[ Problem Point ] It is very difficult to annealing temperature control. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater casting surface. Since the maximum temperature heated up in 5sec, immediately after the start of operation could work.The ...

Read More »No.40 Heat shrinking of lithium batteries

[ Problem Point ] We used the industry dryer. Unable to fine temperature control was a problem. [ ⇒Kaizen Point ] Heated only the surface by the small calorie by the Air Blow Heater and made them shrink. Does not ...

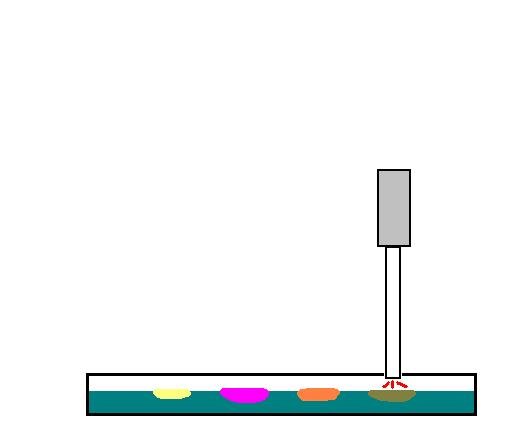

Read More »No.36 Heating in the vacuum chamber

[ Problem Point ] We have no idea about how to heat in the vacuum chamber. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation ...

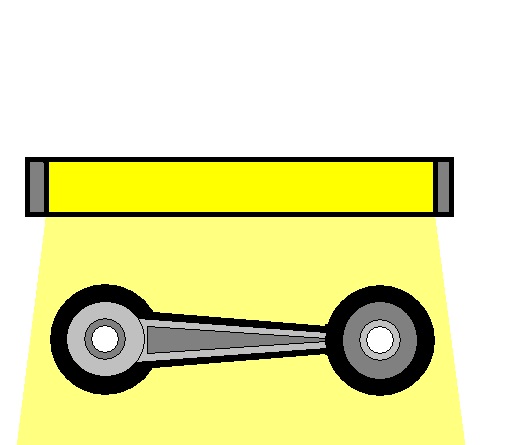

Read More »No.39 Peel seal and Sticker remover

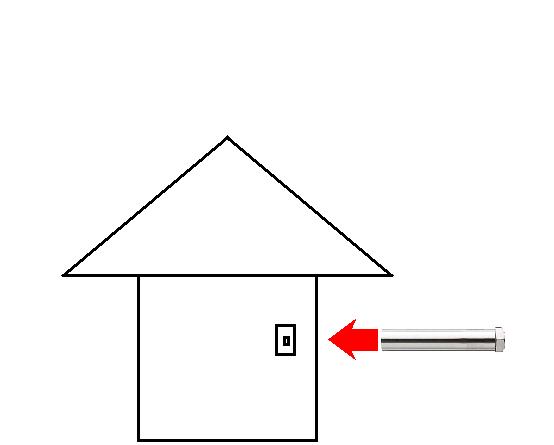

[ Problem Point ] Had trouble peeling off the seal is broken at the end. [ ⇒Kaizen Point ] A spot was heated by the Air Blow Heater and the glue was made soft. The productivity came off well,and improved.

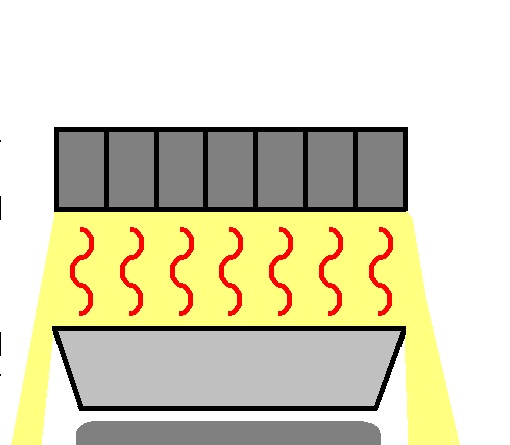

Read More »No.35 Keeping warm of food

[ Problem Point ] Rising of the heater is slow, the heat activity is bad. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could ...

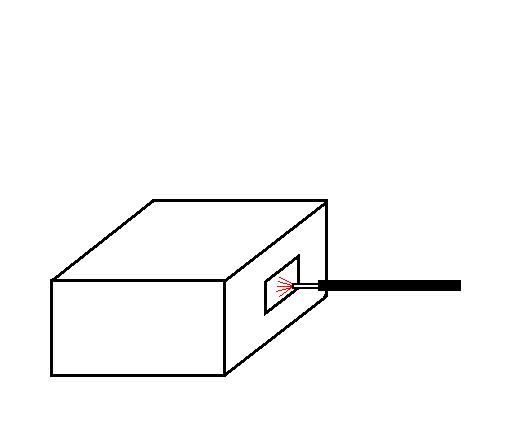

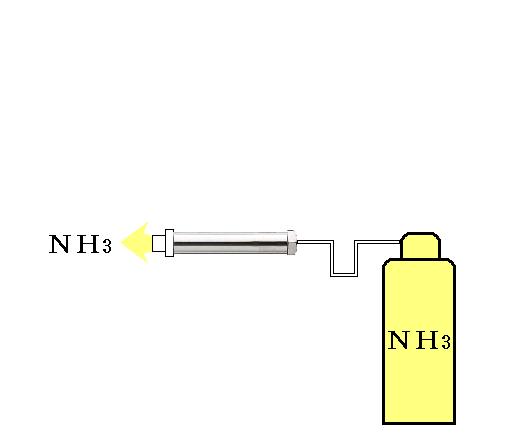

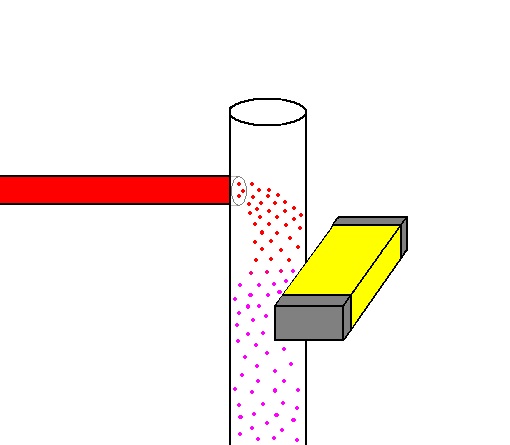

Read More »No.38 Ammonia gas heating

[ Problem Point ] The ammonia gas was dangerous,so it couldn’t be heated safely and I was in trouble. [ ⇒Kaizen Point ] It was heated airtightly by a DGH series of the Air Blow Heater. An experiment heated it ...

Read More »No.34 Dryness of food

[ Problem Point ] Rising of the heater is slow, the productivity is bad. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could work.The ...

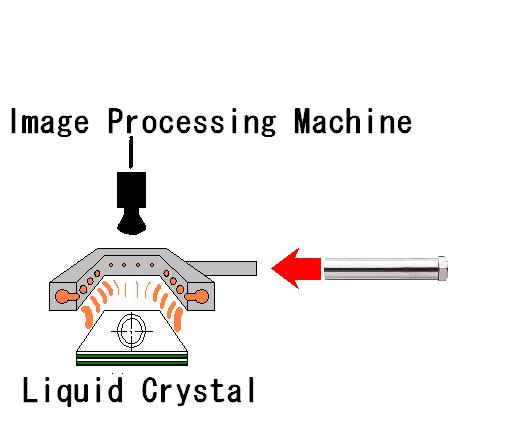

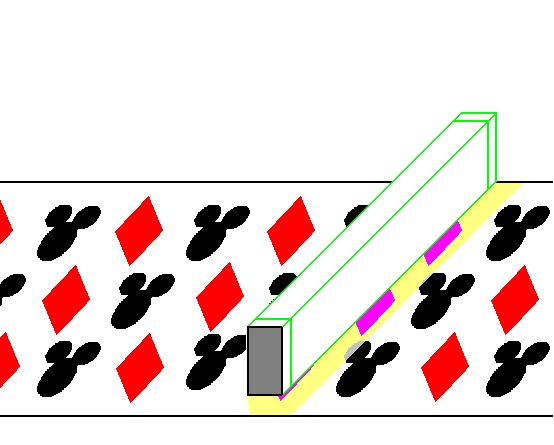

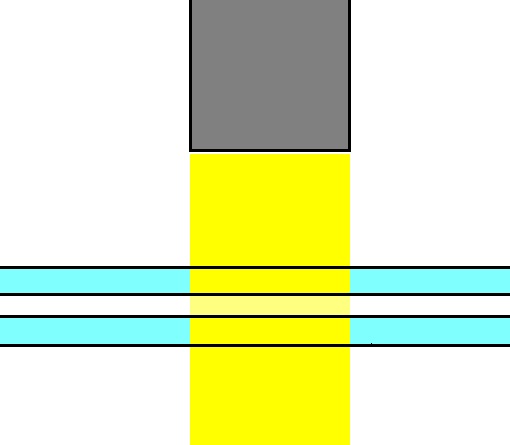

Read More »No.37 Thermal distortion check of liquid crystal

[ Problem Point ] There was no suitable one to check the thermal distortion of liquid crystal. [ ⇒Kaizen Point ] It was necessary to do 100% inspection and an image processing machine was adopted, so the central part was ...

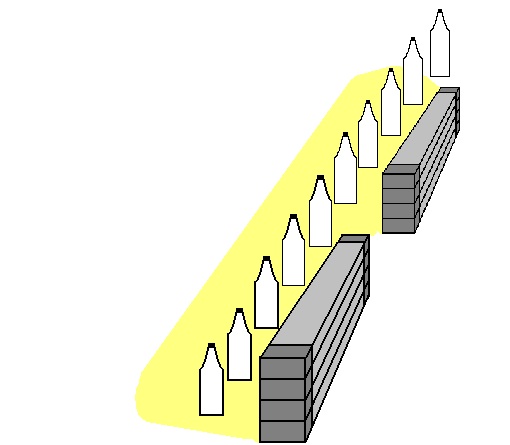

Read More »No.33 Sterilization dryness of bottle ampoule

[ Problem Point ] Glass plate couldn’t interfere and heat the inner resin in a suitable temperature. [ ⇒Kaizen Point ] Passes through the glass , it was heated by the Halogen Line Heater. The product fineness has improved because ...

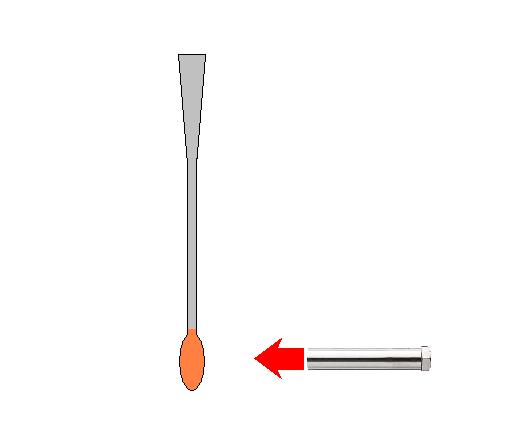

Read More »No.36 Sterilization of spatula

[ Problem Point ] Until now had been roasted in the flames of gas pipe where the gas had no trouble using the impossible. [ ⇒Kaizen Point ] The Air Blow Heater to heat sterilization at high temperatures. If it ...

Read More »No.32 Dryness of medicine pellet

[ Problem Point ] Glass plate couldn’t interfere and heat the inner resin in a suitable temperature. [ ⇒Kaizen Point ] Passes through the glass,it was heated by the Halogen Line Heater. The product fineness has improved because the temperature ...

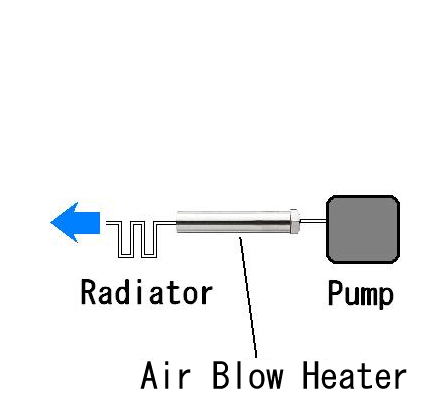

Read More »No.35 Manufacturing of heating sterilization air

[ Problem Point ] Until now we had a filter on the decontamination of heavy equipment. [ ⇒Kaizen Point ] The Air Blow Heater to heat sterilization. So small,now can be used anywhere in the air sterilization.

Read More »No.31 Dryness of triturate

[ Problem Point ] We have no idea about how to lead-free soldering of printed circuit boards. [ ⇒Kaizen Point ] Passes through the glass , it was heated by the Halogen Line Heater. The product fineness has improved because ...

Read More »No.34 Partial heating of the culture medium

[ Problem Point ] The thermostat tank is used so far,so partial heating of a culture medium isn’t done. [ ⇒Kaizen Point ] The spot was heated by the Air Blow Heater. Differential expression changes in the growth of species ...

Read More »No.30 Heating bacteria sterilization of medical supply made of the glass

[ Problem Point ] Glass plate couldn’t interfere and heat sterilization the inner bacteria in the suitable temperature. [ ⇒Kaizen Point ] Passes through the glass , it was heated by the Halogen Line Heater. The product fineness has improved ...

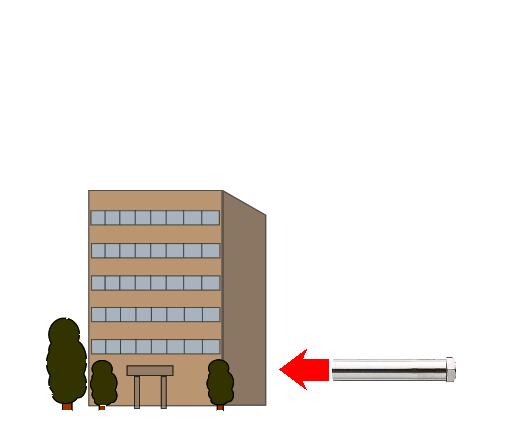

Read More »No.33 Bonding strength test of tile building

[ Problem Point ] We were in trouble because we couldn’t do the heat cycle test by the real thing so far. [ ⇒Kaizen Point ] The test point was heated by the Air Blow Heater. Heat cycle testing could ...

Read More »No.29 Dryness of printing

[ Problem Point ] We have no way to small length=2.5m quickly high temperature heater. [ ⇒Kaizen Point ] The start was early and the process became smooth. The product fineness has improved because the temperature is changed by the ...

Read More »No.32 Working test of thermo switch

[ Problem Point ] We were in trouble about the former jig because we couldn’t test in multiple steps at the site. [ ⇒Kaizen Point ] Several step of temperature was heated by the Air Blow Heater and it was ...

Read More »No.28 Preheating and heating of bonding of reversible cloth

[ Problem Point ] We have no way to small length=2.5m quickly high temperature heater. [ ⇒Kaizen Point ] Heated by the Halogen Line Heater reversible cloth. It is attached to the narrow place, and got cold so quickly, safety ...

Read More »No.31 Surface Analysis of Materials

[ Problem Point ] The sample was too big,and it couldn’t be stored in the thermostat tank,and we were in trouble. [ ⇒Kaizen Point ] The test point was heated by the Air Blow Heater. Heat cycle testing could be ...

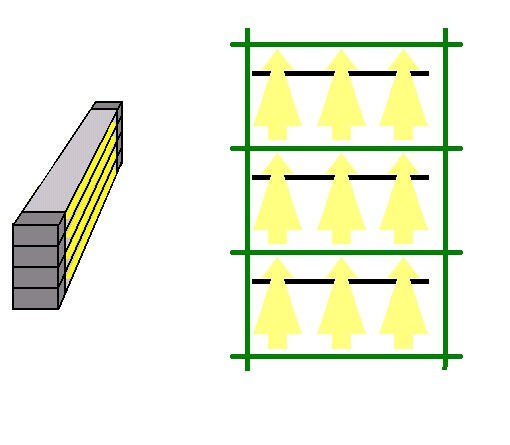

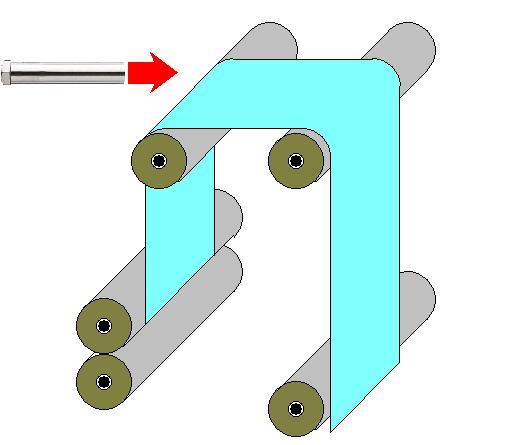

Read More »No.27 Dryness of preshrunk resin finishing of fiber (cloth)

[ Problem Point ] Rising of the heater is slow,it couldn’t balance with coating of shrink-proofed resin. [ ⇒Kaizen Point ] Dried by the Halogen Line Heater after coating fabric. Since the maximum temperature heated up in 5sec, immediately after ...

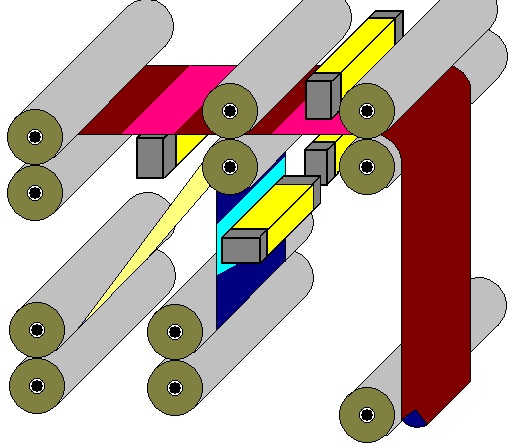

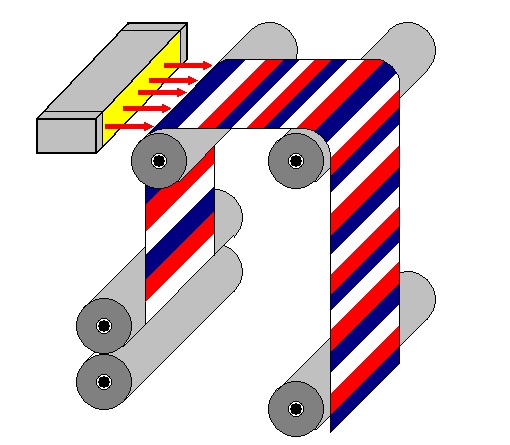

Read More »No.30 Preheating of calendaring roll

[ Problem Point ] When it was worked in the calendaring roll which got cold,horizontal stripes occurred. [ ⇒Kaizen Point ] Calendaring roll was preheated by the Air Blow Heater. Horizontal-striped occurrence was prevented.

Read More »No.26 Dryness of moisture of fiber (cloth)

[ Problem Point ] Rising of the heater is slow,therefor it can’t correspond to work of the special express job. [ ⇒Kaizen Point ] Dried by the Halogen Line Heater after soaping the dyed fabric. Since the maximum temperature heated ...

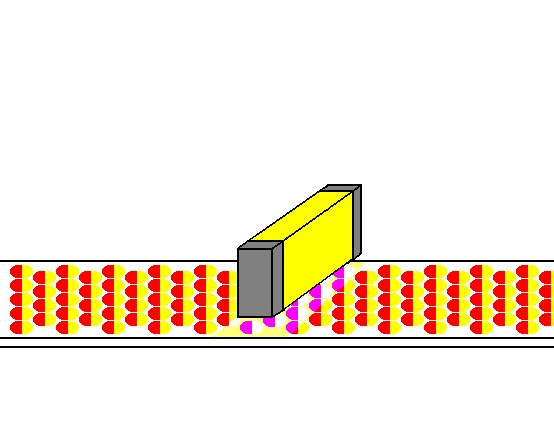

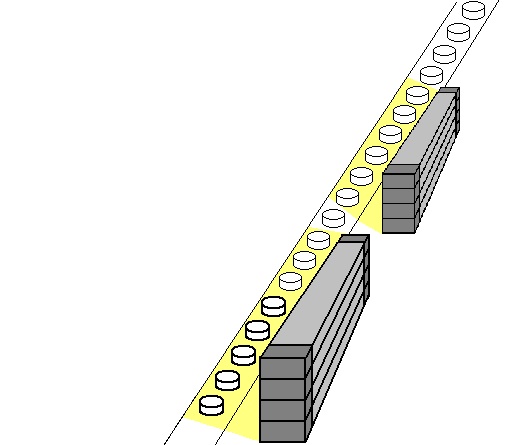

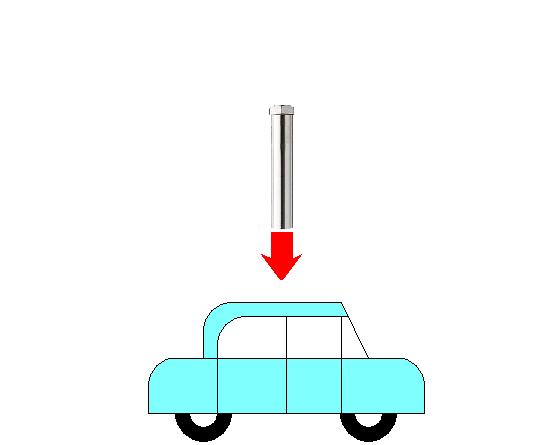

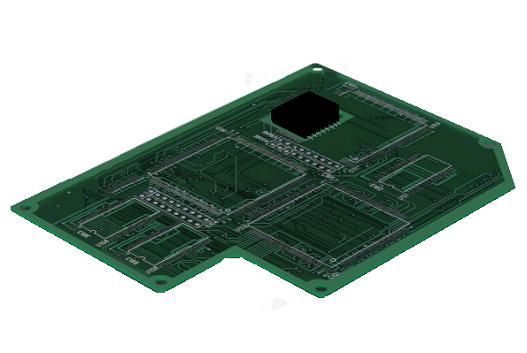

Read More »No.29 Preheating of printed circuit board

[ Problem Point ] Gluing of lead free solder would be a problem badly. [ ⇒Kaizen Point ] The small spot was preheated by the Air Blow Heater. After preheating, gluing of solder became good. Moreover it was also heat ...

Read More »No.25 Resin reinforcement sticking of the stiffening glass together

[ Problem Point ] Glass plate couldn’t interfere and heat the inner resin in suitable temperature. [ ⇒Kaizen Point ] Passes through the glass , it was heated by the Halogen Line Heater. The product fineness has improved because the ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop