[ Problem Point ] We were in trouble various germs to breed. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Bacteria is no longer noticeable.

Read More »No.8 Sterilization of the cooking chamber

[ Problem Point ] We ware in trouble sometimes mold grows. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Mold is no longer noticeable.

Read More »No.7 Sterilization of the prototype chamber

[ Problem Point ] We ware in trouble sometimes mold grows. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Mold is no longer noticeable.

Read More »No.6 Sterilization of quality control room

[ Problem Point ] We were in trouble various germs to breed. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Bacteria is no longer noticeable.

Read More »The heating demonstration of Holing Polyethylene bottle by the Air Blow Heater

This video is the heating demonstration of Holing Polyethylene bottle by the Air Blow Heater. Please check the following site for more information.

Read More »No.5 Sterilization of laboratory

[ Problem Point ] We were in trouble various germs to breed. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Bacteria is no longer noticeable.

Read More »No.4 Sterilization of cold storage warehouse

[ Problem Point ] We ware in trouble sometimes mold grows. [ ⇒Kaizen Point ] We have installed the OZ-20.Since the eradication with ozone and ultraviolet lightMold is no longer noticeable.

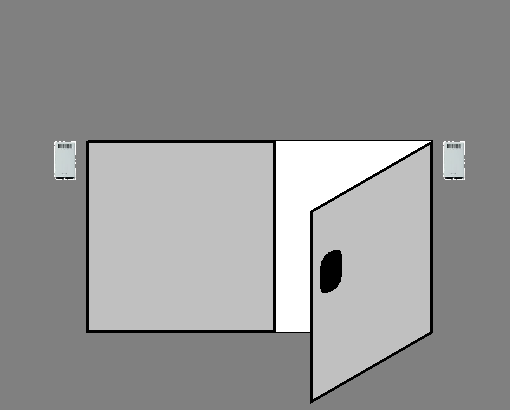

Read More »No.3 Sterilization of large refrigerator

[ Problem Point ] We ware in trouble sometimes mold grows. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Mold is no longer noticeable.

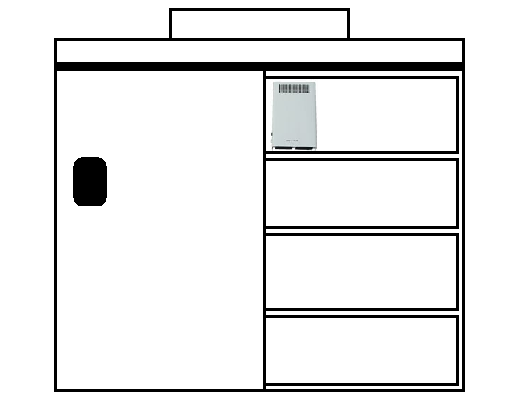

Read More »No.2 Sterilization of plant factory

[ Problem Point ] We ware in trouble sometimes mold grows. [ ⇒Kaizen Point ] We have installed the OZ-20. Since the eradication with ozone and ultraviolet light Mold is no longer noticeable.

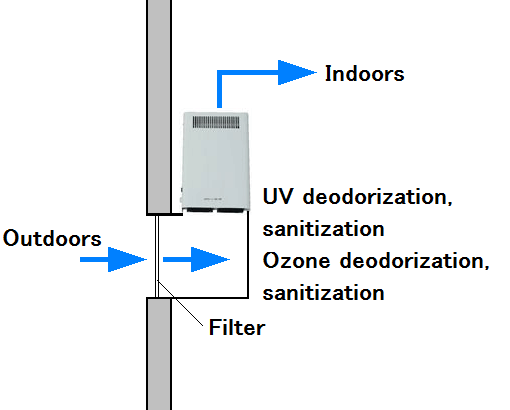

Read More »No.1 Deodorization, sanitization of air inlet

[ Problem Point ] The micro virus which cannot be caught by the filter, it was invaded and troubled. [ ⇒Kaizen Point ] After sterilizing the open air by UV-clean, it put in indoors. The micro virus has been disinfected.

Read More »UV clean Price List

D/# Quantity of ozone outbreak Price US$ OZ-10 10mg/h US$600 OZ-20 20mg/h US$700 Request for quotation

Read More »Leave Sterilizing and Deodorizing to”Ultraviolet-rays and Ozone “Wall-mounted quartz lamp type ozone generator

Leave Sterilizing and Deodorizing to “Ultraviolet-rays and Ozone “ Wall-mounted quartz lamp type ozone generator OZ-10 / OZ-20 OZ-10/OZ-20 is sanitizes and deodorizes by ultraviolet rays and ozone. Sterilize ultraviolet There is a strong effect that kills bacteria and microorganisms ...

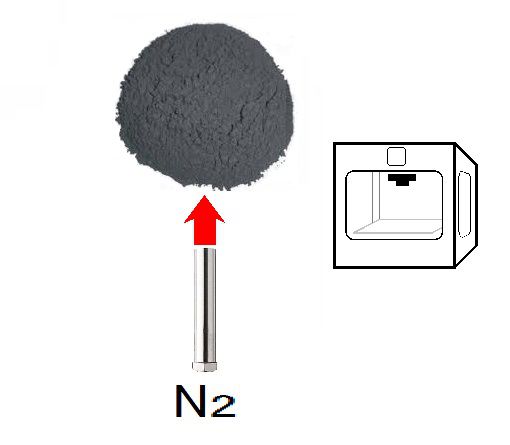

Read More »No.85 Breeze nitrogen heating of powder metal for 3D printer

[ Problem Point ] There was no the Air Blow Heater that can be heated in a nitrogen breeze. [ ⇒Kaizen Point ] We were heated in the breeze by the Air Blow Heater ABH100v-50w/10PS. It is possible to heat ...

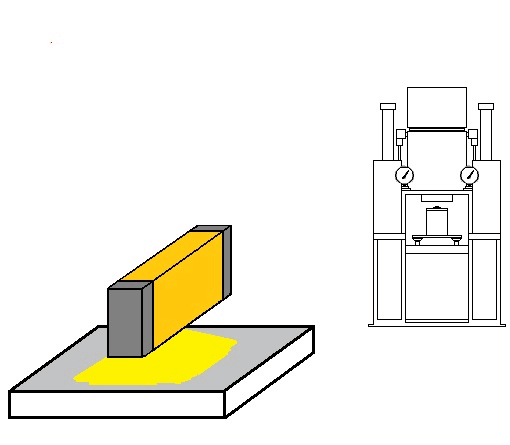

Read More »No.46 Drying and preheating of powder metal

[ Problem Point ] We were looking for can be radiation drying extensively, the heater of powder metals, at high temperatures. [ ⇒Kaizen Point ] We used surface heating type of the Halogen Line Heater.Because it is radiation heating, and ...

Read More »Heating demonstration of Holing PET bottle by the Air Blow Heater

This video is the heating demonstration of Holing PET bottle by the Air Blow Heater. Please check the following site for more information.

Read More »Deburring of polypropylene resin by the Air Blow heater

This video is the heating demonstration of Deburring of polypropylene resin by the Air Blow Heater.

Read More »Heating of corrugated paper by the Air Blow heater

This video is the heating demonstration of a corrugated paper by the Air Blow Heater.

Read More »Heating up HDPE sheet by Air Blow Heater.

This video is a heating demonstration of a HDPE sheet by the Air Blow Heater.

Read More »Heating of the heat shrink tubing with the Halogen Ring Heater

This video is a heating demonstration of a heat shrink tube by the Halogen Ring Heater.

Read More »Aluminum can heating with Halogen Point Heater

This video is a heating demonstration of an aluminum can with the Halogen Point Heater condensing type.

Read More »Melt the wire solder with the Halogen Point Heater

This video is a melting demonstration of a wire solder by the Halogen Point Heater.

Read More »Concrete block heating with halogen line heater

This video is a heating demonstration of a concrete block by the halogen line heater condensing type.

Read More »Copy paper heating with halogen line heater

This video is a heating demonstration of a copy paper by the halogen line heater condensing type.

Read More »Aluminum can heating with halogen line heater

This video is a heating demonstration of an aluminum can with the halogen line heater condensing type.

Read More »Pet Resin bottle heating with halogen line heater

This video is a heating demonstration of a resin bottle with the halogen line heater condensing type.

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop