連續使用鹵素燈線加熱器總是需要冷卻。

這是因為燈封的耐熱溫度為 300°C。

避免在耐熱溫度範圍內使用,並務必冷卻。

如果在高溫下加熱,一定要冷卻,因為這會影響鹵素燈密封部分的損壞和主體的劣化,並會導致壽命。建議控制器配備安全措施,例如在切斷冷卻時關閉加熱器。

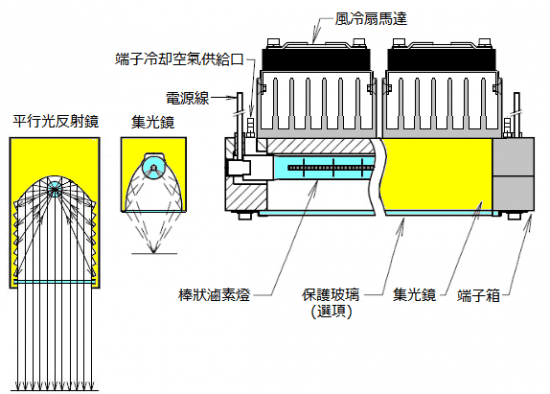

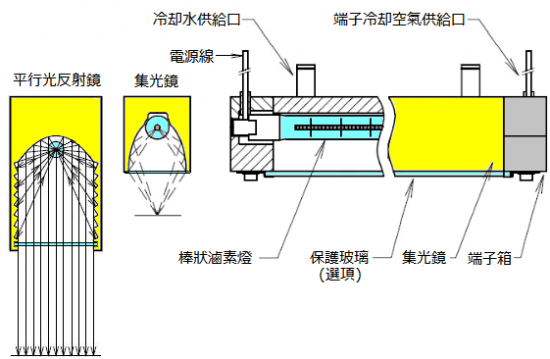

由於鹵素燈線型加熱器的結構,有兩個冷卻點,一個集光鏡部分和一個燈密封部分。

集光鏡冷卻方式

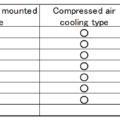

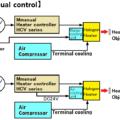

集光鏡的冷卻方式有兩種,一種是冷卻風扇安裝式,另一種是水冷式。

(1) 冷卻風扇安裝型

它只能與加熱器控制器一起使用。

冷卻風扇的電源由加熱器控制器提供。假設使用環境為室溫。

(2) 水冷式

需要加熱器控制器和冷卻器(冷卻水),但也可以在真空容器中使用。

冷卻水的最小流量為每1kW加熱器功率0.5L/min或更多。

從安全的角度來看,我們建議雙倍以上。

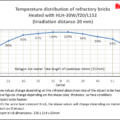

假設冷卻水溫度約為15℃。如果冷卻水過低,則可能會因結露或結露產生的水滴而導致漏電。假設壓力約為 200kPa或更低。如果超過 300kPa,請聯繫我們。

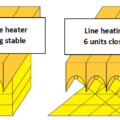

HLH-55、HLH-60 和 HLH-65 的三種型號具有兩組集光鏡,可串聯或並行選擇水冷路徑。

在6kW以下時,請串聯選擇水冷路徑。

對於 6kW 或更高,請同時選擇水冷路徑。

燈封的冷卻方式僅為壓縮空氣冷卻方式。

使用 HLH-30、HLH-35 或更高型號在高溫下加熱時,請務必始終冷卻。

密封件設計為通過彎曲鋼管進行冷卻。

打開接線盒時,如更換燈泡時,注意不要移動鋼管。

HEAT-TECH 最佳技術網店

HEAT-TECH 最佳技術網店