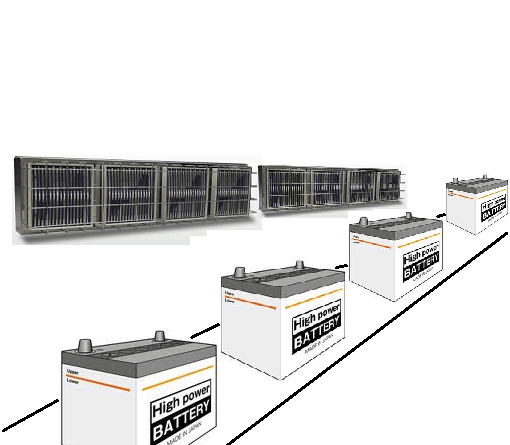

Read More »No.12 Heating and keeping warm of car battery

[ Problem Point ] The performance of the battery did not come out but it was troubled by the temperature near the freezing point of winter. [ ⇒Kaizen Point ] It warmed by the Super Infrared Heater of temperature up ...

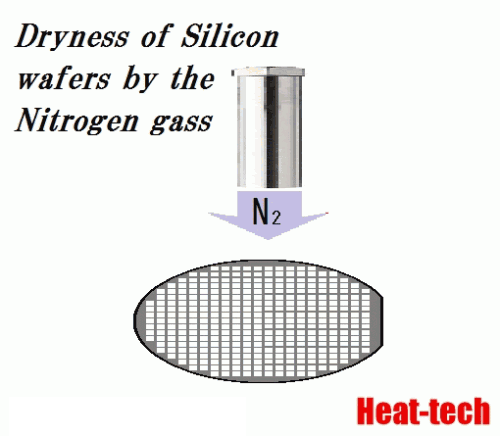

Read More »No.78 Dryness of Silicon wafers by the Nitrogen gas

[ Problem Point ] The marks of water drop remained and were worrisome when natural drying was carried out. [ ⇒Kaizen Point ] Nitrogen was heated with the Air Blow Heater and it dried. The marks of water drop were ...

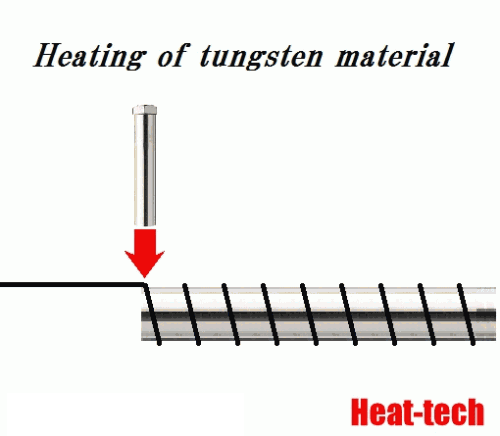

Read More »No.77 Heating of tungsten material

[ Problem Point ] When processing the wire produced by powder metallurgy,it had trouble to cracking or cutting. [ ⇒Kaizen Point ] So brittle,while heating to the processing 400 ℃ – 700 ℃ by the Air Blow Heater. The quality ...

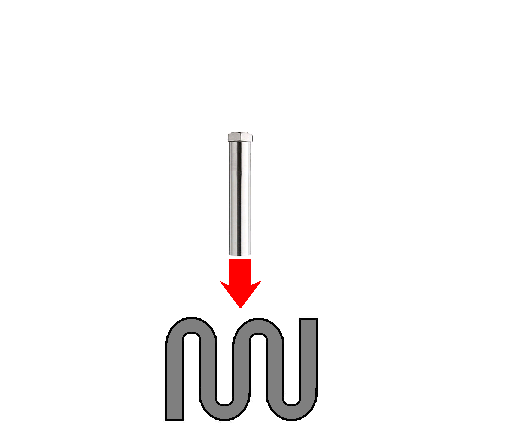

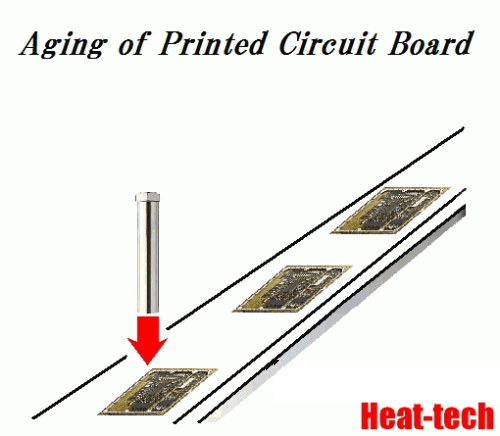

Read More »No.75 Aging of Printed Circuit Board

[ Problem Point ] We have no idea about how to no-contact heating in line. [ ⇒Kaizen Point ] The high temperature air of the suitable temperature was made with the Air Blow Hater and it projected. It came to ...

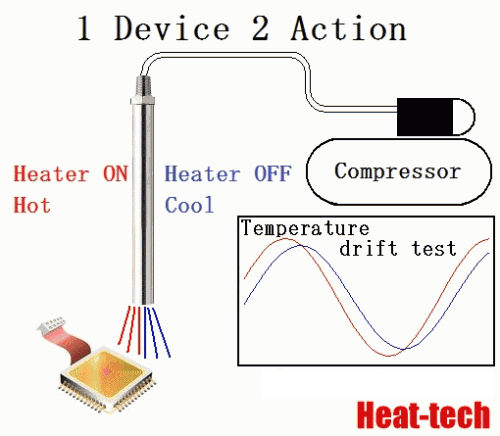

Read More »No.74 Temperature drift test of electronic device

[ Problem Point ] We have no idea about how to heating and cooling at the same time in line. [ ⇒Kaizen Point ] It made high fever air of a suitable temperature with the Air Blow Heater, projected and ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop