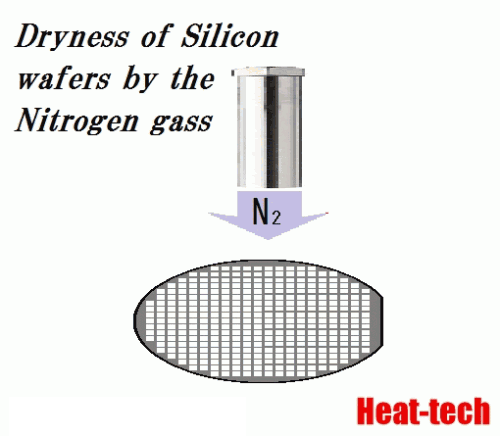

[ Problem Point ] The marks of water drop remained and were worrisome when natural drying was carried out. [ ⇒Kaizen Point ] Nitrogen was heated with the Air Blow Heater and it dried. The marks of water drop were ...

Read More »No.77 Heating of tungsten material

[ Problem Point ] When processing the wire produced by powder metallurgy,it had trouble to cracking or cutting. [ ⇒Kaizen Point ] So brittle,while heating to the processing 400 ℃ – 700 ℃ by the Air Blow Heater. The quality ...

Read More »No.76 Argon gas heating

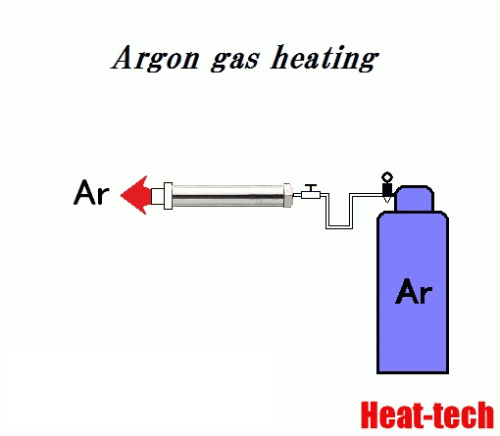

[ Problem Point ] It wasn’t possible to make hot argon gas while keeping the purity. [ ⇒Kaizen Point ] Argon gas was heated by the Air Blow Heater. Air did not mix and the high temperature gas of 550℃ ...

Read More »No.75 Aging of Printed Circuit Board

[ Problem Point ] We have no idea about how to no-contact heating in line. [ ⇒Kaizen Point ] The high temperature air of the suitable temperature was made with the Air Blow Hater and it projected. It came to ...

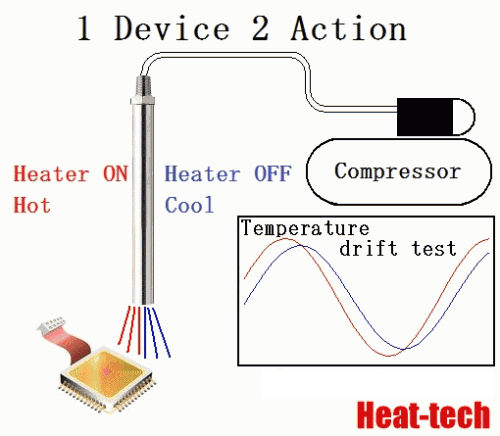

Read More »No.74 Temperature drift test of electronic device

[ Problem Point ] We have no idea about how to heating and cooling at the same time in line. [ ⇒Kaizen Point ] It made high fever air of a suitable temperature with the Air Blow Heater, projected and ...

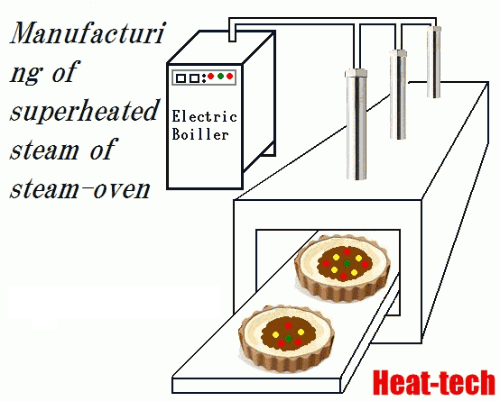

Read More »No.73 Manufacturing of superheated steam of steam-oven

[ Problem Point ] It was in trouble because the temperature of steam of the tunnel type steam-oven was not able to be adjusted. [ ⇒Kaizen Point ] Steam has overheated with the Air Blow Heater. It is possible to ...

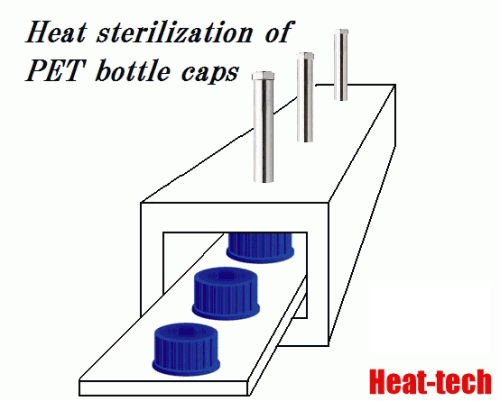

Read More »No.72 Heat sterilization of PET bottle caps

[ Problem Point ] It was in trouble because the heat resistant of the polyethylene is low. [ ⇒Kaizen Point ] The temperature of air of the heating sterilization furnace has been adjusted with the Air Blow Heater. Possible to ...

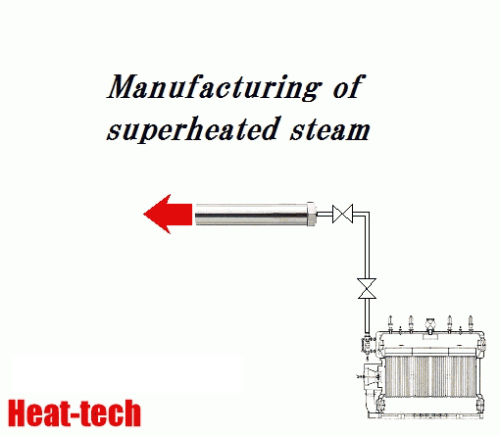

Read More »No.71 Manufacturing of superheated steam

[ Problem Point ] There was distance from a boiler,it was in trouble because the temperature of the steam fell. [ ⇒Kaizen Point ] Steam has overheated with the Air Blow Heater. It is possible to make overheating saturated steam ...

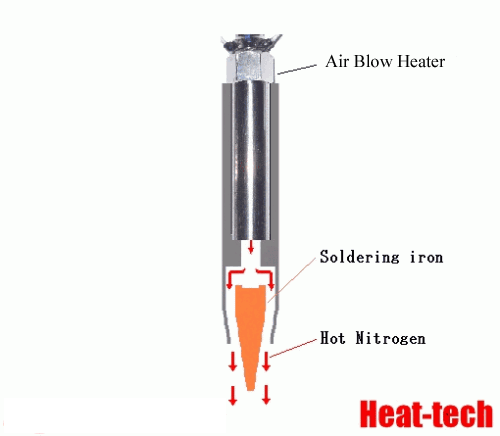

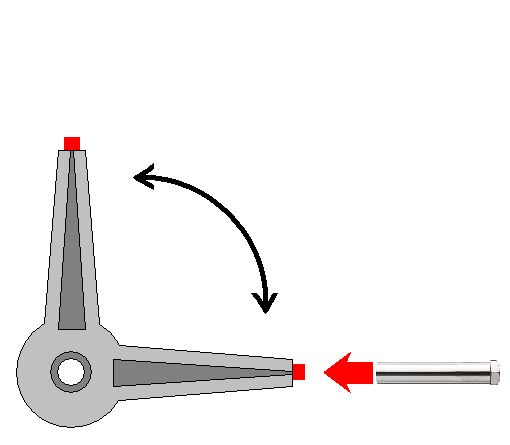

Read More »No.70 Heat source of nitrogen shield soldering iron

[ Problem Point ] It was in trouble because the priority oxidation of the tin occurred. [ ⇒Kaizen Point ] The soldering iron shielded with the nitrogen gas was made. The priority oxidation of tin is suppressed to solder in ...

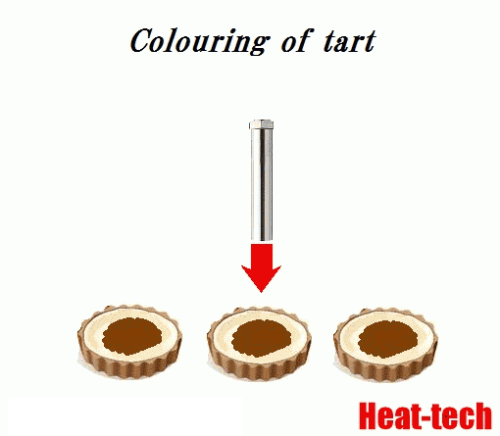

Read More »No.69 Colouring of tart

[ Problem Point ] It was in trouble because the surface of the tart burned. [ ⇒Kaizen Point ] The surface was warmed over by the Air Blow Heater. The temperature was able to be adjusted, the combustion color was ...

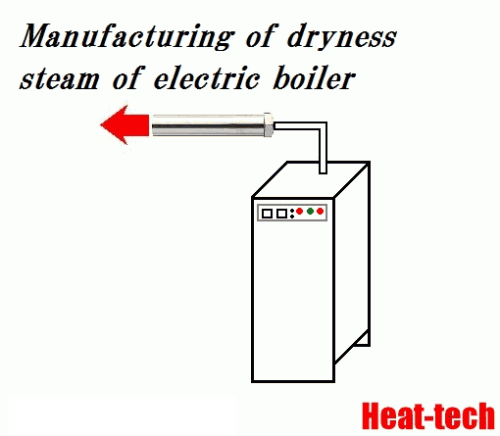

Read More »No.68 Manufacturing of dryness steam of electric boiler

[ Problem Point ] It was in trouble because the temperature of the boiler steam didn’t rise. [ ⇒Kaizen Point ] Steam was heated by the Air Blow Heater. Wet steam became dry steam.

Read More »No.67 Concentration apparatus using nitrogen gas

[ Problem Point ] We have no idea to concentrate without oxygen. [ ⇒Kaizen Point ] Nitrogen gas was blown into a sample directly and it was concentrated. The volatile low solvent like DMSO and water could also be concentrated ...

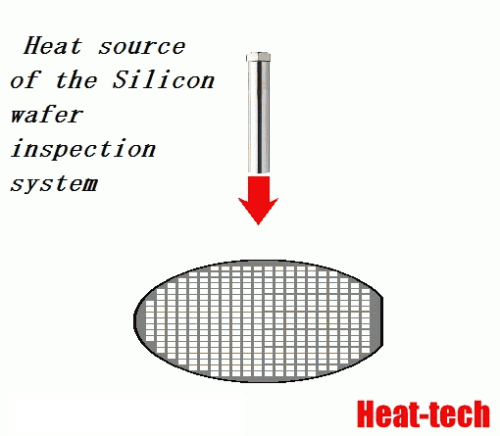

Read More »No.66 Heat source of the Silicon wafer inspection system

[ Problem Point ] We have no idea about Silicon wafer easy heating. [ ⇒Kaizen Point ] The high temperature Nitrogen gas was injected with the Air Blow Heater, and the top surface temperature was adjusted to 40O℃. The Silicon ...

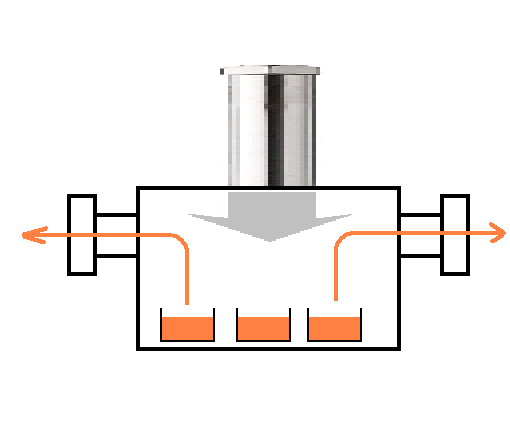

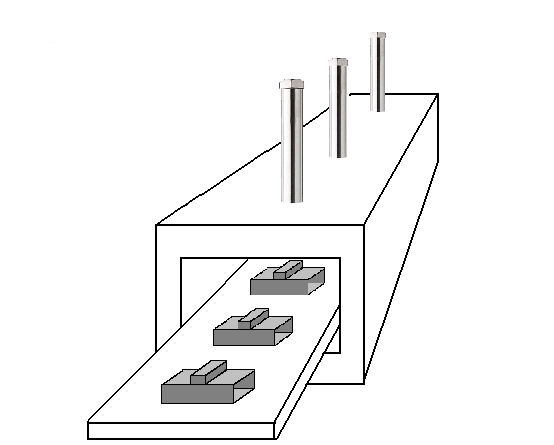

Read More »No.65 Small high-temperature tunnel furnace heat source

[ Problem Point ] There were no tools in which small high-temperature tunnel furnace heat source, and We were in trouble. [ ⇒Kaizen Point ] In a large the high-temperature heating with the Air Blow Heater capacity. Since raising the ...

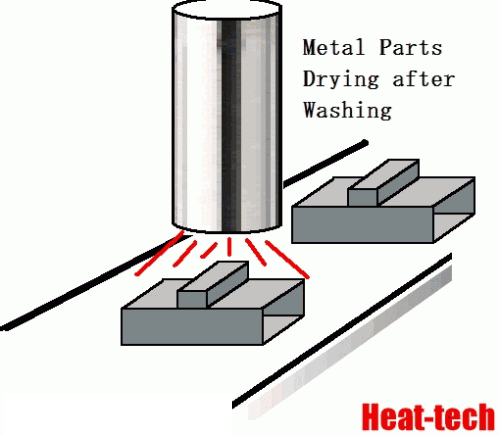

Read More »No.64 Metal Parts Drying after Washing

[ Problem Point ] There were no tools in which no fast way of drying the metal parts, and We were in trouble. [ ⇒Kaizen Point ] In a large the high-temperature heating with the Air Blow Heater capacity. Work in ...

Read More »No.63 Heating of the movable

[ Problem Point ] There were no tools in which optimum temperature for heating the moving part, and We were in trouble. [ ⇒Kaizen Point ] Heated in the Air Blow Heater. Mobility could be maintained without contact can ...

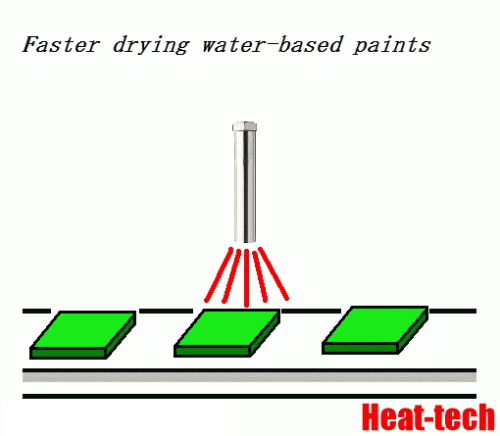

Read More »No.62 Faster drying water-based paints

[ Problem Point ] There were no tools in which quickly dry water-based paint, and We were in trouble. [ ⇒Kaizen Point ] In a large Air Blow Heater the blower at high temperature. Faster drying, increased production.

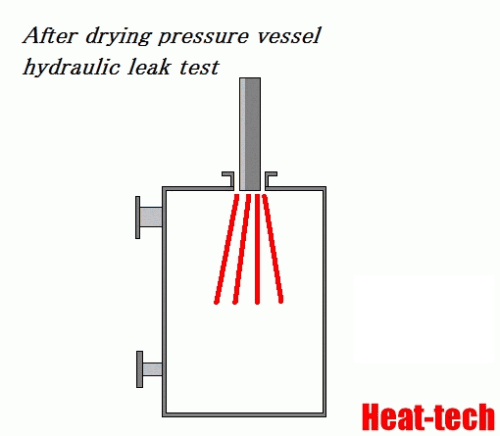

Read More »No.61 After drying pressure vessel hydraulic leak test

[ Problem Point ] If there is no way of drying the water as soon as the test was in trouble. [ ⇒Kaizen Point ] The high-temperature heating with the Air Blow Heater blower capacity. We can work faster, more ...

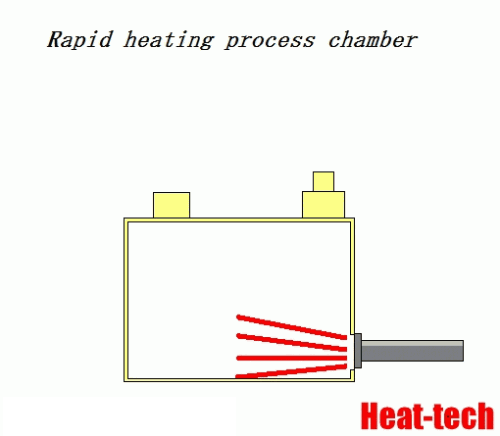

Read More »No.60 Rapid heating process chamber

[ Problem Point ] The rapid heating is not possible to the chamber, had trouble. [ ⇒Kaizen Point ] In a large the Air Blow Heater warmed rapidly. The rise of the processing cycle time, significantly increasing the number of ...

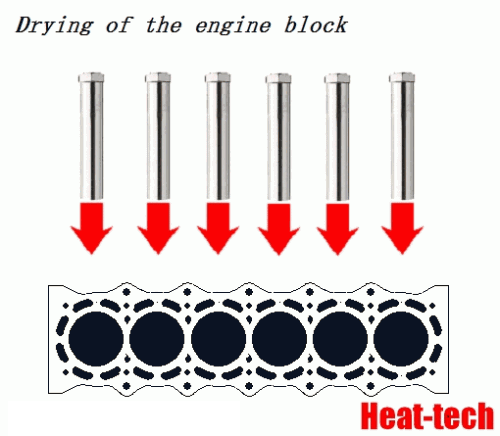

Read More »No.59 Drying of the engine block

[ Problem Point ] Flushing of chips remaining wash was in trouble. [ ⇒Kaizen Point ] In a large hot-air heating because the water flew residual. The prevention of water leakage in the next step. Eliminates the need for water ...

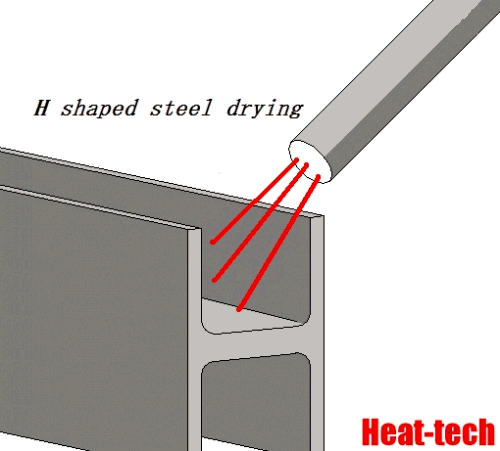

Read More »No.58 H shaped steel drying

[ Problem Point ] Liquid left after molding process was in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,it flew in the residual water and heat the air blow was coming out of rust.

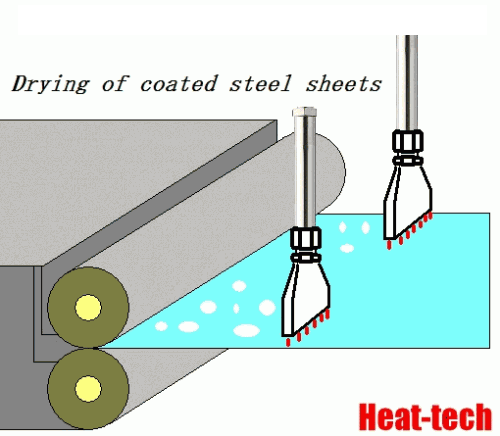

Read More »No.57 Drying of coated steel sheets

[ Problem Point ] After washing the remaining pickling was in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,it flew in the residual water and heat the air blow was coming out of rust.

Read More »No.56 Two piece feed prevention and preheat of blank material

[ Problem Point ] We were bagged and dried groceries. But there was trouble grows mold. [ ⇒Kaizen Point ] It dried heating nitrogen by the Air Blow Heater. Because nitrogen did not contain water vapor. It became the anti-mold ...

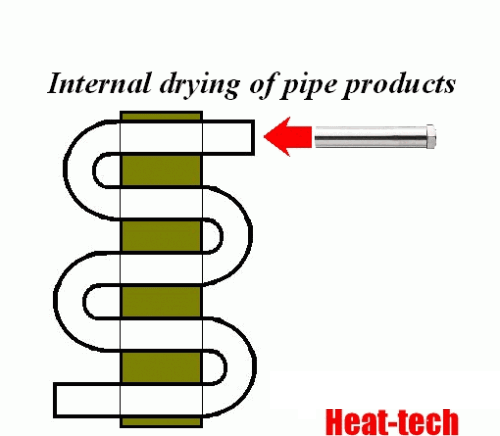

Read More »No.55 Internal drying of pipe products

[ Problem Point ] It was in trouble because Flushing cleaning solution after plumbing processing was left. [ ⇒Kaizen Point ] Rust did not go out because it had dried remaining water by the Air Blow Heater.

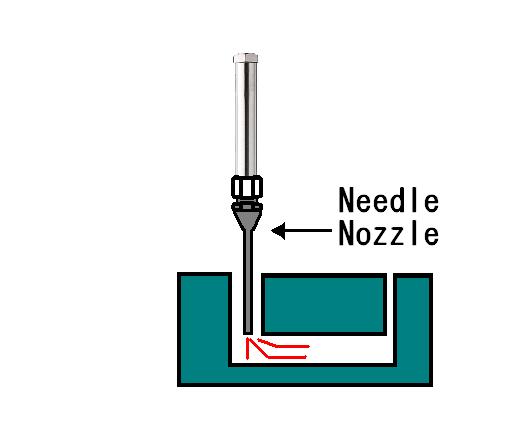

Read More »No.54 Drying of Drilled Hole

[ Problem Point ] When cleaning after cutting chips, water drops were still in trouble. [ ⇒Kaizen Point ] The Air Blow Heater,attached to the needle nozzle,dry blower. Because the hot air blower hot moment, better drying.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop