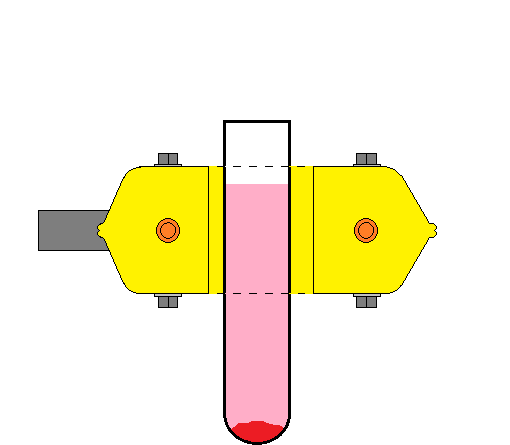

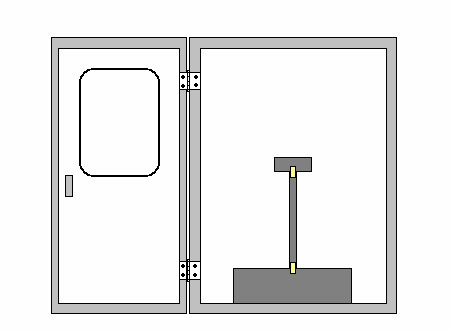

This video is a heating demonstration of wood with the halogen line heater condensing type.

Read More »Halogen Point Heater Laboratory-kit LKHPH-120FA/f45/200V-1kW +HCVD

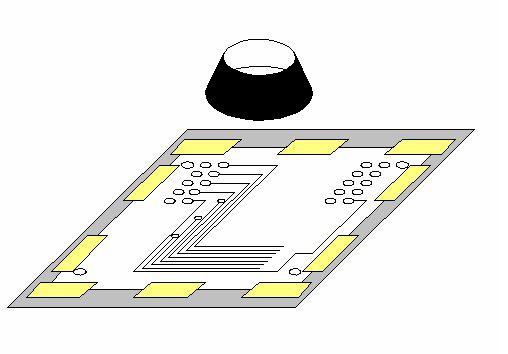

The power of 1kW is condensed to Φ21. Easily heating high temperatures! ◆ Feature ◆ Easily heating high temperatures by the kit! Easily heating 1300℃ case by max.temperature. Easily adjusting the radiation diameter (focal size) by manual lift! Easily changing ...

Read More »Halogen Point Heater Laboratory-kit LKHPH-60FA/f30/36V-450W +HCVD

Max.Temp.1400℃ Easily heating high temperatures! ◆ Feature ◆ Easily heating high temperatures by the kit! Easily heating 1400℃ case by max.temperature. Easily adjusting the radiation diameter (focal size) by manual lift! Easily changing the heat power (wattage) by slide transformer! ...

Read More »Halogen Point Heater Laboratory-kit LKHPH-35CA/f15/12V-110W + HCV

Focal sizeΦ6 Easily heating high temperatures! ◆ Feature ◆ Easily heating high temperatures by the kit ! Easily heating high temperatures at focal size Φ6 ! Easily adjusting the radiation diameter (focal size) by manual lift! Easily changing the heat ...

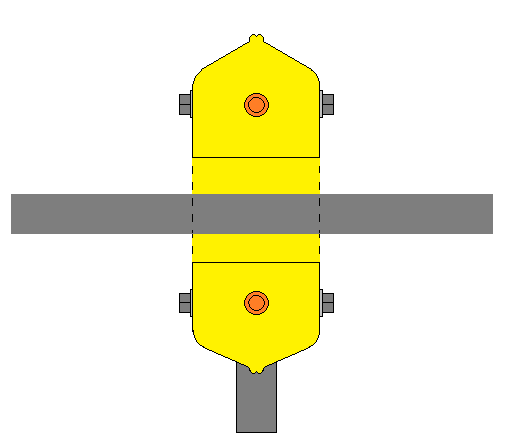

Read More »No.15 Heat sterilization

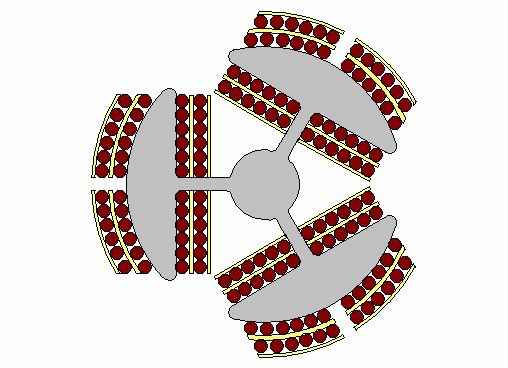

[ Problem Point ] There is no good way to sterilization in the dry and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. Since it only inserted from the feed ...

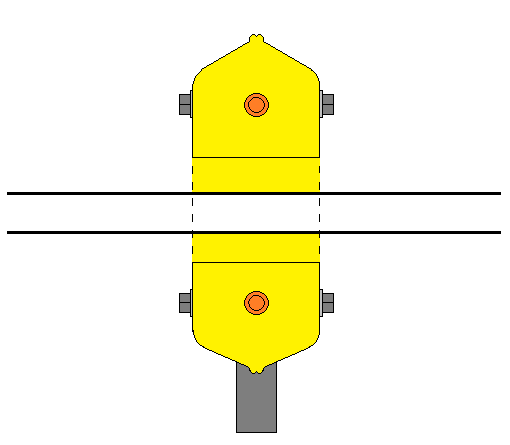

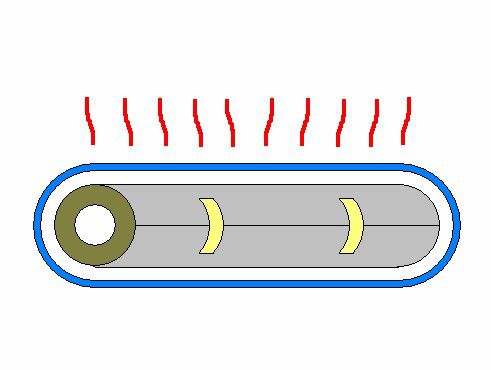

Read More »No.14 Heating of a glass pipe

[ Problem Point ] There is no good method of observing the process of heating. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was smoothly heated in a ...

Read More »No.13 Heating of a pipe

[ Problem Point ] There was no good method of carrying out high temperature heating of the pipe. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was smoothly ...

Read More »No.17 Memos in the high-temperature chamber

[ Problem Point ] Write notes to the sample in the test, It was in trouble if there is no heat resistance on scratch paper. [ Kaizen Point ] Use the ToughTape, wrote a memo in magic from above. Notes ...

Read More »No.16 Attachment of a film (mask) at the time of exposure and printing.

[ Problem Point ] In order that there might not be heat resistance and radiation resistance in a mask stop tape, when it exposed several times, distortion arose. [ Kaizen Point ] The mask stop was carried out on the ...

Read More »No.15 Insulation protects the hard disk

[ Problem Point ] The insulation for protecting from the mistake touch under assembly is required. [ Kaizen Point ] Insulated protection was carried out on the Toughtape. Reliability improved by the sufficient insulation and radiation resistance of PEEK resin.

Read More »No.14 Motor and Transformer interlayer insulation

[ Problem Point ] A pole crosses between the commutator fragment of rotter, time, it was in trouble about degradation early stage of a interlayer insulation thing by impulse wave discharge. [ Kaizen Point ] Insulated protection was carried out ...

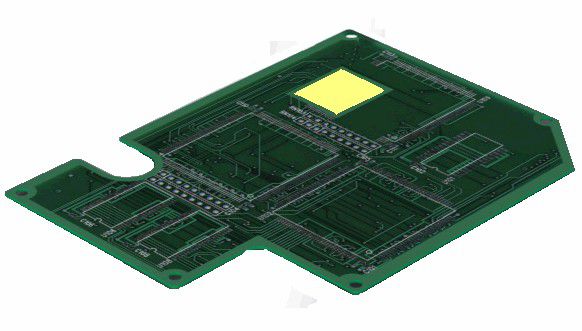

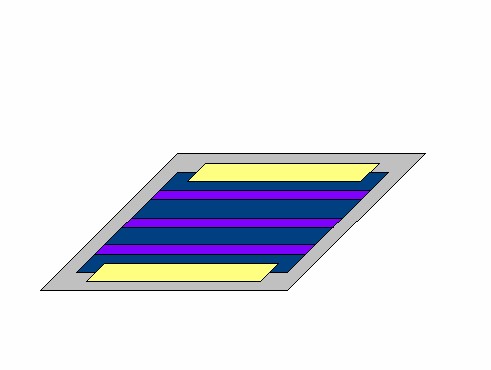

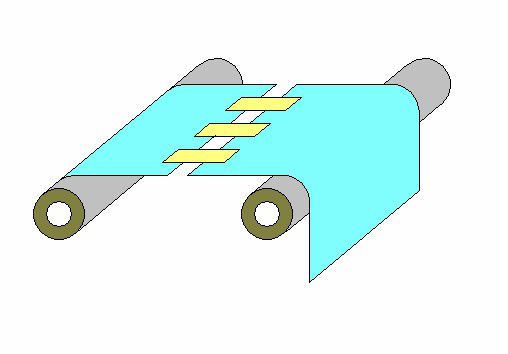

Read More »No.13 Flow and reflow soldering process for printed circuit board, masking the Gold Plate Contact

[ Problem Point ] Heat resistance is required to protect a golden terminal from cream solder. [ Kaizen Point ] The Toughtape was used and masked. It is improvement in reliability at sufficient heat resistance.

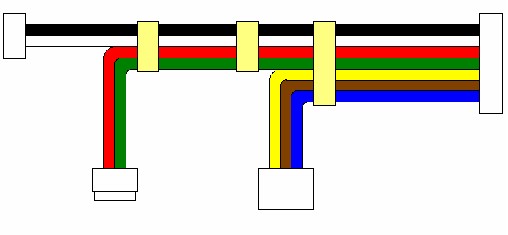

Read More »No.12 Solidarity and splices that require tensile bond strength

[ Problem Point ] Degradation would be a problem early for a high fever near the engine. [ Kaizen Point ] It banded together using the Toughtape corresponding to 260 ℃ of high fever. Since after heating has stable adhesive ...

Read More »No.11 Temporary fixing of aging heat and cycle test examination process

[ Problem Point ] The inside of a constant temperature bath cannot perform a temporary attachment in a high fever. [ Kaizen Point ] The temporary attached by the Toughtape. Work became easy and working efficiency increased.

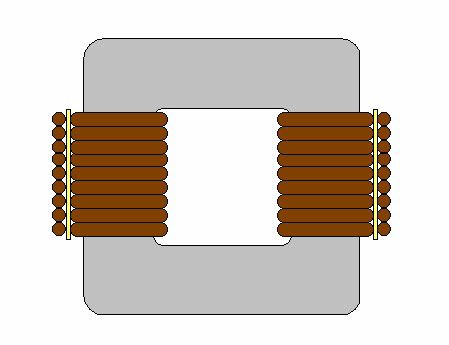

Read More »No.10 Outer stop winding and interlayer insulating transformers and coils

[ Problem Point ] The quality of an insulator needs to be inserted because of rare short prevention. [ Kaizen Point ] Insulated protection was carried out on the Toughtape. Reliability improved by sufficient insulation and radiation resistance.

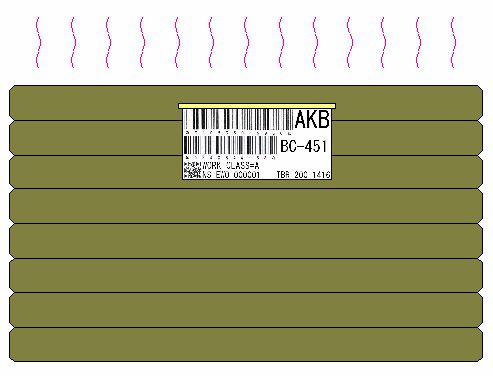

Read More »No.9 Attachment of in-company Kamban of a heat-resistant board

[ Problem Point ] High fever immediately after production, Kanban can not be pasted. [ Kaizen Point ] Kanban is pasted on Toughtape. Kanban production system expression fill the gap.

Read More »No.8 Temporarily sealing of steam sterilization

[ Problem Point ] A weather strip did not go well, but water infiltrated into sterilizing an instrument in steam. [ Kaizen Point ] That the seal-up in Toughtape. A weather strip did not go well, but water infiltrated into ...

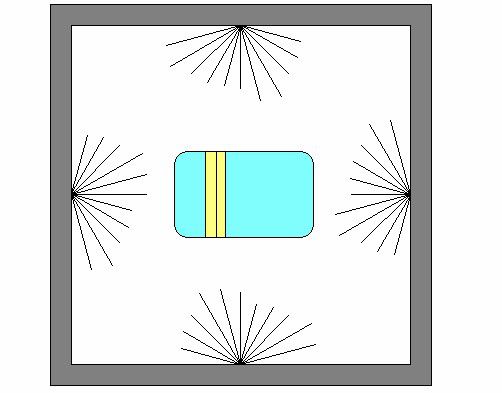

Read More »No.7 Fixed position of the exposure apparatus

[ Problem Point ] The position shifted and it was troubled by the exposure examination. [ Kaizen Point ] The temporary attached by the Toughtape. The shape is strong in 260 ℃ of permanent heat-resistance and radiation, and stable, so ...

Read More »No.6 Temporary fixing of boiler construction

[ Problem Point ] Instrument could not be fixed temporarily during construction of the boiler [ Kaizen Point ] The temporary attached by the Toughtape. Because the shape is stable and resistant to heat and humidity of a permanent 260 ...

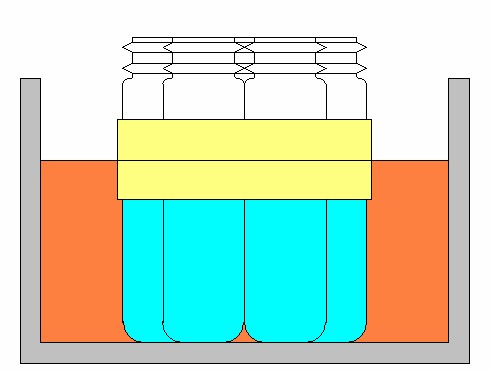

Read More »No.5 Scald the vial

[ Problem Point ] I was in trouble because it wasn’t possible to stand outside the Viola bottle against not to cork and to boil. [ Kaizen Point ] Bundle with the Toughtape. Because the shape is stable and resistant ...

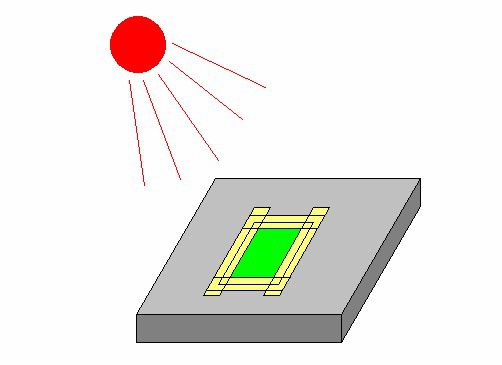

Read More »No.4 End stop of a solar panel

[ Problem Point ] It takes time before glue dries. [ Kaizen Point ] The solar panel was stopped on the frame on the Toughtape. Since the lasting heat resistance of 260 ℃ and form are stable, fixation is possible ...

Read More »No.3 End stop before heat shrinking of cloth

[ Problem Point ] For lack of heat resistance, splice unsuccessful. [ Kaizen Point ] It was spliced using the Toughtape.The shape was stable by 260 ℃ of resistance to distortion at high temperatures, so splice work became smooth, and ...

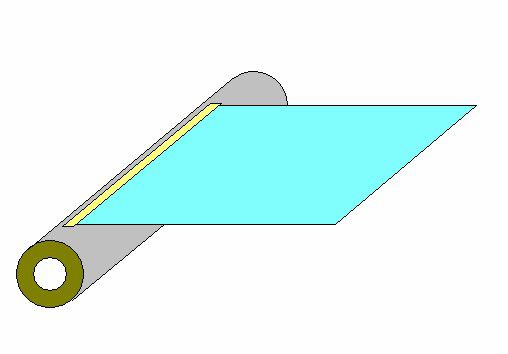

Read More »No.2 End surface of the film take-up fixed

[ Problem Point ] The end stop tape dissolved for thermal storage of a film, and poor adherence occurred for the product. [ Kaizen Point ] The end stop was carried out on the Toughtape. Since form was stable in ...

Read More »No.1 Splicing and connecting the film

[ Problem Point ] For lack of heat resistance, splice unsuccessful. [ Kaizen Point ] It was spliced using the Toughtape. The shape was stable by 260 ℃ of resistance to distortion at high temperatures, so splice work became smooth, ...

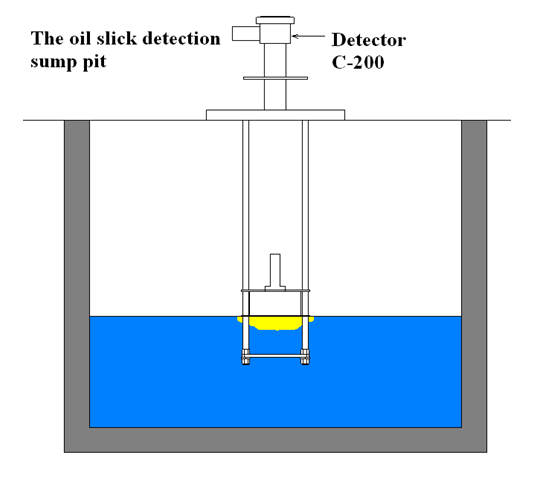

Read More »Water Surface Oil Film Detector C-200

Relay Output and Detect Oil Film on the Water. Stable and can be detected in liquid shake. The power supply, DC24V, AC110/220V, AC120/240V can also be produced. Changes in the capacitance detection electrode, and water to determine the oil film. ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop