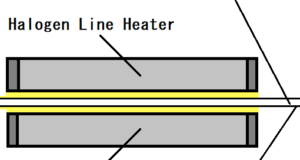

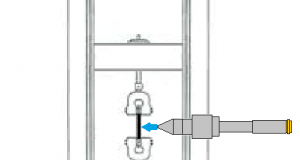

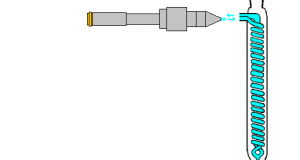

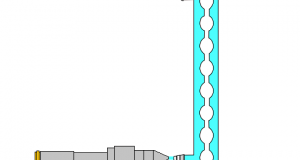

[ Problem Point ] We were looking for a heater that can heat high-pressure gas. [ ⇒Kaizen Point ] A halogen line heater is placed facing the metal pipe to heat it. Safe heating because it is in-line.

Read More »No.66 In-line heater for hydrogen gas heating

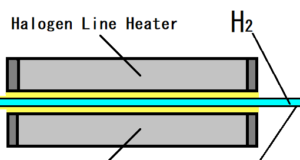

[ Problem Point ] We were looking for a heater that could safely heat hydrogen gas. [ ⇒Kaizen Point ] A halogen line heater is placed facing the metal pipe to heat it. Safe heating because it is in-line.

Read More »No.65 In-line heater for heating liquid ammonia

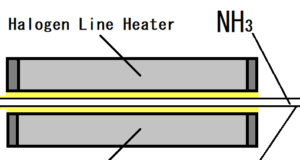

[ Problem Point ] We were looking for a heater that could safely heat liquid ammonia. [ ⇒Kaizen Point ] A halogen line heater is placed facing the metal pipe to heat it. Safe heating because it is in-line.

Read More »No.64 Inline heater for ammonia gas heating

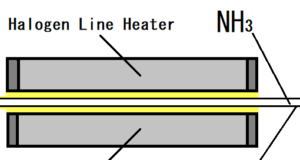

[ Problem Point ] We were looking for a heater that could safely heat ammonia gas. [ ⇒Kaizen Point ] A halogen line heater is placed facing the metal pipe to heat it. Safe heating because it is in-line.

Read More »No.18 Light source for thin-layer chromatography

[ Problem Point ] A low-cost, easy-to-use analytical method was needed. [ ⇒Kaizen Point ] It was used for pharmaceutical purity tests and follow-up confirmation tests for synthetic experiments. Fluoresces green under UV irradiation at 254 nm For detection by ...

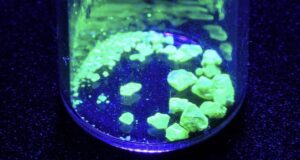

Read More »No.17 Ultraviolet fluorescence method for quantification of uranium ore

[ Problem Point ] A small amount of uranium needed to be quantified. [ ⇒Kaizen Point ] A molten material made by adding a small amount of uranium to sodium fluoride emits a yellow-green fluorescent color when exposed to ultraviolet ...

Read More »No.16 Absorptiometry light source for total protein quantification method

[ Problem Point ] In order to collect samples after measurement, an analytical method that does not use additives was required. [ ⇒Kaizen Point ] Absorbance was measured at a UV wavelength of 280 nm to quantify protein. For a ...

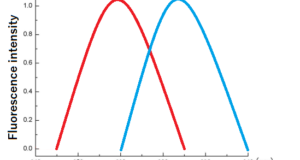

Read More »No.15 Ultraviolet fluorescence method of sulfur dioxide

[ Problem Point ] It was necessary to measure the concentration of sulfur dioxide emitted into the atmosphere. [ ⇒Kaizen Point ] Fluorescence is emitted when the SO2 molecules excited by irradiating the sample with UVC return to the ground ...

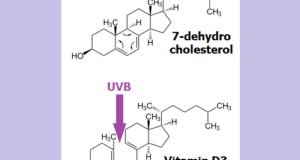

Read More »No.14 Synthesis of vitamin D by UV irradiation

[ Problem Point ] Poor health due to lack of vitamin D. [ ⇒Kaizen Point ] Exposure to ultraviolet rays (UV-B) with a wavelength of around 300 nm for about 10 minutes a day, Vitamin D was synthesized in the ...

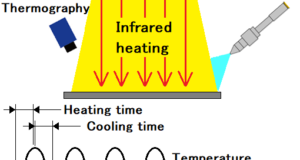

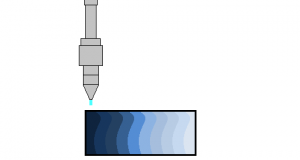

Read More »No.63 Evaluation of thermal responsiveness of thin ceramic plates

[ Problem Point ] We were looking for a heater to supplement the amount of heat dissipated from the thin plate. [ ⇒Kaizen Point ] Using a fast response halogen line heater. The accuracy of the feedback evaluation experiment has ...

Read More »No.62 Evaluation of metal heat storage material

[ Problem Point ] High speed heating was required to evaluate the responsiveness of the heat storage material. [ ⇒Kaizen Point ] Uses a halogen line heater that instantly heats up, The speed of the evaluation experiment has increased. I ...

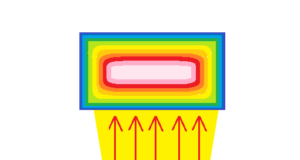

Read More »No.59 Lock-in infrared heat generation analysis-Lock-in thermography method

[ Problem Point ] We were looking for a heater that would synchronize with the pulse signal. [ ⇒Kaizen Point ] By changing the applied frequency, it was possible to limit the area of the heat generation point. When applied ...

Read More »No.13 Tensile tester low temperature setting

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.12 Reproduction of thermal distortion

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

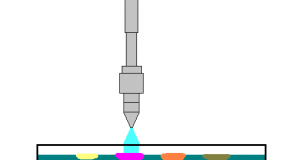

Read More »No.11 Cooling and solidification of 3D printer

《Problem Point 》 There was no good equipment to pinpoint the modeling to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

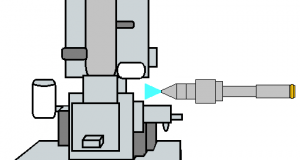

Read More »No.10 Electron microscope sample cooling

《Problem Point 》 There was no good equipment to pinpoint the sample to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

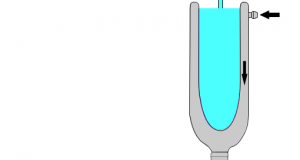

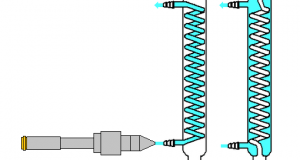

Read More »No.9 Refrigerant of Liebig condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.8 Refrigerant of Dewar condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.7 Refrigerant of Dimroth condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.6 Refrigerant of Allihn condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

Read More »No.5 Refrigerant of Graham condenser

《Problem Point 》 It was an environment where cooling water could not be used. 《⇒Kaizen Point 》 An Air Blow Cooler was used. With the combination of electricity and air, the water supply and drainage system could be omitted. Since ...

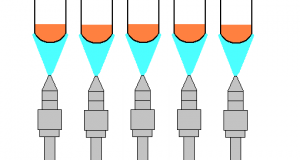

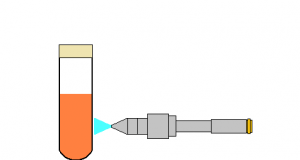

Read More »No.4 Test tube cooling

《Problem Point 》 There was no good equipment to cool the test tube. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the Air Cooler Controller, the inspection accuracy has increased.

Read More »No.3 Partial cooling of medium

《Problem Point 》 There was no good equipment to pinpoint the medium to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More »No.2 Low temperature drying of vials

《Problem Point 》 There was no good equipment for low temperature drying vials. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Since the set temperature can be maintained with the cool air cooler controller, the tact time can be ...

Read More »No.1 Vial cooling

《Problem Point 》 There was no good equipment to pinpoint the vials to a low temperature. 《⇒Kaizen Point 》 An Air Blow Cooler was used. Pinpoint cooling is possible with the needle nozzle. Since the set temperature can be maintained ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop