[ Problem Point ] Over time the molten adhesive is applied to the box,the box was also open to poor adhesion. [ ⇒Kaizen Point ] The remelting of the hot-spot heating with the Air Blow Heater And good adhesion, the ...

Read More »No.4 Curing of gravure offset printing

[ Problem Point ] Had trouble to low power of the heater. [ ⇒Kaizen Point ] It has cured by using 4 Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could ...

Read More »No.4 Joint of thermoplastic resin tubes

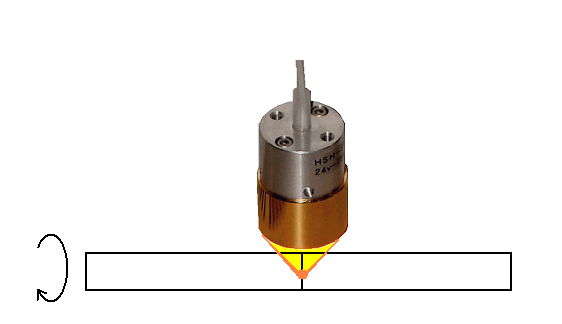

[ Problem Point ] We have no idea about how to joint of thermoplastic resin tubes. [ ⇒Kaizen Point ] The thermoplastic resin tube was joined with the Halogen Point Heater. The heating melt was done, and the central portion ...

Read More »No.5 Heat-shrinkable tubing

[ Problem Point ] We were in trouble about a dryer for industry because devices burned out because the area was too wide. [ ⇒Kaizen Point ] We heated only a lead by a small spot by the Air Blow ...

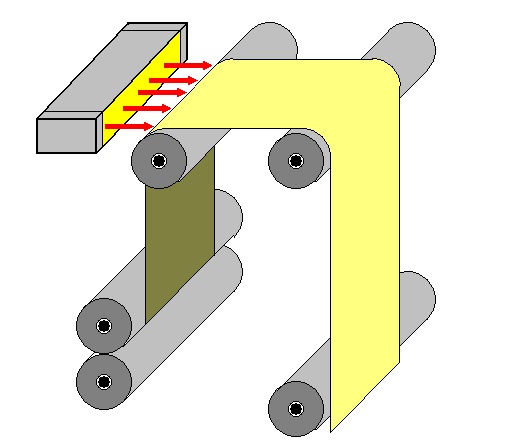

Read More »No.3 Dryness of paper-coating process

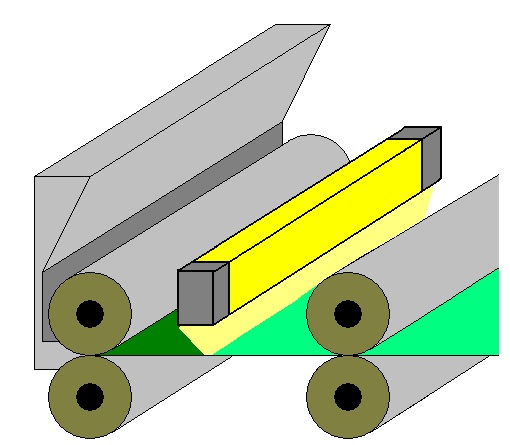

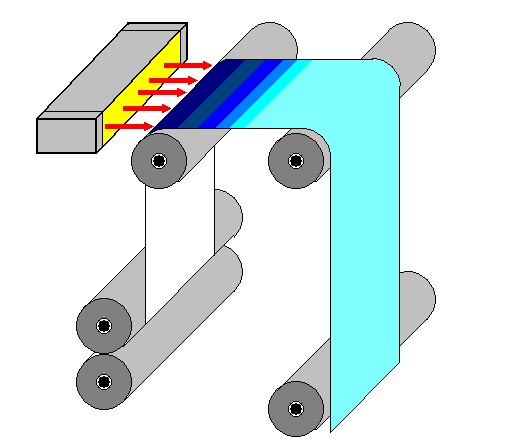

[ Problem Point ] Had trouble without the location of the heater. [ ⇒Kaizen Point ] It was dry with 2M one Halogen Line Heater. Strong light, enough output was able to be secured even in the small place. Since ...

Read More »No.3 Burning in low oxygen density environment

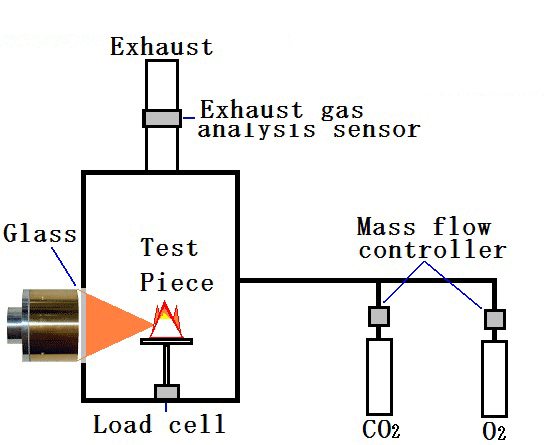

[ Problem Point ] We have no idea about how to burning in low oxygen density environment. [ ⇒Kaizen Point ] The radiant heat was given with the Halogen Point Heater. The gas analysis in the burning gas became possible ...

Read More »No.4 Film shrink

[ Problem Point ] Dryer for industry was being used. Without being made,accurate temperature control would be a problem. [ ⇒Kaizen Point ] We can control the accurate temperature by the Air Blow Heater, so wrinkles and a spot of ...

Read More »No.2 Dryness of medicine of paper-forming process

[ Problem Point ] Had trouble to difficult temperature management of the heater. [ ⇒Kaizen Point ] It was dry with the Halogen Line Heater. The quality has improved because the temperature steady by the voltage regulation was able to ...

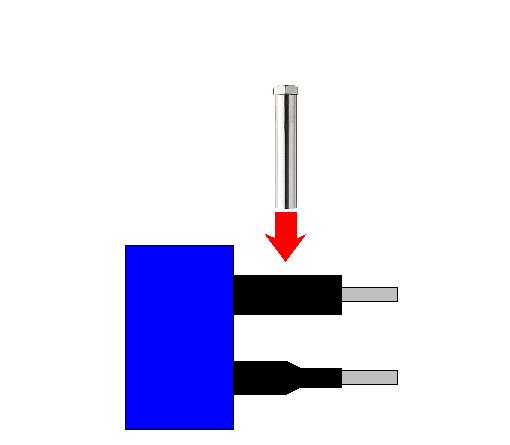

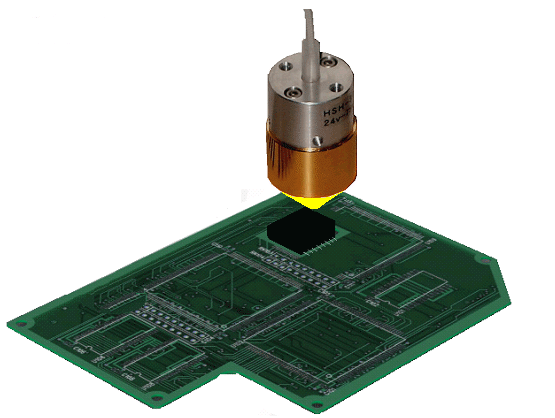

Read More »No.2 Preheat of printed circuit boards

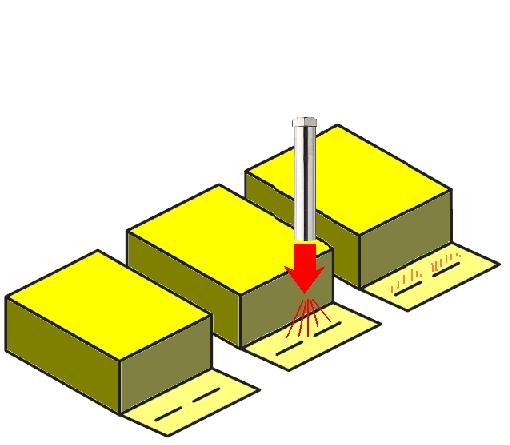

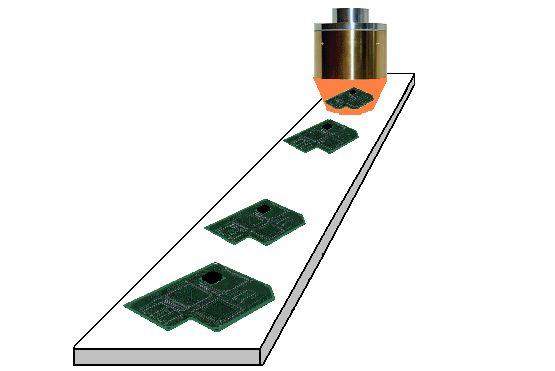

[ Problem Point ] We have no idea about how to preheat of printed circuit boards. [ ⇒Kaizen Point ] Preheated and out of focus the Halogen Point Heater. Elevating the temperature time is short, it worked so easy soldering ...

Read More »No.3 Cap Seal

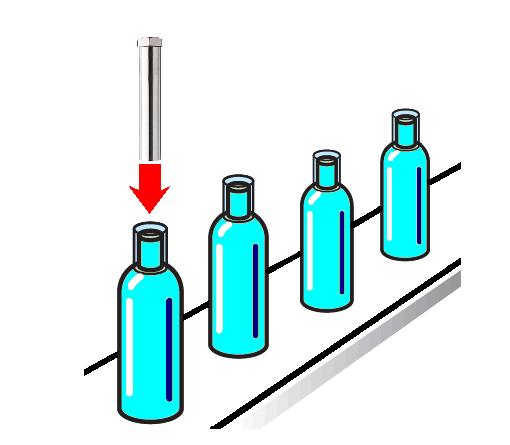

[ Problem Point ] Dryer for industry was being used. Without being made, accurate temperature control would be a problem. [ ⇒Kaizen Point ] We can control the accurate temperature by the Air Blow Heater, so wrinkles and a spot ...

Read More »No.1 Moisture control of paper-forming process

[ Problem Point ] Had trouble with slow rise of the heater. [ ⇒Kaizen Point ] Moisture flew with the Halogen Line Heater. Since the maximum temperature heated up in 5sec, immediately after the start of operation could work.The idling ...

Read More »No.1 Soldering of printed circuit boards

[ Problem Point ] We have no idea about how to lead-free soldering of printed circuit boards. [ ⇒Kaizen Point ] The point was heated by the small type of the Halogen Point Heater. Elevating the temperature time is short, ...

Read More »No.2 Processing of chocolate

[ Problem Point ] There were no tools in which chocolate is dissolved by the pinpoint, and We were in trouble. [ ⇒Kaizen Point ] A pen heater was made using an extraordinarily the Air Blow Heater We could give ...

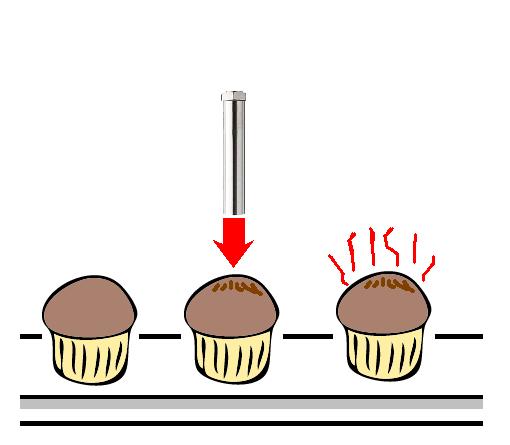

Read More »No.1 Coloring of the cake baking

[ Problem Point ] When the baking color was put,the smell of the gas shifted,so we were in trouble about gas. [ ⇒Kaizen Point ] The spot was heated by the Air Blow Heater and the baking color was put.The ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop