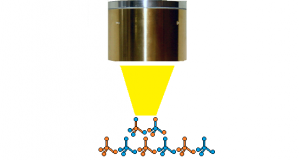

[ 문제점 ] 금속 박막의 친 화성이 좋지 않았다. [ 개선의 포인트 ] 금속이 가열되고 활성화하고 친 화성이 향상되었다.

Read More »제 57 호 플라스틱의 표면 개질

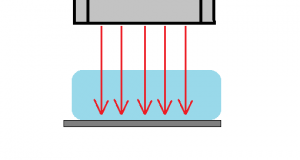

[ 문제점 ] 플라스틱의 친수성이 좋지 않았다. [ 개선의 포인트 ] 플라스틱에 가스를 접촉시켜 할로겐 라인 히터를 조사했다. 표면에 합성 박막이 형성된 친수성이 향상되었다.

Read More »제 44 호 특수 합금의 열팽창 평가

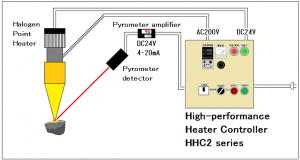

[ 문제점 ] 특수 합금를 쉽게 정밀 가열하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 고온 가열 하였다. 금속에 흡수되기 쉬운 근적외선에서 피드백 제어에 임의의 온도에서 안정 가열 하였다. 설비가 소형화 연구비를 신청 쉬워졌다. 게다가 순간적으로 고온 ...

Read More »제 43 호 반도체의 열팽창 평가

[ 문제점 ] 반도체를 쉽게 정밀 가열하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 고온 가열 하였다. 금속에 흡수되기 쉬운 근적외선에서 피드백 제어에 임의의 온도에서 안정 가열 하였다. 설비가 소형화 연구비를 신청 쉬워졌다. 게다가 순간적으로 고온 가열 ...

Read More »제114호 연기 확산 시뮬레이션

[ 문제점 ] 다미가스를 임의의 온도로 가열 할 수있는 것이 없었다. [ 개선의 포인트 ] 열풍 히터를 사용했다. 온도와 열풍 유량을 자동 제어 할 수있는 컨트롤러이 있으므로 신속하게 프로토 타이핑 할 수 있었다.

Read More »제 42 호 합금 입자의 합성

[ 문제점 ] 금속 입자를 간단하게 고온 가열하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 고온 가열 하였다. 금속에 흡수되기 쉬운 근적외선에서 피드백 제어에 임의의 온도에서 안정 가열 하였다. 설비가 소형화 연구비를 신청 쉬워졌다. 게다가 순간적으로 고온 ...

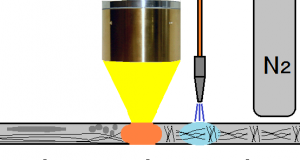

Read More »제 41 호 자성체의 결정 구조 개발

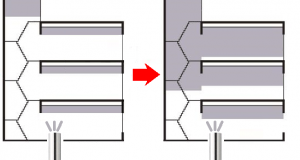

[ 문제점 ] 임의의 온도에서 가열하여 임의의 온도에서 냉각하여 결정 구조를 개발하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 고온 가열 하였다. 빛 가열이므로 냉각용 질소 가스와 간섭하지 않고 온도 프로 파일링을 설정할 수 있었다. 게다가, 설비가 ...

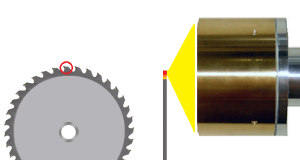

Read More »제 40 호 팁 소의 납땜

[ 문제점 ] 팁 소의 팁을 간단하게 1000℃로 하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하고 고온 가열했다. 전기 설비만으로 가공할 수 있는 것이어 공장의 레이아웃 변경도 기동적으로 할 수 있게 되었다.

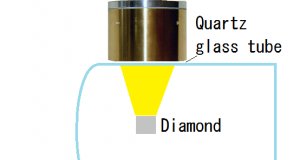

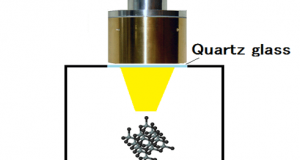

Read More »제 39 호 다이아몬드 양자 센서의 시작

[ 문제점 ] 유리 관내의 다이아몬드를 쉽게 1000 ℃로하는 방법이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 고온 가열 하였다. 설비가 소형화 연구비를 신청 쉬워졌다. 게다가 순식간에 1000 ℃로 가열 할 수 있으므로 선별 효율이 올랐다.

Read More »제 1 호 시험관의 가열

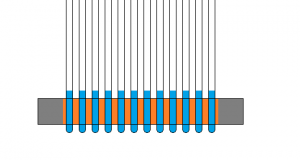

[ 문제점 ] 시험관의 일부를 원적외선으로 가열하는 방법이 없었다. [ 개선의 포인트 ] 원적외선 라인 히터 FLH-30를 사용하고 가열했다. 유리와 액체가 가열할 수 있었다.

Read More »제 1 호 수지의 핀 포인트 가열

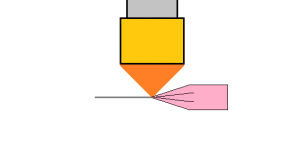

[ 문제점 ] 수지를 핀 포인트 가열 할 수있는 원적외선의 소형 히터가 없었다. [ 개선의 포인트 ] 원적외선 포인트 히터 FPH-30을 사용하여 가열 하였다. 수지의 용착이 부드럽게 잘되었다.

Read More »제 38 호 암석의 고온동력학특성시험

[ 문제점 ] 퇴적軟바위의 고온환경아래에서의 크리프 특성을 파악할 수 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하고 고온 가열했다. 피드백 제어로 임의의 온도로 가열 할 수 있으므로, 크리프 특성의 온도의존성이나, 역학안정성의 파악을 할 수 있었다.

Read More »제6호 용제계 접착제의 건조 시간의 제어

[ 문제점 ] 오버 슈트가없는 안정된 온도에서 일정 시간 양생이 필요했다. [ 개선의 포인트 ] 고기능 히터 콘트롤러 HHC2의 보온 시간 시간 제어 기능을 사용하고, 1초 조각으로 가열 시간을 시험했다. 수지는 오버 슈트에 약하기 때문에 오버 슈트 제로 기능을 사용했다. ...

Read More »제5호 조건 내기위한 가열 시간 제어

[ 문제점 ] 택트 타임 안에서 가열할 수 있을지, 조건 내밀기가 필요했다. [ 개선의 포인트 ] 고기능 히터 콘트롤러 HHC2의 가열 시간 제어 기능을 사용하고, 1초 조각으로 가열 시간을 시험했다. 수지는 오버 슈트에 약하기 때문에 오버 슈트 제로 기능을 사용했다. ...

Read More »제3호 에폭시 수지 패키지의 열 건조 피드백 제어

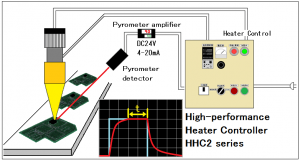

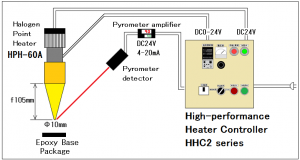

[ 문제점 ] 에폭시 수지 패키지의 건조 시간을 단축하려고 생각하고 있었지만, 비접촉식 온도 제어를 할 수 없었다. [ 개선의 포인트 ] 고기능 히터 콘트롤러 HHC2에 방사 온도계용 온도 조절 그릇을 탑재하고, 방사 온도계의 신호에서 제어했다. 패키지에 접촉하는 일 없이 가열 ...

Read More »제2호 진공 챔버 가열용 할로겐 히터의 피드백 제어

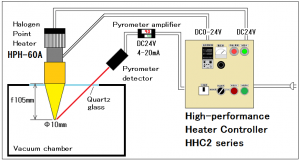

[ 문제점 ] 선형 가속기 · X 선 레이저로 시료를 가열하고 싶어했지만, 진공도가 파괴되므로 할 수 없었다. [ 개선의 포인트 ] 진공 챔버의 뷰포트를 이용하여 가열 제어하기 때문에, 장치의 개조가 필요했다. 고기능 히터 콘트롤러 HHC2에 방사 온도계용 온도 조절 그릇을 ...

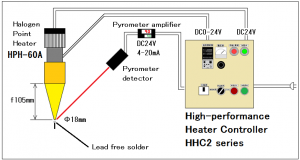

Read More »제1호 납땜 용해 용 할로겐 히터의 피드백 제어

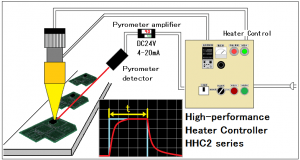

[ 문제점 ] 인쇄 회로 기판의 예열에 할로겐 히터를 사용하고 싶어했지만, 비접촉으로 온도 제어를 할 수 없었다. [ 개선의 포인트 ] 고기능 히터 콘트롤러 HHC2에 방사 온도계용 온도 조절 그릇을 탑재하고, 방사 온도계의 신호에서 제어했다. 기판 위의 소자에 접촉하는 일 ...

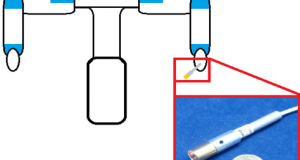

Read More »제 37 호 이중 팔 로봇의 가열 가공

[ 문제점 ] 이중 팔 로봇에 탑재 할 수있는 소형 히터가 없었다. [ 개선의 포인트 ] 초소형 할로겐 포인트 히터 HPH-12을 사용하여 가열 하였다. 길이 95mm 손가락 크기 때문에 핸들링이 편 해졌다.

Read More »제 54 호 붕규산 유리판의 용해

[ 문제점 ] 가스 번갈아서 열원이 없었다. [ 개선의 포인트 ] 할로겐 라인 히터를 사용하여 붕규산 유리판을 용해했다. 전기 설비만으로 유리관 가공 공정을 구성했다. 또한, 소방서의 행정지도를 채웠다.

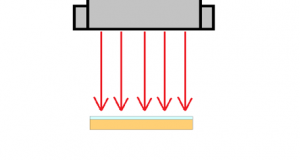

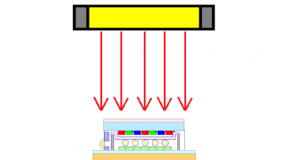

Read More »제 53 호 컬러 필터의 내열 테스트

[ 문제점 ] 컬러 필터의 신규 개발 시간을 단축 할 필요가 있었다. [ 개선의 포인트 ] 평행 광 형 할로겐 라인 히터를 사용했다. 할로겐 가열 형이므로 간단하고 정확하게 가열 할 수 있었다. 시험 시간의 단축에 성공했다.

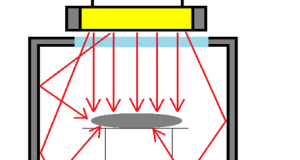

Read More »제 52 호 진공 챔버 내의 시료 가열

[ 문제점 ] 가열 과정을 육안 할 필요가 있었다. [ 개선의 포인트 ] 평행 광 형 할로겐 라인 히터를 사용했다. 가열 변화를 육안으로 확인할 수 있기 때문에 프로세스가 잘 알았다. 시험 시간의 단축에 성공했다.

Read More »제 36 호 설탕의 캐러멜 화

[ 문제점 ] 가스 번갈아서 열원이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 설탕을 캐러멜로했다. 전기 설비만으로 유리관 가공 공정을 구성했다. 또한, 소방서의 행정지도를 채웠다.

Read More »제 35 호 SiC 탄화 규소의 소성

[ 문제점 ] SiC 탄화 규소를 쉽게 가열 할 수있는 열원이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 SiC 탄화 규소를 가열했다. 단시간에 고온이되므로 실험 속도가 올랐다.

Read More »제 34 호 붕규산 유리 관의 용해

[ 문제점 ] 가스 번갈아서 열원이 없었다. [ 개선의 포인트 ] 할로겐 포인트 히터를 사용하여 붕규산 유리 관을 용해했다. 전기 설비만으로 유리관 가공 공정을 구성했다. 또한, 소방서의 행정지도를 채웠다.

Read More »제 104 호 엔진・터빈의 시험

[ 문제점 ] 희박 공기의 가열 기기가 필요했다. [ 개선의 포인트 ] 열풍 히터를 사용하여 터빈을 가열했다. 샤를르의 법칙에 비례한 희박 공기를 얻을 수 있었다.

Read More » HEAT-TECH 최선의 기술 온라인(on-line) 샵

HEAT-TECH 최선의 기술 온라인(on-line) 샵