Compare the hot air drying and the infrared ray drying

| Item | Hot air drying | Infrared ray drying |

|---|---|---|

| Reduction of the gas boundary membrane | ◎ | × |

| Removal force of the water vapor | ◎ | × |

| The presence or absence of shadow | ◎ | × |

| Heat absorption index difference of material | ◎ | × |

| Heat transfer | ○ | ◎ |

| Vacuum drying | × | ◎ |

| The rise time of the heater | △ | ◎ |

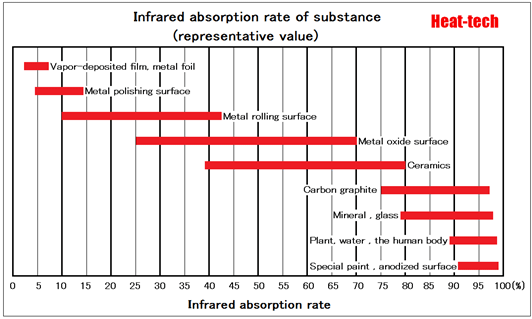

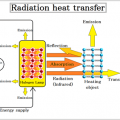

The absorptivity of infrared ray drying is influenced by the form of the surface for heating, a deposits, an oxide film, the crystal grain boundaries, and remaining stress.

Moreover, reflectance is influenced by an objective physical-properties value, surface fine structure, and the objective internal structure.

However, this is hardly no problem in the hot-air drying.

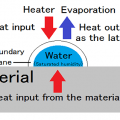

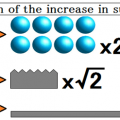

5kW type of the air blow heater will be able to make 300ℓ/min the 800 ℃ of air.

But, it will not be able to make the 1600 ℃ of air even if the output to 2 times of 10kW.

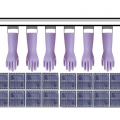

However, if a halogen heater is combined with a hot wind heater, a material surface side will be further made to high temperature.

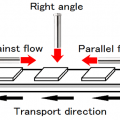

The vapor generated from the surface heated by high temperature is moved by the hot wind, and always fresh dry air is supplied.

It is the strongest combination in which vapor pressure difference is expanded, and also dryness is accelerated.

HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop