INDEX

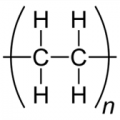

Thermosetting resin is a polymer material, which is also referred to as a thermosetting plastic.

Raw material was fluidized by heating and pressing, it becomes the product shape.

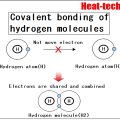

With that configuration to the bound of the monomer with a three-dimensional network structure, it is also referred to as a three-dimensional polymer or cross-linked polymer.

Which was finished in three-dimensional structure is no longer return to the liquid to be heated.

Since this is a chemical change which cures become cross-linked structure by chemical reaction, the cured ones, it does not melt even when heated again, it does not dissolve in the solvent. Therefore, it can not reuse.

The since each other molecules are cross-linked by rigid bonding, thermal decomposition of the polymer occurs when more strongly heated.

In general, it does not dissolve in solvent, but swells in certain solvents.

Molding of thermosetting resin

Place the small molecular weight monomer and the prepolymer that can melting at heating in a linear structure into a metallic mold.

Heating the mold, and the inside of the resin by a chemical reaction, and to complete the cross-linking, to form a three dimensional network of insoluble and infusible.

The thermosetting resin has a substance having a polyfunctional structural units having a functional group which can react to three or more as a starting material.

There is a cross-linking density to those ruling the physical properties of the cured product, this density becomes hard higher, improve heat resistance, but becomes brittle.

When the product molding, by mixing a filler and reinforcing agent to improve mechanical strength, heat resistance, and electrical properties.

Paper, woven fabric, glass mat, etc. can be impregnated with a resin, it has been made widely to make a laminate by application of pressure and heat.

Since the thermosetting resin is hard and resistant to heat and solvents, surface treatment of furniture, such as electrical components and tables, and it is used ashtray, such as in baking paint.

Construction site

When constructing at a site the low viscosity, and completed time is the three-dimensional structure. It is also used much as paint and glue using the advantage quality .

The type to mix and use A liquid (base) and B liquid (hardener) by glue and pate、

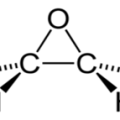

That is using the epoxy pre polymer condensation made Bis Phenol A and epichlorohydrin react to which for epoxy of a proximal pill and is using amine for a hardener.

When mixing the two liquids, and then cured, the adhesive over time, thermosetting manner as graft polymerization takes place three-dimensional polymer.

Thermal properties of thermosetting resin (typical)

| Resin name | Symbol | Density | Specific heat | Thermal conductivity | Thermal expansion coefficient | Continuous heat resistance temp. | Heat distortion temp. |

|---|---|---|---|---|---|---|---|

| Reference temperature 20 ℃ | [g/cm3] | [J/g ℃] | [W/m K] | 10-5/℃ | (℃) | 18.5Kg/cm²/℃ | |

| Phenolic resin (Bakelite) | PF | 1.37-1.46 | 1.57-1.76 | 0.13-0.25 | 2.5~6 | 120 | 115~125 |

| Urea resin (urea resin) | UF | 1.47-1.52 | 1.68 | 0.31-0.43 | 2.2~3.6 | 90 | 125~145 |

| Melamine resin | MF | 1.48 | 1.68 | 0.31-0.43 | 2.9~4.8 | 110~130 | 150~166 |

| Silicone resin | SI | 0.99-1.5 | 1.2-1.4 | 0.15-0.17 | 8~30 | -60~315 | Extensive |

| Epoxy resin | EP | 1.11-1.40 | 1.1 | 0.17-0.22 | 4.5~6.5 | 150~200 | 139~306 |

| Polyurethane | PUR | 1.03-1.50 | 1.9 | 0.12-0.18 | 10~20 | -20~130 | Extensive |

| Unsaturated polyester (alkyd) resin | UP | 1.04-1.46 | 1.09-2.30 | 0.17 | 5.5~10 | 130~150 | 60~204 |

* About the differences between Silicon and Silicone

Silicon is present in nature as the main component of the rocks and soil, and there are many then to the oxygen on the planet.

Silicone is silicon resin. In general term of organic compounds containing silicon, it does not exist in nature.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop