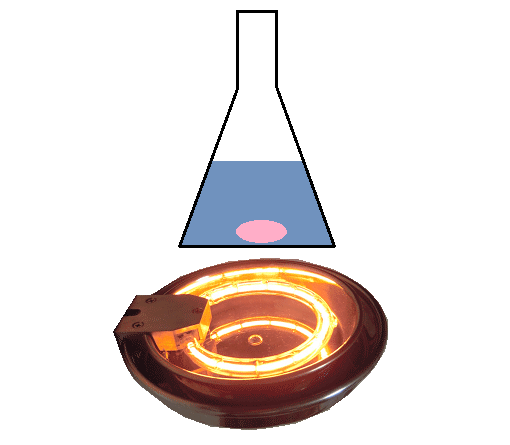

[ Problem Point ] There was no method of building a boiled egg with soft white and hard yellow by a dry method. [ ⇒Kaizen Point ] The halogen ring heater with a dome hood was used. The boiled egg ...

Read More »No.11 Heating the upper part of the test tube

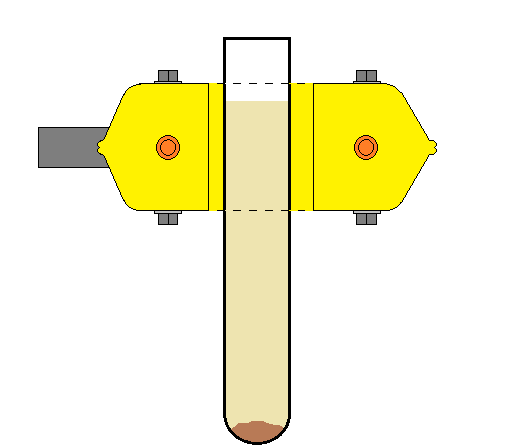

[ Problem Point ] There is no good method of observing the process of heating safely. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. The test tube has been ...

Read More »No.10 Crystallization of the resin

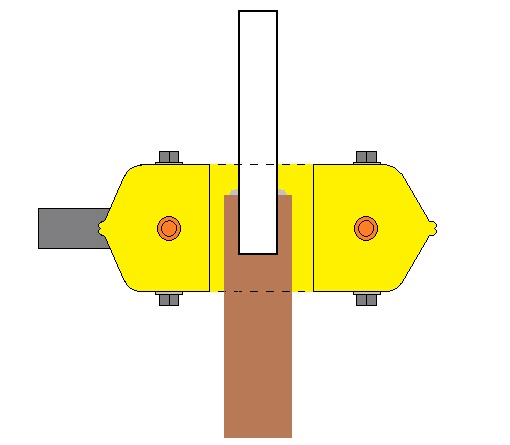

[ Problem Point ] There is no good method of observing the process of heating. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. Since the test piece inserted from ...

Read More »No.9 Silver low attachment of a cylinder work

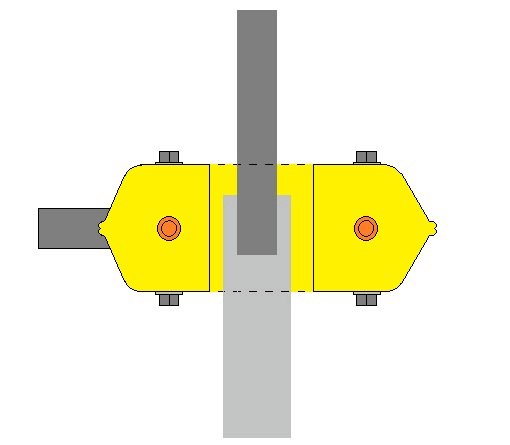

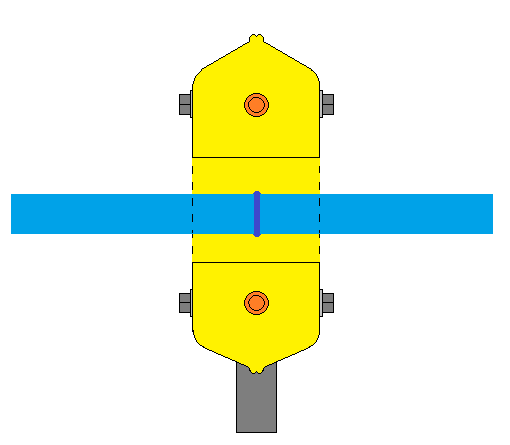

[ Problem Point ] There is no good method of carrying out circular high temperature heating. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was smoothly heated in ...

Read More »No.8 Caulking and heat shrinkage fit of a cylinder work

[ Problem Point ] There is no better way to heat evenly from the periphery. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. It was fitted to the expansion ...

Read More »No.7 Welding rod resin

[ Problem Point ] There is no better way to heat evenly from the periphery. and We were in trouble. [ ⇒Kaizen Point ] The halogen ring heater with a ring hood was used. From the feed port, it is ...

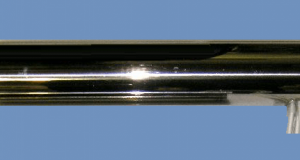

Read More »Protector Tube for Air Blow Heater

Custom-designed will produce the protection tube according to the outside diameter and the length. Ceramic paper of heatproof 1250℃ was used. It becomes dangerous prevention in the Miss touch for a short time that though it is felt it is ...

Read More »Wide Nozzle for Air Blow Heater

It’s most suitable for heating of filamentous work difficult so far. The width of the balloon are 10mm, 15mm and 18.5mm types. Moreover, it is possible to use it as a spatula of air. PDF Catalog Download

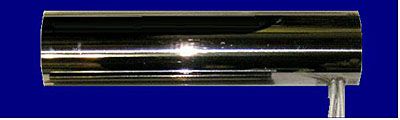

Read More »Needle Nozzle for Air Blow Heater

It can use ABH 口v-□w/10PS. The best for pinpoint heating, difficult until now. Complete lineup to Φ1.0 – Φ6.0 outer diameter. Please use for detailed technical processing and device heating of a printed circuit board. 【 For under 100℃】 【 ...

Read More »《 Platinum heating element Air Blow Heater 》PTH-13N

●Feature of the Platinum heating element Air Blow Heater PTH-13N PTH is a Air Blow Heater using a platinum rhodium alloy heating element. Since the platinum alloy heating element generates heat up to 1700 ℃, high temperature hot air of ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-140X6

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-140X6 The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-102X6

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-102X6 The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-50NM

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-50NM The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-43NM

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-43NM The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-34NM

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-34NM The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-19NM

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-19NM The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

Read More »《 For Clean-room & Semiconductor Air Blow Heater 》DGH-13NM

●Feature of the Clean-room & Semiconductor Air Blow Heater DGH-13NM The DGH series heating element and sensor are also sealed in a capsule of quartz glass. Neither the heating element nor the sensor in direct contact with the heated gas. ...

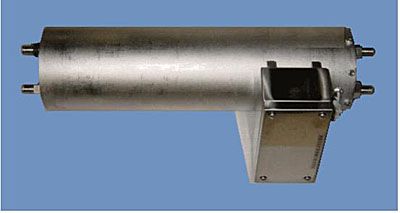

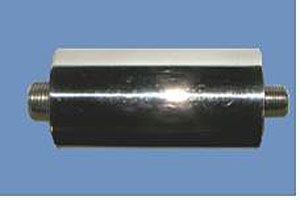

Read More »《Parallel large size Air Blow Heater 》 ABH-102X6

●Parallel large size Air Blow Heater ABH-102X6 This is the simple structure that cut a screw at the both ends of the stainless steel pipe. Connection fittings can be manufactured by our company. The connection metal fittings are available for ...

Read More »《Parallel large size Air Blow Heater 》ABH-61X6

●Parallel large size Air Blow Heater ABH-61X6 This is the simple structure that cut a screw at the both ends of the stainless steel pipe. Connection fittings can be manufactured by our company. The connection metal fittings are available for ...

Read More »《 Parallel large size Air Blow Heater 》ABH-50X6

●Parallel large size Air Blow Heater ABH-50X6 This is the simple structure that cut a screw at the both ends of the stainless steel pipe. Connection fittings can be manufactured by our company. The connection metal fittings are available for ...

Read More »《Parallel large size Air Blow Heater》ABH-38X6

●Parallel large size Air Blow HeaterABH-38X6 This is the simple structure that cut a screw at the both ends of the stainless steel pipe. Connection fittings can be manufactured by our company. The connection metal fittings are available for the ...

Read More »《Robust large size Air Blow Heater 》ABH-43NM

●Feature of the Large size Air Blow Heater ABH-43NM As for the ABH series, heating gas contacts heating element directly. Since adoption of the big high-density heating element of the surface area that heat transfer efficiency has good, can heat ...

Read More »《Robust medium size Air Blow Heater 》ABH-34NM

●Feature of the Medium size Air Blow Heater ABH-18PH As for the ABH series, heating gas contacts heating element directly. The outer diameter is small, but, by adoption of the big high-density heating element of the surface area that heat ...

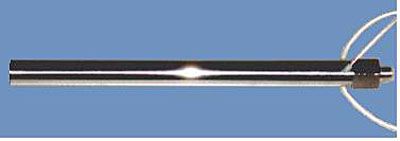

Read More »《Robust medium size Air Blow Heater 》ABH-22N

●Feature of the Medium size Air Blow Heater ABH-22N As for the ABH series, heating gas contacts heating element directly. The outer diameter is small, but, by adoption of the big high-density heating element of the surface area that heat ...

Read More »《 Small size Air Blow Heater 》ABH-19A

●Feature of the Small size Air Blow Heater ABH 19A As for the ABH series, heating gas contacts heating element directly. The outer diameter is small, but, by adoption of the big high-density heating element of the surface area that ...

Read More » HEAT-TECH Best Technology Online Shop

HEAT-TECH Best Technology Online Shop

![[ For Clean-room & Semiconductor Air Blow Heater ] DGH-38PH](https://heater.heat-tech.biz/wp-content/uploads/2012/08/dgh38ph1.jpg)

![[ For Clean-room & Semiconductor Air Blow Heater ] DGH-29PH](https://heater.heat-tech.biz/wp-content/uploads/2012/08/dgh29phsam-300x80.jpg)

![[ For Clean-room & Semiconductor Air Blow Heater ] DGH-15PH](https://heater.heat-tech.biz/wp-content/uploads/2012/08/dgh15ph-en1.jpg)

![[ For Clean-room & Semiconductor Air Blow Heater ] DGH-10PH](https://heater.heat-tech.biz/wp-content/uploads/2012/08/dgh10ph-en1-300x130.jpg)

![[ Medium size Air Blow Heater ]ABH-29PH](https://heater.heat-tech.biz/wp-content/uploads/2012/08/abh29ph1-300x160.jpg)

![[ Small size Air Blow Heater ]ABH-15S](https://heater.heat-tech.biz/wp-content/uploads/2012/08/abh15s-en1-255x160.jpg)