INDEX

1.할로겐 라인 히터 형식 일람

그 외, 용도・목적에 따른 특주품의 제안・제조도 가능합니다.

2. 기종 선정의 방법

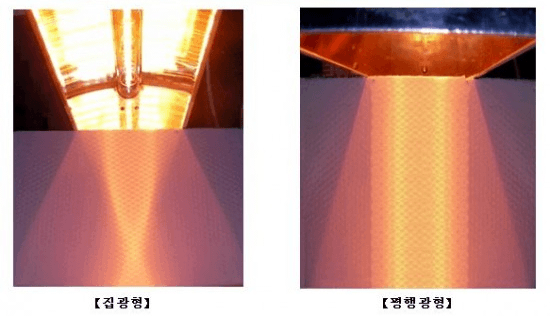

2-2 면 가열

3.초점 거리와 조사 폭

4.할로겐 라인 히터의 특징

4-1.고온 가열, 5 초 만에 1000 ℃ 로 승온합니다!

전기에서 방사 에너지 변환 효율이 높고,

할로겐 램프의 빛을 한 점에 집중 시키면1250 ℃에 도달 온도가 나옵니다.

4-2.순간 가열, 가열 시간 단축을 할 수 있습니다.

LH는 대량의 열을 광속으로 전달하기 위해 장치의 소형화, 가열 시간을 단축할 수 있습니다.

지금까지 공회전 30 분 걸려 있던 것이 공회전 시간은 제로로 할 수 있습니다.

절약 온도 지연 시간이 없기 때문에 손을 대기 시간의 낭비를 생략합니다.

온난 화가 빠르기 때문에, 유휴 상태일 때 전원 OFF 수 있습니다. 에너지 절약으로 전기 요금을 절약할 수 있습니다.

전기 사용 요금도 하루, 30kW x 0.5h x 12.16 = 182.4 원 비용 절감

또한 연간 (250 일 가동)에서 C02의 연간 배출량도 1500kg 감소!

* CO2 배출 계수는 0.4kg-CO2/kWh로 계산했습니다.

4-3.유리 너머의 가열 수 있습니다.

석영 유리는 가시 광선과 근적외선 영역에서는 투과율은 93 %. 반사 7 %입니다.

유리 너머로, 진공 중 · 불활성 가스 분위기에서도 가열 작업이 가능합니다.

4-4.정밀 온도 제어가 가능합니다.

온도는 공급 전압은 상온에서 최고 온도까지 모든 컨트롤 가능합니다.

4-5.깨끗합니다.

빛으로 비접촉 가열하기 때문에 완전히 깨끗한 가열 및 진공 상태에서 가열이 가능합니다.

4-6.장수명 화가 가능합니다.

램프 수명은 공급 전압에 의해 통상 수명에 수명까지 임의로 컨트롤 가능합니다.

윗 그림처럼, 정격 전압으로부터 10% 내리고 사용하면, 설계 수명이 3배에 성장합니다.

정격 전압으로부터 20% 내리고 사용하면, 설계 수명이 9배에 성장합니다.

4-7.안전성이 우수합니다.

인체에 비교적 안전한 가열 장치입니다.

석영 유리이므로 먼지와 가스의 발생이없이 편안하게 작업할 수 있습니다.

또한 문제 때 히터 강 온도가 빠르기 때문에, 피가 열 물의 염증의 위험이 줄어 듭니다.

4-8.특주 대응합니다.

*할로겐 램프의 빛의 파장은 약 1μm를 피크로하는 0.4 – 2.5μm 영역 (가시 광선-적외선 영역)입니다.

*반투명 체 (피부와 페인트와 접착제 등)는 비교적 내부까지 들어가 내부에서도 가열된다.

*금속에 대한 흡수율이 원적 외광보다 좋고, 비금속에 대해서는 좋지 않은 물건도 차이가 많이 나옵니다.

5.기본 구조

냉각 팬 탑재 형

수냉 형

6.히터 컨트롤러와 제어 방식

6-1.수동 제어 → HCV 시리즈

할로겐 히터 용 수동 전원 컨트롤러 HCV 시리즈의 개요로 이동

6-2.자동 온도 제어 → HHC2 시리즈

6-3.계단 제어 → SSC 시리즈

7.적외선 흡수율

이 표에 적외선 흡수율을 확인합니다.

대충 0.5 = 50 % 이상 흡수하는 물질이 원적외선 가열에 적합합니다.

할로겐 빛의 특성

유기물의 적외선 흡수율

무기물의 적외선 흡수율

귀금속 · 중금속 · 유색 금속의 적외선 흡수율

희토류의 적외선 흡수율

자성 금속의 적외선 흡수율

8.안전상의주의 사항 (중요)

1.할로겐 램프의베이스 부 램프 부등는 통전 중 및 통전 직후에는 매우 고온이됩니다.

화상이나 화재 등의 원인이되지 않도록주의하십시오.

또한 집광 부 가까이 공간도 매우 고온이되므로, 같은주의가 필요합니다.

2.할로겐 램프와 같은 고압 넣기 유리 전구가 폭발할 위험이 있습니다.

파열하면 고온 (600 ℃ 이상) 석영 유리가 비산하기 때문에 매우 위험합니다.

파열은 대부분의 경우 필라멘트가 단선 후 램프 내부에서 아크 방전이 발생하고 그에

따른 고온에서 내부 압력이 상승하여 파열합니다.

또는 아크 방전에 의한 높은 전류에서 몰리브덴 포일이 타서 끊어져 그 때 석영 유리가

깨져 램프가 파열합니다.

특히 램프 파열은 필라멘트 단선시 아크 방전이 일어나는 고전압 램프 나타나기

쉬우므로주의하시기 바랍니다.

3.이 위험을 회피하기 위해서는 파열되어도 화재나 등에 위험이 없도록 설계된기구에서,

조건에서 사용하십시오. 또한 전원 라인에는 적절한 속단 FUSE를 삽입하십시오.

4.할로겐 램프의 불빛에는 미량이지만 인체에 유해한 자외선도 포함되어 있습니다.

(태양광의 1 / 10 정도) 때문에 장시간 높은 조도의 인체 등에 대한 조사는주의가

필요합니다.

또한 자외선 경화 수지의 가열 용도 등에서는 자외선 차단 필터가 필요한 경우도

있습니다.

5.자외선이 아니어도 강한 빛은 눈에 유해합니다.

점등중의 램프의 필라멘트와 스팟 히터의 빛을 모음부를 보는 경우에는 짙은

선글라스(sunglass)등으로 눈을 보호해 주십시오.

6.할로겐 히터는 적시지 마십시오. 또한 안전을 위해 본체를 접지하십시오.

7.램프 교체시 전원이 OFF되어 있는지 반드시 확인하십시오.

감전의 위험이 있습니다.