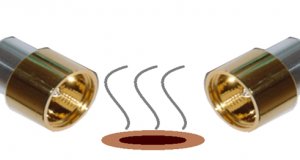

[ Problem Point ] The affinity of the metal thin film was not good. [ ⇒Kaizen Point ] The metal was heated and activated, and the affinity was improved.

Read More »No.57 Surface modification of resin

[ Problem Point ] The hydrophilicity of the resin was not good. [ ⇒Kaizen Point ] Gas was brought into contact with the resin and irradiated with a halogen line heater. A synthetic thin film was formed on the surface, ...

Read More »No.44 Thermal expansion evaluation of a special alloys

[ Problem Point ] There was no easy precision heating method for semiconductors. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature by feedback control with near ...

Read More »No.43 Thermal expansion evaluation of semiconductors

[ Problem Point ] There was no easy precision heating method for semiconductors. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature by feedback control with near ...

Read More »No.114 Simulation of smoke diffusion

[ Problem Point ] There was nothing that could heat the dummy gas at any temperature. [ ⇒Kaizen Point ] A air blow heater was used. Since there is a controller that can automatically control the temperature and hot air ...

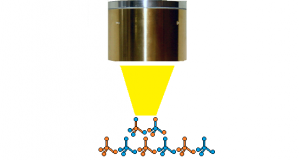

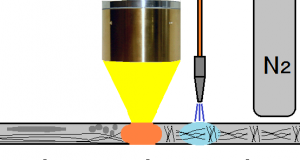

Read More »No.42 Synthesis of alloy particle

[ Problem Point ] There was no way to easily heat the metal particles to a high temperature. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Stabilized heating at an arbitrary temperature ...

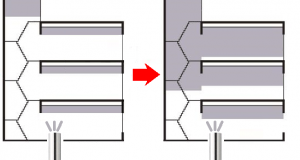

Read More »No.41 Development of crystal structure of magnetic substance

[ Problem Point ] There was no way to heat at any temperature and cool at any temperature to develop the crystal structure. [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Since ...

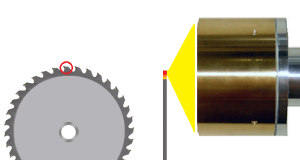

Read More »No.40 Soldering of tip saw

[ Problem Point ] There was no easy way to set the tip of the tip saw to 1000℃ [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. Since it can be processed ...

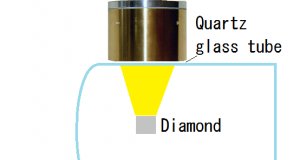

Read More »No.39 Trial manufacture of diamond quantum sensor

[ Problem Point ] There was no way to easily bring the diamond in the glass tube to 1000℃ [ ⇒Kaizen Point ] It was heated to a high temperature using a halogen point heater. The equipment became smaller and ...

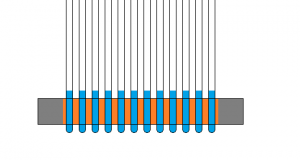

Read More »No.1 Heating of test tube

[ Problem Point ] There was not a method to heat a part of test tube in far infrared rays. [ ⇒Kaizen Point ] Heated using a far infrared line heater FLH-30. Glass and a liquid were able to heat ...

Read More »No.1 Pinpoint heating of resin

[ Problem Point ] There was no compact heater of far infrared which can pinpoint point the resin. [ ⇒Kaizen Point ] Heated using a far infrared ray point heater FPH-30. The welding of the resin got to work gently.

Read More »No.38 Experimental study on high temperature dynamic characteristics of rocks

[ Problem Point ] The creep characteristics of sedimentary soft rocks at high temperatures could not be grasped. [ ⇒Kaizen Point ] And heated at high temperature using a halogen point heater. Since it can be heated to any temperature ...

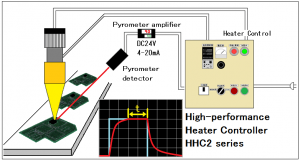

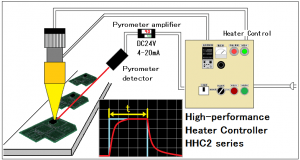

Read More »No.6 Control of a dry time for solvent system adhesive

[ Problem Point ] It took a certain amount of curing at a stable temperature without overshoot. [ ⇒Kaizen Point ] Using the heat retention time control function of highly functional heater controller HHC2. The heating time was tested in ...

Read More »No.5 Heating time control for condition setting

[ Problem Point ] It was necessary to set conditions as to whether heating could be done within the takt time. [ ⇒Kaizen Point ] Using the heat time control function of highly functional heater controller HHC2. The heating time ...

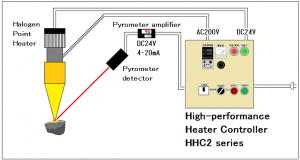

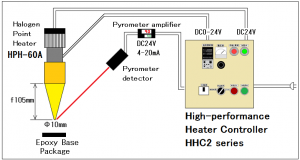

Read More »No.3 Heat dry feedback control of a Epoxy Base package

[ Problem Point ] I intended to shorten the dry time for epoxy base package, but was not able to temperature-control it by non-contact. [ ⇒Kaizen Point ] Thermocontroller for a pyrometer was mounted on the High-performance heater controller HHC2 ...

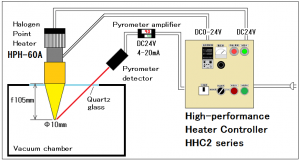

Read More »No.2 Feedback control of the halogen heater for the vacuum chamber heating

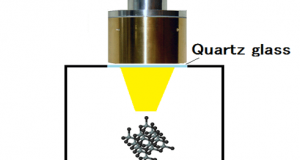

[ Problem Point ] I thought I’d like to heat a sample by a linear electron accelerator and an X-ray laser, but percent of vacuum is destroyed, so it isn’t done. [ ⇒Kaizen Point ] Heating was controlled using a ...

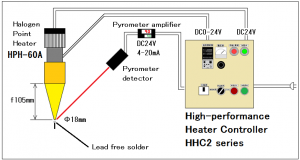

Read More »No.1 Feedback control of halogen heater for solder melting

[ Problem Point ] I thought that I would like to use a halogen heater for the remaining heat of the printed circuit board, but I could not control the temperature without contact. [ ⇒Kaizen Point ] Thermocontroller for a ...

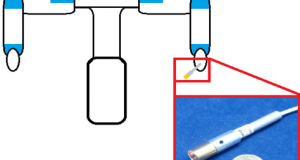

Read More »No.37 Heating processing of the double-arm robot

[ Problem Point ] There was no compact heater that can be mounted on a dual arm robot. [ ⇒Kaizen Point ] It was heated using microminiature Halogen Point Heater HPH-12. Handling became easy since it is a finger size ...

Read More »No.54 Borosilicate glass plate melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass plate was melted using a halogen line heater. The glass tube processing process was composed only by electric equipment. In addition, ...

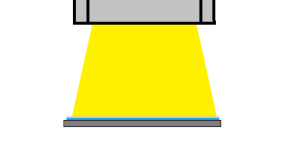

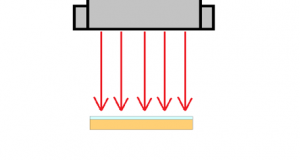

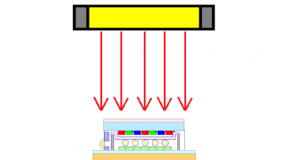

Read More »No.53 Heat test of the color filter

[ Problem Point ] It is necessary to shorten the new development time of a color filter. [ ⇒Kaizen Point ] We were using the parallel light type halogen line heater. Since the halogen heating type, it was able to ...

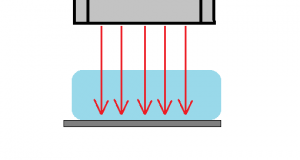

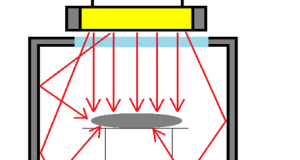

Read More »No.52 Sample heating in the vacuum chamber

[ Problem Point ] It is necessary to visually heating process. [ ⇒Kaizen Point ] We were using the parallel light type halogen line heater. Process is well understood since the heating change can be confirmed visually. We succeeded in ...

Read More »No.36 Caramel-ization of sugar

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] We made a caramel by sugar using a halogen point heater. The glass tube processing process was composed only by electric equipment. In ...

Read More »No.35 Calcination of SiC silicon carbide

[ Problem Point ] There were no sources of heat which can easily heat SiC silicon carbide. [ ⇒Kaizen Point ] SiC silicon carbide was heated using the Halogen Point Heater. As it became the high temperature in a short ...

Read More »No.34 Borosilicate glass tube melting

[ Problem Point ] There was no substitute heat source to replace gas. [ ⇒Kaizen Point ] Borosilicate glass tube was melted using a halogen point heater. The glass tube processing process was composed only by electric equipment. In addition, ...

Read More »No.104 Examination of a engine turbine

[ Problem Point ] Heating equipment of a lean air was needed. [ ⇒Kaizen Point ] Heating the turbine using the Air Blow Heater. Lean air in proportion to the law of Charles was obtained.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop